Low-pressure discharges exist within Gas-discharge lamps. The electric discharges in gases are made under gas pressures from a few millitorr to a little less than atmospheric.

Low-pressure discharges exist within Gas-discharge lamps. The electric discharges in gases are made under gas pressures from a few millitorr to a little less than atmospheric.

They are most often used in industry to generate plasma. Less power is required to sustain the discharge at lower pressures as volume-recombination rates are lower. It is also easier to achieve uniform discharges at low pressure.

Normally, the system is pumped down and only necessary plasma gases are then flown into the plasma chamber. Argon is a typical background gas because it has low ionization potential and therefore is easier to break down and sustain.

Most discharges used in the semiconductor industry employ low-pressure plasmas.

Chemical vapor deposition (CVD) is a vacuum deposition method used to produce high quality, and high-performance, solid materials. The process is often used in the semiconductor industry to produce thin films.

A spark gap consists of an arrangement of two conducting electrodes separated by a gap usually filled with a gas such as air, designed to allow an electric spark to pass between the conductors. When the potential difference between the conductors exceeds the breakdown voltage of the gas within the gap, a spark forms, ionizing the gas and drastically reducing its electrical resistance. An electric current then flows until the path of ionized gas is broken or the current reduces below a minimum value called the "holding current". This usually happens when the voltage drops, but in some cases occurs when the heated gas rises, stretching out and then breaking the filament of ionized gas. Usually, the action of ionizing the gas is violent and disruptive, often leading to sound, light and heat.

A corona discharge is an electrical discharge caused by the ionization of a fluid such as air surrounding a conductor carrying a high voltage. It represents a local region where the air has undergone electrical breakdown and become conductive, allowing charge to continuously leak off the conductor into the air. A corona occurs at locations where the strength of the electric field around a conductor exceeds the dielectric strength of the air. It is often seen as a bluish glow in the air adjacent to pointed metal conductors carrying high voltages, and emits light by the same mechanism as a gas discharge lamp.

A plasma afterglow is the radiation emitted from a plasma after the source of ionization is removed. The external electromagnetic fields that sustained the plasma glow are absent or insufficient to maintain the discharge in the afterglow. A plasma afterglow can either be a temporal, due to an interrupted (pulsed) plasma source, or spatial, due to a distant plasma source. In the afterglow, plasma-generated species de-excite and participate in secondary chemical reactions that tend to form stable species. Depending on the gas composition, super-elastic collisions may continue to sustain the plasma in the afterglow for a while by releasing the energy stored in rovibronic degrees of freedom of the atoms and molecules of the plasma. Especially in molecular gases, the plasma chemistry in the afterglow is significantly different from the plasma glow. The afterglow of a plasma is still a plasma and as thus retains most of the properties of a plasma.

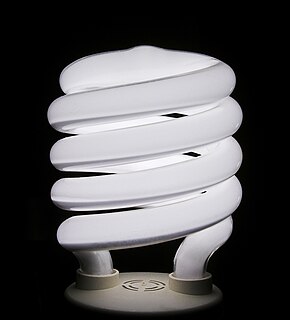

A gas-filled tube, also commonly known as a discharge tube or formerly as a Plücker tube, is an arrangement of electrodes in a gas within an insulating, temperature-resistant envelope. Gas-filled tubes exploit phenomena related to electric discharge in gases, and operate by ionizing the gas with an applied voltage sufficient to cause electrical conduction by the underlying phenomena of the Townsend discharge. A gas-discharge lamp is an electric light using a gas-filled tube; these include fluorescent lamps, metal-halide lamps, sodium-vapor lamps, and neon lights. Specialized gas-filled tubes such as krytrons, thyratrons, and ignitrons are used as switching devices in electric devices.

A glow discharge is a plasma formed by the passage of electric current through a gas. It is often created by applying a voltage between two electrodes in a glass tube containing a low-pressure gas. When the voltage exceeds a value called the striking voltage, the gas ionization becomes self-sustaining, and the tube glows with a colored light. The color depends on the gas used.

A plasma globe or plasma lamp is a clear glass container/ball filled with a mixture of various noble gases with a high-voltage electrode in the center of the container.

An electric arc, or arc discharge, is an electrical breakdown of a gas that produces a prolonged electrical discharge. The current through a normally nonconductive medium such as air produces a plasma; the plasma may produce visible light. An arc discharge is characterized by a lower voltage than a glow discharge and relies on thermionic emission of electrons from the electrodes supporting the arc. An archaic term is voltaic arc, as used in the phrase "voltaic arc lamp".

A plasma torch is a device for generating a directed flow of plasma.

Gas-discharge lamps are a family of artificial light sources that generate light by sending an electric discharge through an ionized gas, a plasma.

A TEA laser is a gas laser energized by a high voltage electrical discharge in a gas mixture generally at or above atmospheric pressure. The most common types are carbon dioxide lasers and excimer lasers, both used extensively in industry and research; less common are nitrogen lasers. The acronym "TEA" stands for Transversely Excited Atmospheric.

Plasma activation is a method of surface modification employing plasma processing, which improves surface adhesion properties of many materials including metals, glass, ceramics, a broad range of polymers and textiles and even natural materials such as wood and seeds. Plasma functionalization also refers to the introduction of functional groups on the surface of exposed materials. It is widely used in industrial processes to prepare surfaces for bonding, gluing, coating and painting. Plasma processing achieves this effect through a combination of reduction of metal oxides, ultra-fine surface cleaning from organic contaminants, modification of the surface topography and deposition of functional chemical groups. Importantly, the plasma activation can be performed at atmospheric pressure using air or typical industrial gases including hydrogen, nitrogen and oxygen. Thus, the surface functionalization is achieved without expensive vacuum equipment or wet chemistry, which positively affects its costs, safety and environmental impact. Fast processing speeds further facilitate numerous industrial applications.

Plasma-enhanced chemical vapor deposition (PECVD) is a chemical vapor deposition process used to deposit thin films from a gas state (vapor) to a solid state on a substrate. Chemical reactions are involved in the process, which occur after creation of a plasma of the reacting gases. The plasma is generally created by radio frequency (RF) frequency or direct current (DC) discharge between two electrodes, the space between which is filled with the reacting gases.

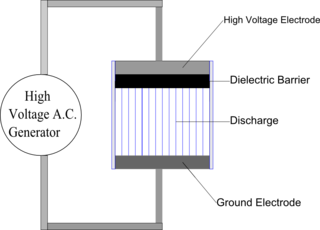

Dielectric-barrier discharge (DBD) is the electrical discharge between two electrodes separated by an insulating dielectric barrier. Originally called silent (inaudible) discharge and also known as ozone production discharge or partial discharge, it was first reported by Ernst Werner von Siemens in 1857.

A microplasma is a plasma of small dimensions, ranging from tens to thousands of micrometers. Microplasmas can be generated at a variety of temperatures and pressures, existing as either thermal or non-thermal plasmas. Non-thermal microplasmas that can maintain their state at standard temperatures and pressures are readily available and accessible to scientists as they can be easily sustained and manipulated under standard conditions. Therefore, they can be employed for commercial, industrial, and medical applications, giving rise to the evolving field of microplasmas.

The 1960s were the incipient period of thermal plasma technology, spurred by the needs of aerospace programs. Among the various methods of thermal plasma generation, induction plasma takes up an important role.

Plasma lamps are a type of electrodeless gas-discharge lamp energized by radio frequency (RF) power. They are distinct from the novelty plasma lamps that were popular in the 1980s.

Plasma is one of the four fundamental states of matter. It consists of a gas of ions – atoms or molecules which have at least one orbital electron stripped and, thus, an electric charge. It is the most abundant form of ordinary matter in the universe, being mostly associated with stars, including the Sun. It extends to the rarefied intracluster medium and possibly to intergalactic regions.

Plasma-activated bonding is a derivative, directed to lower processing temperatures for direct bonding with hydrophilic surfaces. The main requirements for lowering temperatures of direct bonding are the use of materials melting at low temperatures and with different coefficients of thermal expansion (CTE).

An excimer lamp is a source of ultraviolet light produced by spontaneous emission of excimer (exciplex) molecules.