Related Research Articles

Ultraviolet–visible spectroscopy or ultraviolet–visible spectrophotometry refers to absorption spectroscopy or reflectance spectroscopy in part of the ultraviolet and the full, adjacent visible regions of the electromagnetic spectrum. This means it uses light in the visible and adjacent ranges. The absorption or reflectance in the visible range directly affects the perceived color of the chemicals involved. In this region of the spectrum, atoms and molecules undergo electronic transitions. Absorption spectroscopy is complementary to fluorescence spectroscopy, in that fluorescence deals with transitions of electrons from the excited state to the ground state, while absorption measures transitions from the ground state to the excited state.

A pyrometer is a type of remote-sensing thermometer used to measure the temperature of distant objects. Various forms of pyrometers have historically existed. In the modern usage, it is a device that from a distance determines the temperature of a surface from the amount of the thermal radiation it emits, a process known as pyrometry and sometimes radiometry.

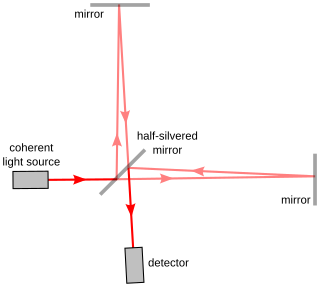

Interferometry is a technique in which waves are superimposed to cause the phenomenon of interference, which is used to extract information. Interferometry typically uses electromagnetic waves and is an important investigative technique in the fields of astronomy, fiber optics, engineering metrology, optical metrology, oceanography, seismology, spectroscopy, quantum mechanics, nuclear and particle physics, plasma physics, remote sensing, biomolecular interactions, surface profiling, microfluidics, mechanical stress/strain measurement, velocimetry, optometry, and making holograms.

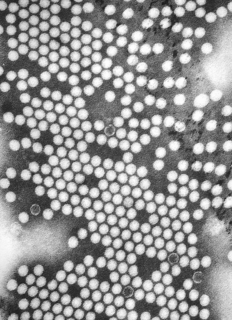

Transmission electron microscopy (TEM) is a microscopy technique in which a beam of electrons is transmitted through a specimen to form an image. The specimen is most often an ultrathin section less than 100 nm thick or a suspension on a grid. An image is formed from the interaction of the electrons with the sample as the beam is transmitted through the specimen. The image is then magnified and focused onto an imaging device, such as a fluorescent screen, a layer of photographic film, or a sensor such as a scintillator attached to a charge-coupled device.

Thermal analysis is a branch of materials science where the properties of materials are studied as they change with temperature. Several methods are commonly used – these are distinguished from one another by the property which is measured:

A monochromator is an optical device that transmits a mechanically selectable narrow band of wavelengths of light or other radiation chosen from a wider range of wavelengths available at the input. The name is from the Greek roots mono-, "single", and chroma, "colour", and the Latin suffix -ator, denoting an agent.

Many ceramic materials, both glassy and crystalline, have found use as optically transparent materials in various forms from bulk solid-state components to high surface area forms such as thin films, coatings, and fibers. Such devices have found widespread use for various applications in the electro-optical field including: optical fibers for guided lightwave transmission, optical switches, laser amplifiers and lenses, hosts for solid-state lasers and optical window materials for gas lasers, and infrared (IR) heat seeking devices for missile guidance systems and IR night vision.

Ellipsometry is an optical technique for investigating the dielectric properties of thin films. Ellipsometry measures the change of polarization upon reflection or transmission and compares it to a model.

Surface metrology is the measurement of small-scale features on surfaces, and is a branch of metrology. Surface primary form, surface fractality and surface roughness are the parameters most commonly associated with the field. It is important to many disciplines and is mostly known for the machining of precision parts and assemblies which contain mating surfaces or which must operate with high internal pressures.

Neutron reflectometry is a neutron diffraction technique for measuring the structure of thin films, similar to the often complementary techniques of X-ray reflectivity and ellipsometry. The technique provides valuable information over a wide variety of scientific and technological applications including chemical aggregation, polymer and surfactant adsorption, structure of thin film magnetic systems, biological membranes, etc.

A dilatometer is a scientific instrument that measures volume changes caused by a physical or chemical process. A familiar application of a dilatometer is the mercury-in-glass thermometer, in which the change in volume of the liquid column is read from a graduated scale. Because mercury has a fairly constant rate of expansion over ambient temperature ranges, the volume changes are directly related to temperature.

Thermomechanical analysis (TMA) is a technique used in thermal analysis, a branch of materials science which studies the properties of materials as they change with temperature.

The disappearing-filament pyrometer is an optical pyrometer, in which the temperature of a glowing incandescent object is measured by comparing it to the light of a heated filament. Invented independently in 1901 by Ludwig Holborn and Ferdinand Kurlbaum in Germany and Harmon Northrup Morse in the United States, it was the first device which could measure temperatures above 1000 °C. Disappearing filament pyrometers have been used to measure temperatures between about 600 °C and 3000 °C. Like other optical pyrometers they are used to measure the temperature of objects too hot for contact thermometers, such as molten metals. Widely used in the steel and ceramics industries as well as for research, they have been almost totally superseded by electronic spectral-band pyrometers.

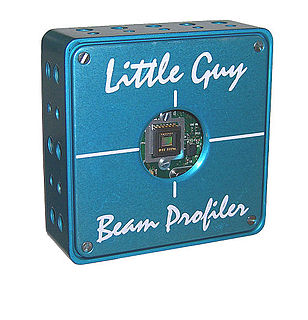

A laser beam profiler captures, displays, and records the spatial intensity profile of a laser beam at a particular plane transverse to the beam propagation path. Since there are many types of lasers — ultraviolet, visible, infrared, continuous wave, pulsed, high-power, low-power — there is an assortment of instrumentation for measuring laser beam profiles. No single laser beam profiler can handle every power level, pulse duration, repetition rate, wavelength, and beam size.

Fourier-transform infrared spectroscopy (FTIR) is a technique used to obtain an infrared spectrum of absorption or emission of a solid, liquid or gas. An FTIR spectrometer simultaneously collects high-resolution spectral data over a wide spectral range. This confers a significant advantage over a dispersive spectrometer, which measures intensity over a narrow range of wavelengths at a time.

A measuring instrument is a device to measure a physical quantity. In the physical sciences, quality assurance, and engineering, measurement is the activity of obtaining and comparing physical quantities of real-world objects and events. Established standard objects and events are used as units, and the process of measurement gives a number relating the item under study and the referenced unit of measurement. Measuring instruments, and formal test methods which define the instrument's use, are the means by which these relations of numbers are obtained. All measuring instruments are subject to varying degrees of instrument error and measurement uncertainty. These instruments may range from simple objects such as rulers and stopwatches to electron microscopes and particle accelerators. Virtual instrumentation is widely used in the development of modern measuring instruments.

The technique of vibrational analysis with scanning probe microscopy allows probing vibrational properties of materials at the submicrometer scale, and even of individual molecules. This is accomplished by integrating scanning probe microscopy (SPM) and vibrational spectroscopy. This combination allows for much higher spatial resolution than can be achieved with conventional Raman/FTIR instrumentation. The technique is also nondestructive, requires non-extensive sample preparation, and provides more contrast such as intensity contrast, polarization contrast and wavelength contrast, as well as providing specific chemical information and topography images simultaneously.

Active thermography is an advanced nondestructive testing procedure, which uses a thermography measurement of a tested material thermal response after its external excitation. This principle can be used also for non-contact infrared non-destructive testing (IRNDT) of materials.

Photo-reflectance is an optical technique for investigating the material and electronic properties of thin films. Photo-reflectance measures the change in reflectivity of a sample in response to the application of an amplitude modulated light beam. In general, a photo-reflectometer consists of an intensity modulated "pump" light beam used to modulate the reflectivity of the sample, a second "probe" light beam used to measure the reflectance of the sample, an optical system for directing the pump and probe beams to the sample, and for directing the reflected probe light onto a photodetector, and a signal processor to record the differential reflectance. The pump light is typically modulated at a known frequency so that a lock-in amplifier may be used to suppress unwanted noise, resulting in the ability to detect reflectance changes at the ppm level.