In organic chemistry, amines (, UK also ) are compounds and functional groups that contain a basic nitrogen atom with a lone pair. Amines are formally derivatives of ammonia, wherein one or more hydrogen atoms have been replaced by a substituent such as an alkyl or aryl group (these may respectively be called alkylamines and arylamines; amines in which both types of substituent are attached to one nitrogen atom may be called alkylarylamines). Important amines include amino acids, biogenic amines, trimethylamine, and aniline; see Category:Amines for a list of amines. Inorganic derivatives of ammonia are also called amines, such as monochloramine (NClH2).

Orange juice is a liquid extract of the orange tree fruit, produced by squeezing or reaming oranges. It comes in several different varieties, including blood orange, navel oranges, valencia orange, clementine, and tangerine. As well as variations in oranges used, some varieties include differing amounts of juice vesicles, known as "pulp" in American English, and "(juicy) bits" in British English. These vesicles contain the juice of the orange and can be left in or removed during the manufacturing process. How juicy these vesicles are depend upon many factors, such as species, variety, and season. In American English, the beverage name is often abbreviated as "OJ".

A sugar substitute is a food additive that provides a sweet taste like that of sugar while containing significantly less food energy than sugar-based sweeteners, making it a zero-calorie or low-calorie sweetener. Artificial sweeteners may be derived through manufacturing of plant extracts or processed by chemical synthesis. Sugar alcohols such as erythritol, xylitol, and sorbitol are derived from sugars. In 2017, sucralose was the most common sugar substitute used in the manufacture of foods and beverages; it had 30% of the global market, which was projected to be valued at $2.8 billion by 2021.

Sodium cyclamate is an artificial sweetener. It is 30–50 times sweeter than sucrose, making it the least potent of the commercially used artificial sweeteners. It is often used with other artificial sweeteners, especially saccharin; the mixture of 10 parts cyclamate to 1 part saccharin is common and masks the off-tastes of both sweeteners. It is less expensive than most sweeteners, including sucralose, and is stable under heating. Safety concerns have led to cyclamates being banned in the United States and other countries, though the European Union considers them as safe.

Acesulfame potassium, also known as acesulfame K or Ace K, is a calorie-free sugar substitute often marketed under the trade names Sunett and Sweet One. In the European Union, it is known under the E number E950. It was discovered accidentally in 1967 by German chemist Karl Clauss at Hoechst AG. In chemical structure, acesulfame potassium is the potassium salt of 6-methyl-1,2,3-oxathiazine-4(3H)-one 2,2-dioxide. It is a white crystalline powder with molecular formula C

4H

4KNO

4S and a molecular weight of 201.24 g/mol.

Acid gas is a particular typology of natural gas or any other gas mixture containing significant quantities of hydrogen sulfide (H2S), carbon dioxide (CO2), or similar acidic gases.

Sour gas is natural gas or any other gas containing significant amounts of hydrogen sulfide (H2S).

Amine gas treating, also known as amine scrubbing, gas sweetening and acid gas removal, refers to a group of processes that use aqueous solutions of various alkylamines (commonly referred to simply as amines) to remove hydrogen sulfide (H2S) and carbon dioxide (CO2) from gases. It is a common unit process used in refineries, and is also used in petrochemical plants, natural gas processing plants and other industries.

Flue gas is the gas exiting to the atmosphere via a flue, which is a pipe or channel for conveying exhaust gases from a fireplace, oven, furnace, boiler or steam generator. Quite often, the flue gas refers to the combustion exhaust gas produced at power plants. Its composition depends on what is being burned, but it will usually consist of mostly nitrogen derived from the combustion of air, carbon dioxide, and water vapor as well as excess oxygen. It further contains a small percentage of a number of pollutants, such as particulate matter, carbon monoxide, nitrogen oxides, and sulfur oxides.

Sour crude oil is crude oil containing a high amount of the impurity sulfur. It is common to find crude oil containing some impurities. When the total sulfur level in the oil is more than 0.5% the oil is called "sour".

Agave syrup, aka maguey syrup, and commonly though inaccurately known as agave nectar, is a sweetener commercially produced from several species of agave, including Agave tequilana and Agave salmiana. Blue-agave syrup contains 56% fructose as a sugar providing sweetening properties.

Merox is an acronym for mercaptan oxidation. It is a proprietary catalytic chemical process developed by UOP used in oil refineries and natural gas processing plants to remove mercaptans from LPG, propane, butanes, light naphthas, kerosene and jet fuel by converting them to liquid hydrocarbon disulfides.

Chocolate is a range of foods derived from cocoa (cacao), mixed with fat and finely powdered sugar to produce a solid confectionery. There are several types of chocolate, classified according to the proportion of cocoa used in a particular formulation.

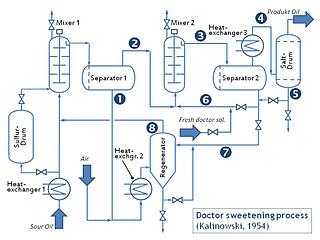

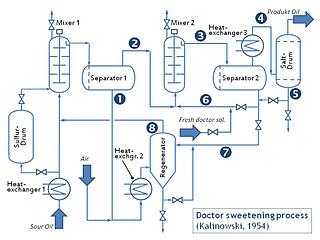

The doctor sweetening process is an industrial chemical process for converting mercaptans in sour gasoline into disulfides. Sulfur compounds darken gasoline, give it an offensive odor and increase toxic sulfur dioxide engine emissions. However, this process only reduces the odor.

An oil production plant is a facility which processes production fluids from oil wells in order to separate out key components and prepare them for export. This is distinct from an oil depot, which does not have processing facilities.

Natural gas has been used almost as long as crude oil in Canada, but its commercial development was not as rapid. This is because of special properties of this energy commodity: it is a gas, and it frequently contains impurities. The technical challenges involved to first process and then pipe it to market are therefore considerable. Furthermore, the costs of pipeline building make the whole enterprise capital intensive, requiring both money and engineering expertise, and large enough markets to make the business profitable.

ProMax is a chemical process simulator for process troubleshooting and design, developed and sold by Bryan Research and Engineering, Inc. Initially released in late 2005, ProMax is a continuance of two previous process simulators, PROSIM and TSWEET. ProMax is considered the industry standard for designing amine gas treating and glycol dehydration units.

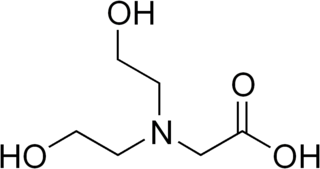

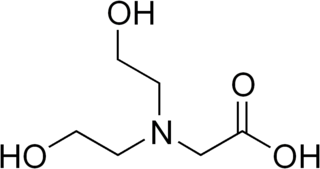

Bicine is an organic compound used as a buffering agent. It is one of Good's buffers and has a pKa of 8.35 at 20 °C. It is prepared by the reaction of glycine with ethylene oxide, followed by hydrolysis of the resultant lactone.

CrystaSulf is the trade name for a chemical process used for removing hydrogen sulfide (H2S) from natural gas, synthesis gas and other gas streams in refineries and chemical plants. CrystaSulf uses a modified liquid-phase Claus reaction to convert the hydrogen sulfide (H2S) into elemental sulfur which is then removed from the process by filtration. CrystaSulf is used in the energy industry as a mid-range process to handle sulfur amounts between 0.1 and 20 tons per day. Below 0.1 tons of sulfur per day is typically managed by H2S Scavengers and applications above 20 tons per day are typically treated with the Amine – Claus process.