A winch is a mechanical device that is used to pull in or let out or otherwise adjust the tension of a rope or wire rope.

A zipper, zip, fly, or zip fastener, formerly known as a clasp locker, is a commonly used device for binding together two edges of fabric or other flexible material. Used in clothing, luggage and other bags, camping gear, and many other items, zippers come in a wide range of sizes, shapes, and colors. In 1892, Whitcomb L. Judson, an American inventor from Chicago, patented the original design from which the modern device evolved.

Webbing is a strong fabric woven as a flat strip or tube of varying width and fibres, often used in place of rope. It is a versatile component used in climbing, slacklining, furniture manufacturing, automobile safety, auto racing, towing, parachuting, military apparel, load securing, and many other fields.

A fastener or fastening is a hardware device that mechanically joins or affixes two or more objects together. In general, fasteners are used to create non-permanent joints; that is, joints that can be removed or dismantled without damaging the joining components. Steel fasteners are usually made of stainless steel, carbon steel, or alloy steel.

A strap, sometimes also called strop, is an elongated flap or ribbon, usually of leather or other flexible materials.

A cable tie is a type of fastener for holding items together, primarily electrical cables and wires. Because of their low cost, ease of use, and binding strength, cable ties are ubiquitous, finding use in a wide range of other applications. Cable ties were first manufactured by Thomas & Betts under the brand name Ty-Rap.

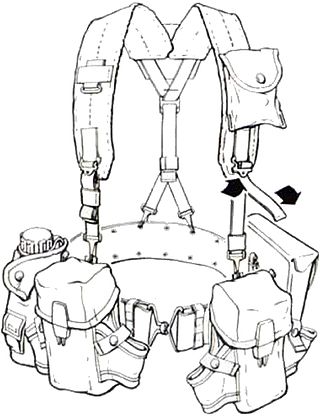

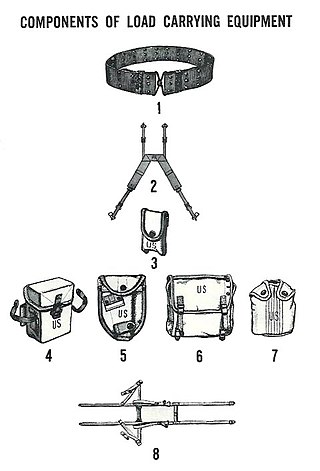

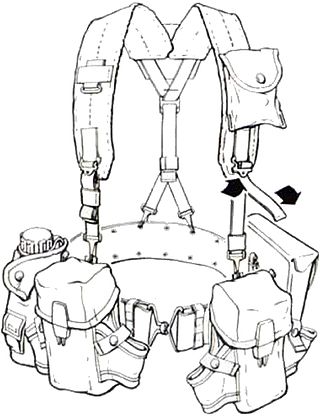

Personal Load Carrying Equipment (PLCE) is one of several tactical webbing systems of the British Armed Forces. Dependent upon the year of design, and the decade of introduction, the webbing system was named and is commonly referred to as the 85 Pattern, the 90 Pattern or the 95 Pattern webbing.

A Prusik is a friction hitch or knot used to attach a loop of cord around a rope, applied in climbing, canyoneering, mountaineering, caving, rope rescue, ziplining, and by arborists. The term Prusik is a name for both the loops of cord used to tie the hitch and the hitch itself, and the verb is "to prusik" or "prusiking". More casually, the term is used for any friction hitch or device that can grab a rope. Due to the pronunciation, the word is often misspelled Prussik, Prussick, or Prussic.

A belt buckle is a buckle, a clasp for fastening two ends, such as of straps or a belt, in which a device attached to one of the ends is fitted or coupled to the other. The word enters Middle English via Old French and the Latin buccula or "cheek-strap," as for a helmet. Belt buckles and other fixtures are used on a variety of belts, including cingula, baltea, baldrics and later waist-belts.

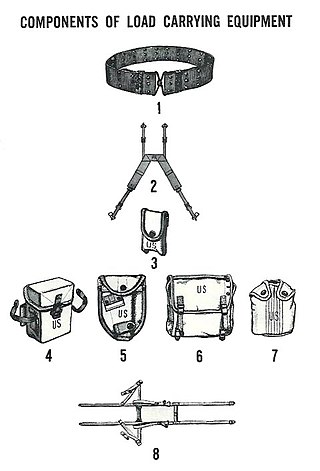

The All-Purpose Lightweight Individual Carrying Equipment (ALICE) is a set of load-carrying equipment adopted as United States Army Standard A on 17 January 1973 to replace the M-1956 Individual Load-Carrying Equipment (ILCE) and M-1967 Modernized Load-Carrying Equipment (MLCE). Although since superseded by MOLLE, ALICE gear is still in some limited use with the U.S. Army National Guard, State Guard, also some ground units of the Navy and Air Force.

The IIFS was introduced in 1988, to serve as a fighting and existence carrying system—a possible replacement for the All-purpose Lightweight Individual Carrying Equipment employed and fielded by United States Armed Forces since 1973.

Tie down hardware is used to turn webbing into a tie down strap. There are various categories of tie down strap hardware that allow for the creation of a virtually unlimited number of different types of tie down straps. These pieces of hardware fall into several categories including fasteners, end fittings, and buckles.

A flatbed truck is a type of truck the bodywork of which is just an entirely flat, level 'bed' with no sides or roof. This allows for quick and easy loading of goods, and consequently they are used to transport heavy loads that are not delicate or vulnerable to rain, and also for abnormal loads that require more space than is available on a closed body. Flatbed trucks can be either articulated or rigid.

The M-1956 Load-Carrying Equipment (LCE), also known as the Individual Load-Carrying Equipment (ILCE), was developed by the U.S. Army and first issued in the early 1960s. The M-1956 LCE was designed to replace the M-1945 Combat Pack, the M-1923 cartridge belt, the M-1936 pistol belt and the M-1937 BAR magazine belt. The M-1956 LCE was designed to be quickly configured, using no tools, to accommodate various mission and ammunition loads. The M-1956 LCE remained in service through the 1980s and set the standard for future United States military load-carrying equipment.

Load securing, also known as cargo securing, is the securing of cargo for transportation. According to the European Commission Transportation Department “it has been estimated that up to 25% of accidents involving trucks can be attributable to inadequate cargo securing”. Cargo that is improperly secured can cause severe accidents and lead to the loss of cargo, lives, and vehicles, or cause environmental hazards.

1937 Pattern Web Equipment was an item of military load-carrying equipment. It replaced the 1908 Pattern and 1925 Pattern—on which it was based—and was standard issue for British and Commonwealth troops from its introduction in 1937, throughout World War II, and in the post-war period until it was superseded by 1958 Pattern Web Equipment. It remained in limited use with Territorial Army and other second-line troops until the mid to late 1970s. Official use of the webbing in Community Cadet Forces and the Combined Cadet Force persisted into the 1980s.

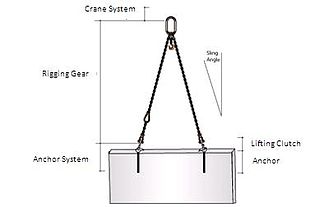

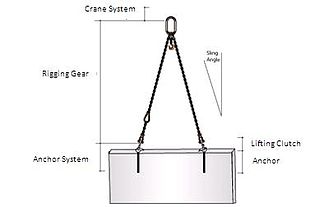

Rigging is both a noun, the equipment, and verb, the action of designing and installing the equipment, in the preparation to move objects. A team of riggers design and install the lifting or rolling equipment needed to raise, roll, slide or lift objects such as heavy machinery, structural components, building materials, or large-scale fixtures with a crane, hoist or block and tackle.

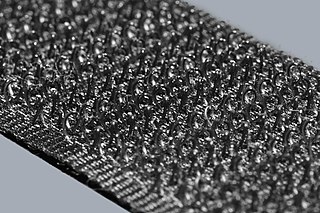

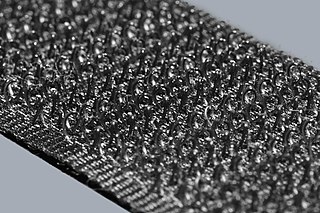

Hook-and-loop fasteners, hook-and-pile fasteners or touch fasteners, are a method for allowing two surfaces to be repeatedly fastened and unfastened, useful for clothing or other purposes. The fastener consists of two components: typically, two lineal fabric strips which are attached to the opposing surfaces designed to be fastened together. The first component features tiny hooks and the second component features smaller loops; When the two are pressed together, the hooks catch in the loops and the two pieces fasten or bind temporarily. When separated, which can be done by pulling or peeling the two surfaces apart, the strips make a distinctive ripping sound.

A bolt snap is a type of snap hook with a manually operated bolt action slide gate of medium security used to clip a light load to a ring, eye, loop or bight to temporarily secure or suspend an object. They are used for a wide variety of applications including dog leads and for clipping scuba equipment to the diving harness. A similar but more secure device used to attach sails to a stay is known as a piston hank. It differs from a snap shackle in that the load is not carried by the gate. The bolt snap must be actively operated by the user to clip or unclip, and is not easily snagged or unintentionally clipped or unclipped by pressing or bumping against the surroundings.