It has been requested that the title of this article be changed to Tempered Glass. Please see the relevant discussion on the discussion page. Do not move the page until the discussion has reached consensus for the change and is closed. |

This article needs additional citations for verification .(January 2009) (Learn how and when to remove this template message) |

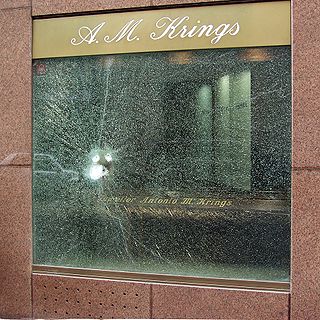

Toughened or tempered glass is a type of safety glass processed by controlled thermal or chemical treatments to increase its strength compared with normal glass. Tempering puts the outer surfaces into compression and the interior into tension. Such stresses cause the glass, when broken, to crumble into small granular chunks instead of splintering into jagged shards as plate glass (a.k.a. annealed glass) does. The granular chunks are less likely to cause injury.

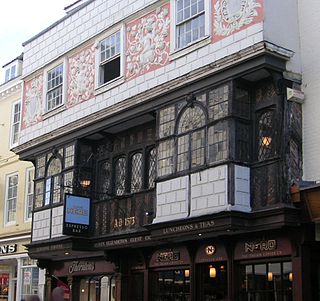

Safety glass is glass with additional safety features that make it less likely to break, or less likely to pose a threat when broken. Common designs include toughened glass, laminated glass, wire mesh glass and engraved glass. Wire mesh glass was invented by Frank Shuman. Laminated glass was invented in 1903 by the French chemist Édouard Bénédictus (1878–1930).

In mechanics, compression is the application of balanced inward ("pushing") forces to different points on a material or structure, that is, forces with no net sum or torque directed so as to reduce its size in one or more directions. It is contrasted with tension or traction, the application of balanced outward ("pulling") forces; and with shearing forces, directed so as to displace layers of the material parallel to each other. The compressive strength of materials and structures is an important engineering consideration.

In physics, tension may be described as the pulling force transmitted axially by the means of a string, cable, chain, or similar one-dimensional continuous object, or by each end of a rod, truss member, or similar three-dimensional object; tension might also be described as the action-reaction pair of forces acting at each end of said elements. Tension could be the opposite of compression.

Contents

- Properties

- Uses

- Buildings and structures

- Household uses

- Food service

- Cooking and baking

- Mobile devices

- Manufacturing

- Disadvantages

- History

- See also

- References

As a result of its safety and strength, toughened glass is used in a variety of demanding applications, including passenger vehicle windows, shower doors, architectural glass doors and tables, refrigerator trays, mobile screen protectors, as a component of bulletproof glass, for diving masks, and various types of plates and cookware.

Bulletproof glass is a strong and optically transparent material that is particularly resistant to penetration by projectiles. Like any material, it is not completely impenetrable. It is usually made from a combination of two or more types of glass, one hard and one soft. The softer layer makes the glass more elastic, so it can flex instead of shatter. The index of refraction for both of the glasses used in the bulletproof layers must be almost the same to keep the glass transparent and allow a clear, undistorted view through the glass. Bulletproof glass varies in thickness from 3⁄4 to 3 1⁄2 inches.

A diving mask is an item of diving equipment that allows underwater divers, including scuba divers, free-divers, and snorkelers, to see clearly underwater. Surface supplied divers usually use a full face mask or diving helmet, but in some systems the half mask may be used. When the human eye is in direct contact with water as opposed to air, its normal environment, light entering the eye is refracted by a different angle and the eye is unable to focus the light on the retina. By providing an air space in front of the eyes, the eye is able to focus nearly normally. The shape of the air space in the mask slightly affects the ability to focus. Corrective lenses can be fitted to the inside surface of the viewport or contact lenses may be worn inside the mask to allow normal vision for people with focusing defects.