Engineering is the practice of using natural science, mathematics, and the engineering design process to solve technical problems, increase efficiency and productivity, and improve systems. Modern engineering comprises many subfields which include designing and improving infrastructure, machinery, vehicles, electronics, materials, and energy systems.

Nuclear engineering is the engineering discipline concerned with designing and applying systems that utilize the energy released by nuclear processes. The most prominent application of nuclear engineering is the generation of electricity. Worldwide, some 440 nuclear reactors in 32 countries generate 10 percent of the world's energy through nuclear fission. In the future, it is expected that nuclear fusion will add another nuclear means of generating energy. Both reactions make use of the nuclear binding energy released when atomic nucleons are either separated (fission) or brought together (fusion). The energy available is given by the binding energy curve, and the amount generated is much greater than that generated through chemical reactions. Fission of 1 gram of uranium yields as much energy as burning 3 tons of coal or 600 gallons of fuel oil, without adding carbon dioxide to the atmosphere.

Paper engineering is a branch of engineering that deals with the usage of physical science and life sciences in conjunction with mathematics as applied to the converting of raw materials into useful paper products and co-products. The field applies various principles in process engineering and unit operations to the manufacture of paper, chemicals, energy and related materials. The following timeline shows some of the key steps in the development of the science of chemical and bioprocess engineering:

A chemical engineer is a professional equipped with the knowledge of chemistry and other basic sciences who works principally in the chemical industry to convert basic raw materials into a variety of products and deals with the design and operation of plants and equipment. This person applies the principles of chemical engineering in any of its various practical applications, such as

- Design, manufacture, and operation of plants and machinery in industrial chemical and related processes ;

- Development of new or adapted substances for products ranging from foods and beverages to cosmetics to cleaners to pharmaceutical ingredients, among many other products ;

- Development of new technologies such as fuel cells, hydrogen power and nanotechnology, as well as working in fields wholly or partially derived from chemical engineering such as materials science, polymer engineering, and biomedical engineering. This can include working of geophysical projects such as rivers, stones, and signs.

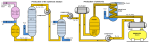

Process engineering is the understanding and application of the fundamental principles and laws of nature that allow humans to transform raw material and energy into products that are useful to society, at an industrial level. By taking advantage of the driving forces of nature such as pressure, temperature and concentration gradients, as well as the law of conservation of mass, process engineers can develop methods to synthesize and purify large quantities of desired chemical products. Process engineering focuses on the design, operation, control, optimization and intensification of chemical, physical, and biological processes. Process engineering encompasses a vast range of industries, such as agriculture, automotive, biotechnical, chemical, food, material development, mining, nuclear, petrochemical, pharmaceutical, and software development. The application of systematic computer-based methods to process engineering is "process systems engineering".

In chemical engineering and related fields, a unit operation is a basic step in a process. Unit operations involve a physical change or chemical transformation such as separation, crystallization, evaporation, filtration, polymerization, isomerization, and other reactions. For example, in milk processing, the following unit operations are involved: homogenization, pasteurization, and packaging. These unit operations are connected to create the overall process. A process may require many unit operations to obtain the desired product from the starting materials, or feedstocks.

A chemical reactor is an enclosed volume in which a chemical reaction takes place. In chemical engineering, it is generally understood to be a process vessel used to carry out a chemical reaction, which is one of the classic unit operations in chemical process analysis. The design of a chemical reactor deals with multiple aspects of chemical engineering. Chemical engineers design reactors to maximize net present value for the given reaction. Designers ensure that the reaction proceeds with the highest efficiency towards the desired output product, producing the highest yield of product while requiring the least amount of money to purchase and operate. Normal operating expenses include energy input, energy removal, raw material costs, labor, etc. Energy changes can come in the form of heating or cooling, pumping to increase pressure, frictional pressure loss or agitation.

A chemical plant is an industrial process plant that manufactures chemicals, usually on a large scale. The general objective of a chemical plant is to create new material wealth via the chemical or biological transformation and or separation of materials. Chemical plants use specialized equipment, units, and technology in the manufacturing process. Other kinds of plants, such as polymer, pharmaceutical, food, and some beverage production facilities, power plants, oil refineries or other refineries, natural gas processing and biochemical plants, water and wastewater treatment, and pollution control equipment use many technologies that have similarities to chemical plant technology such as fluid systems and chemical reactor systems. Some would consider an oil refinery or a pharmaceutical or polymer manufacturer to be effectively a chemical plant.

Indira Gandhi Centre for Atomic Research (IGCAR) is one of India's premier nuclear research centres. It is the second largest establishment of the Department of Atomic Energy (DAE), next to Bhabha Atomic Research Centre (BARC), located at Kalpakkam, 80 km south of Chennai, India. It was established in 1971 as an exclusive centre dedicated to the pursuit of fast reactor science and technology, due to the vision of Vikram Sarabhai. Originally, it was called Reactor Research Centre (RRC). It was renamed to Indira Gandhi Centre for Atomic Research (IGCAR) by the then Prime Minister of India Rajiv Gandhi in December 1985. The centre is engaged in broad-based multidisciplinary programme of scientific research and advanced engineering directed towards the development of fast breeder reactor technology in India.

In chemical engineering, process design is the choice and sequencing of units for desired physical and/or chemical transformation of materials. Process design is central to chemical engineering, and it can be considered to be the summit of that field, bringing together all of the field's components.

In chemical processing, a packed bed is a hollow tube, pipe, or other vessel that is filled with a packing material. The packed bed can be randomly filled with small objects like Raschig rings or else it can be a specifically designed structured packing. Packed beds may also contain catalyst particles or adsorbents such as zeolite pellets, granular activated carbon, etc.

Chemical engineering is a discipline that was developed out of those practicing "industrial chemistry" in the late 19th century. Before the Industrial Revolution, industrial chemicals and other consumer products such as soap were mainly produced through batch processing. Batch processing is labour-intensive and individuals mix predetermined amounts of ingredients in a vessel, heat, cool or pressurize the mixture for a predetermined length of time. The product may then be isolated, purified and tested to achieve a saleable product. Batch processes are still performed today on higher value products, such as pharmaceutical intermediates, speciality and formulated products such as perfumes and paints, or in food manufacture such as pure maple syrups, where a profit can still be made despite batch methods being slower and inefficient in terms of labour and equipment usage. Due to the application of Chemical Engineering techniques during manufacturing process development, larger volume chemicals are now produced through continuous "assembly line" chemical processes. The Industrial Revolution was when a shift from batch to more continuous processing began to occur. Today commodity chemicals and petrochemicals are predominantly made using continuous manufacturing processes whereas speciality chemicals, fine chemicals and pharmaceuticals are made using batch processes.

In the chemical and process industries, a process has inherent safety if it has a low level of danger even if things go wrong. Inherent safety contrasts with other processes where a high degree of hazard is controlled by protective systems. As perfect safety cannot be achieved, common practice is to talk about inherently safer design. “An inherently safer design is one that avoids hazards instead of controlling them, particularly by reducing the amount of hazardous material and the number of hazardous operations in the plant.”

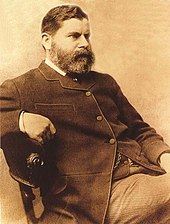

Warren Kendall Lewis was an MIT professor who has been called the father of modern chemical engineering. He co-authored an early major textbook on the subject which essentially introduced the concept of unit operations. He also co-developed the Houdry process under contract to The Standard Oil Company of New Jersey into modern fluid catalytic cracking with Edwin R. Gilliland, another MIT professor.

Perry's Chemical Engineers' Handbook was first published in 1934 and the most current ninth edition was published in July 2018. It has been a source of chemical engineering knowledge for chemical engineers, and a wide variety of other engineers and scientists, through eight previous editions spanning more than 80 years.

The following outline is provided as an overview of and topical guide to chemical engineering:

A fluidized bed reactor (FBR) is a type of reactor device that can be used to carry out a variety of multiphase chemical reactions. In this type of reactor, a fluid is passed through a solid granular material at high enough speeds to suspend the solid and cause it to behave as though it were a fluid. This process, known as fluidization, imparts many important advantages to an FBR. As a result, FBRs are used for many industrial applications.

Process safety is an interdisciplinary engineering domain focusing on the study, prevention, and management of large-scale fires, explosions and chemical accidents in process plants or other facilities dealing with hazardous materials, such as refineries and oil and gas production installations. Thus, process safety is generally concerned with the prevention of, control of, mitigation of and recovery from unintentional hazardous materials releases that can have a serious effect to people, plant and/or the environment.

Industrial engineering is an engineering profession that is concerned with the optimization of complex processes, systems, or organizations by developing, improving and implementing integumentary systems of people, money, knowledge, information and equipment. Industrial engineering is central to manufacturing operations.

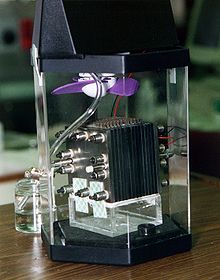

Electrochemical engineering is the branch of chemical engineering dealing with the technological applications of electrochemical phenomena, such as electrosynthesis of chemicals, electrowinning and refining of metals, flow batteries and fuel cells, surface modification by electrodeposition, electrochemical separations and corrosion.