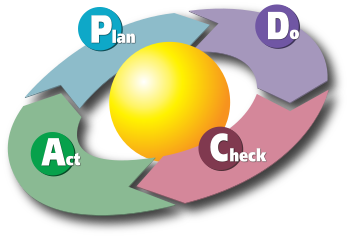

A quality management system (QMS) is a collection of business processes focused on consistently meeting customer requirements and enhancing their satisfaction. It is aligned with an organization's purpose and strategic direction. It is expressed as the organizational goals and aspirations, policies, processes, documented information, and resources needed to implement and maintain it. Early quality management systems emphasized predictable outcomes of an industrial product production line, using simple statistics and random sampling. By the 20th century, labor inputs were typically the most costly inputs in most industrialized societies, so focus shifted to team cooperation and dynamics, especially the early signaling of problems via a continual improvement cycle. In the 21st century, QMS has tended to converge with sustainability and transparency initiatives, as both investor and customer satisfaction and perceived quality are increasingly tied to these factors. Of QMS regimes, the ISO 9000 family of standards is probably the most widely implemented worldwide – the ISO 19011 audit regime applies to both and deals with quality and sustainability and their integration.

The ISO 9000 family is a set of five quality management systems (QMS) standards by the International Organization for Standardization (ISO) that help organizations ensure they meet customer and other stakeholder needs within statutory and regulatory requirements related to a product or service. ISO 9000 deals with the fundamentals of QMS, including the seven quality management principles that underlie the family of standards. ISO 9001 deals with the requirements that organizations wishing to meet the standard must fulfill. ISO 9002 is a model for quality assurance in production and installation. ISO 9003 for quality assurance in final inspection and test. ISO 9004 gives guidance on achieving sustained organizational success.

Hazard analysis and critical control points, or HACCP, is a systematic preventive approach to food safety from biological, chemical, and physical hazards in production processes that can cause the finished product to be unsafe and designs measures to reduce these risks to a safe level. In this manner, HACCP attempts to avoid hazards rather than attempting to inspect finished products for the effects of those hazards. The HACCP system can be used at all stages of a food chain, from food production and preparation processes including packaging, distribution, etc. The Food and Drug Administration (FDA) and the United States Department of Agriculture (USDA) require mandatory HACCP programs for juice and meat as an effective approach to food safety and protecting public health. Meat HACCP systems are regulated by the USDA, while seafood and juice are regulated by the FDA. All other food companies in the United States that are required to register with the FDA under the Public Health Security and Bioterrorism Preparedness and Response Act of 2002, as well as firms outside the US that export food to the US, are transitioning to mandatory hazard analysis and risk-based preventive controls (HARPC) plans.

In science and engineering, root cause analysis (RCA) is a method of problem solving used for identifying the root causes of faults or problems. It is widely used in IT operations, manufacturing, telecommunications, industrial process control, accident analysis, medicine, healthcare industry, etc. Root cause analysis is a form of inductive and deductive inference.

Statistical process control (SPC) or statistical quality control (SQC) is the application of statistical methods to monitor and control the quality of a production process. This helps to ensure that the process operates efficiently, producing more specification-conforming products with less waste scrap. SPC can be applied to any process where the "conforming product" output can be measured. Key tools used in SPC include run charts, control charts, a focus on continuous improvement, and the design of experiments. An example of a process where SPC is applied is manufacturing lines.

Current good manufacturing practices (cGMP) are those conforming to the guidelines recommended by relevant agencies. Those agencies control the authorization and licensing of the manufacture and sale of food and beverages, cosmetics, pharmaceutical products, dietary supplements, and medical devices. These guidelines provide minimum requirements that a manufacturer must meet to assure that their products are consistently high in quality, from batch to batch, for their intended use. The rules that govern each industry may differ significantly; however, the main purpose of GMP is always to prevent harm from occurring to the end user. Additional tenets include ensuring the end product is free from contamination, that it is consistent in its manufacture, that its manufacture has been well documented, that personnel are well trained, and that the product has been checked for quality more than just at the end phase. GMP is typically ensured through the effective use of a quality management system (QMS).

Software maintenance in software engineering is the modification of a software product after delivery to correct faults, to improve performance or other attributes.

Quality management ensures that an organization, product or service consistently functions well. It has four main components: quality planning, quality assurance, quality control and quality improvement. Quality management is focused not only on product and service quality, but also on the means to achieve it. Quality management, therefore, uses quality assurance and control of processes as well as products to achieve more consistent quality. Quality control is also part of quality management. What a customer wants and is willing to pay for it, determines quality. It is a written or unwritten commitment to a known or unknown consumer in the market. Quality can be defined as how well the product performs its intended function.

Reliability engineering is a sub-discipline of systems engineering that emphasizes the ability of equipment to function without failure. Reliability describes the ability of a system or component to function under stated conditions for a specified period of time. Reliability is closely related to availability, which is typically described as the ability of a component or system to function at a specified moment or interval of time.

Quality audit is the process of systematic examination of a quality system carried out by an internal or external quality auditor or an audit team. It is an important part of an organization's quality management system and is a key element in the ISO quality system standard, ISO 9001.

IATF 16949:2016 is a technical specification aimed at the development of a quality management system which provides for continual improvement, emphasizing defect prevention and the reduction of variation and waste in the automotive industry supply chain and assembly process. It is based on the ISO 9001 standard and the first edition was published in June 1999 as ISO/TS 16949:1999. IATF 16949:2016 replaced ISO/TS 16949 in October 2016.

ISO 13485Medical devices -- Quality management systems -- Requirements for regulatory purposes is a voluntary standard, published by International Organization for Standardization (ISO) for the first time in 1996, and contains a comprehensive quality management system for the design and manufacture of medical devices. The latest version of this standard supersedes earlier documents such as EN 46001 and EN 46002 (1996), the previously published ISO 13485, and ISO 13488.

Eight Disciplines Methodology (8D) is a method or model developed at Ford Motor Company used to approach and to resolve problems, typically employed by quality engineers or other professionals. Focused on product and process improvement, its purpose is to identify, correct, and eliminate recurring problems. It establishes a permanent corrective action based on statistical analysis of the problem and on the origin of the problem by determining the root causes. Although it originally comprised eight stages, or 'disciplines', it was later augmented by an initial planning stage. 8D follows the logic of the PDCA cycle. The disciplines are:

A preventive action is a change implemented to address a weakness in a management system that is not yet responsible for causing nonconforming product or service.

Clinical quality management systems (CQMS) are systems used in the life sciences sector designed to manage quality management best practices throughout clinical research and clinical study management. A CQMS system is designed to manage all of the documents, activities, tasks, processes, quality events, relationships, audits and training that must be administered and controlled throughout the life of a clinical trial. The premise of a CQMS is to bring together the activities led by two sectors of clinical research, Clinical Quality and Clinical Operations, to facilitate cross-functional activities to improve efficiencies and transparency and to encourage the use of risk mitigation and risk management practices at the clinical study level.

PTC Windchill is a family of Product Lifecycle Management (PLM) software products that is offered by PTC. In 2004, as part of their expansion in the area of collaboration tools, they arranged having "a hosted version of Windchill to small- and medium-sized customers." As of 2011, products from its marketer, PTC, were being used by over 1.1 million users worldwide.

Continued process verification (CPV) is the collection and analysis of end-to-end production components and processes data to ensure product outputs are within predetermined quality limits. In 2011 the Food and Drug Administration published a report outlining best practices regarding business process validation in the pharmaceutical industry. Continued process verification is outlined in this report as the third stage in Process Validation.

A3 problem solving is a structured problem-solving and continuous-improvement approach, first employed at Toyota and typically used by lean manufacturing practitioners. It provides a simple and strict procedure that guides problem solving by workers. The approach typically uses a single sheet of ISO A3-size paper, which is the source of its name. More contemporary versions include the Systems-oriented A3

Hazard analysis and risk-based preventive controls or HARPC is a successor to the Hazard analysis and critical control points (HACCP) food safety system, mandated in the United States by the FDA Food Safety Modernization Act (FSMA) of 2010.

Avanos Medical, Inc. is a medical technology company making clinical medical devices. The company consists of two franchises – Pain Management and Chronic Care – that address reducing the use of opioids while helping patients recover faster and preventing infection.