A seat belt, also known as a safety belt or spelled seatbelt, is a vehicle safety device designed to secure the driver or a passenger of a vehicle against harmful movement that may result during a collision or a sudden stop. A seat belt reduces the likelihood of death or serious injury in a traffic collision by reducing the force of secondary impacts with interior strike hazards, by keeping occupants positioned correctly for maximum effectiveness of the airbag, and by preventing occupants being ejected from the vehicle in a crash or if the vehicle rolls over.

An airbag is a vehicle occupant-restraint system using a bag designed to inflate exceptionally quickly and then deflate during a collision. It consists of an airbag cushion, a flexible fabric bag, an inflation module, and an impact sensor. The purpose of the airbag is to provide a vehicle occupant with soft cushioning and restraint during a collision. It can reduce injuries between the flailing occupant and the vehicle's interior.

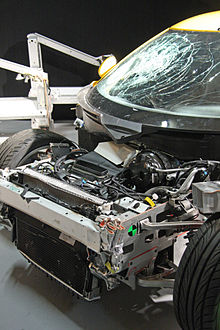

A crash test is a form of destructive testing usually performed in order to ensure safe design standards in crashworthiness and crash compatibility for various modes of transportation or related systems and components.

A rear-end collision, often called rear-ending or, in the UK, a shunt, occurs when a forward-moving vehicle crashes into the back of another vehicle in front of it. Similarly, rear-end rail collisions occur when a train runs into the end of a preceding train on the same track. Common factors contributing to rear-end collisions include driver inattention or distraction, tailgating, panic stops, brake checking and reduced traction due to wet weather or worn pavement.

Automotive safety is the study and practice of automotive design, construction, equipment and regulation to minimize the occurrence and consequences of traffic collisions involving motor vehicles. Road traffic safety more broadly includes roadway design.

Crash incompatibility, crash compatibility, vehicle incompatibility, and vehicle compatibility are terms in the automobile crash testing industry. They refer to the tendency of some vehicles to inflict more damage on another vehicle in two-car crashes. Vehicle incompatibility is said to lead to more dangerous, fatal crashes, while compatibility can prevent injury in otherwise comparable crashes.

A bumper is a structure attached to or integrated with the front and rear ends of a motor vehicle, to absorb impact in a minor collision, ideally minimizing repair costs. Stiff metal bumpers appeared on automobiles as early as 1904 that had a mainly ornamental function. Numerous developments, improvements in materials and technologies, as well as greater focus on functionality for protecting vehicle components and improving safety have changed bumpers over the years. Bumpers ideally minimize height mismatches between vehicles and protect pedestrians from injury. Regulatory measures have been enacted to reduce vehicle repair costs and, more recently, impact on pedestrians.

The European New Car Assessment Programme is a European voluntary car safety performance assessment programme based in Leuven, Belgium. Formed in 1996, the first results were released in February 1997. It was originally started by the Transport Research Laboratory for the UK Department for Transport but later backed by several European governments, as well as by the European Union (EU). Their slogan is "For Safer Cars".

A rollover or overturn is a type of vehicle crash in which a vehicle tips over onto its side or roof. Rollovers have a higher fatality rate than other types of vehicle collisions.

The Volvo VESC, the Volvo Experimental Safety Car, was a concept car made by Volvo to showcase a number of innovative passenger safety features. It was unveiled in 1972 at the Geneva Motor Show.

A side collision is a vehicle crash where the side of one or more vehicles is impacted. These crashes typically occur at intersections, in parking lots, and when two vehicles pass on a multi-lane roadway.

A bullbar or push bumper is a device installed on the front of a vehicle to protect its front from collisions, whether an accidental collision with a large animal in rural roads, or an intentional collision by police with another vehicle. They vary considerably in size and form, and are normally composed of welded steel or aluminium tubing, or, more recently, moulded polycarbonate and polyethylene materials. The "bull" in the name refers to cattle, which in rural areas sometimes roam onto rural roads and highways.

The Mercedes-Benz "Ponton" series is a range of sedans / saloon car models from Daimler-Benz, introduced starting in 1953, and subsequently nicknamed 'Ponton', referring to its ponton styling, a prominent styling trend that unified the previously articulated hood, body, fenders and runnings boards into a singular, often slab-sided envelope. At the time, Mercedes itself did not refer to any of its cars using the nickname.

Béla Barényi was an ethnic Hungarian engineer from Austria-Hungary, who was a prolific inventor, sometimes even compared to Thomas Edison. Barényi made numerous crash protection inventions, and is therefore regarded as the father of passive safety in automotive design.

In May 2013, the World Health Organization (WHO) reported that more than 270,000 pedestrians lose their lives on the world’s roads each year, accounting for 22% of the total 1.24 million road traffic deaths. Despite the magnitude of the problem, most attempts at reducing pedestrian deaths had historically focused solely on education and traffic regulation. Since the 1970s, crash engineers have begun to use design principles that have proved successful in protecting car occupants to develop vehicle design concepts that reduce the likelihood of injuries to pedestrians in the event of a car-pedestrian crash, or reduce the likelihood of a car-pedestrian crash in the first place.

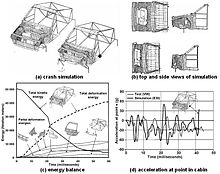

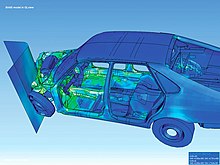

Crashworthiness is the ability of a structure to protect its occupants during an impact. This is commonly tested when investigating the safety of aircraft and vehicles. Different criteria are used to figure out how safe a structure is in a crash, depending on the type of impact and the vehicle involved. Crashworthiness may be assessed either prospectively, using computer models or experiments, or retrospectively, by analyzing crash outcomes. Several criteria are used to assess crashworthiness prospectively, including the deformation patterns of the vehicle structure, the acceleration experienced by the vehicle during an impact, and the probability of injury predicted by human body models. Injury probability is defined using criteria, which are mechanical parameters that correlate with injury risk. A common injury criterion is the head impact criterion (HIC). Crashworthiness is measured after the fact by looking at injury risk in real-world crashes. Often, regression or other statistical methods are used to account for the many other factors that can affect the outcome of a crash.

An impact attenuator, also known as a crash cushion, crash attenuator, or cowboy cushion, is a device intended to reduce the damage to structures, vehicles, and motorists resulting from a motor vehicle collision. Impact attenuators are designed to absorb the colliding vehicle's kinetic energy. They may also be designed to redirect the vehicle away from the hazard or away from roadway machinery and workers. Impact attenuators are usually placed in front of fixed structures near highways, such as gore points, crash barrier introductions, or overpass supports. Temporary versions may be used for road construction projects.

Traffic barriers keep vehicles within their roadway and prevent them from colliding with dangerous obstacles such as boulders, sign supports, trees, bridge abutments, buildings, walls, and large storm drains, or from traversing steep (non-recoverable) slopes or entering deep water. They are also installed within medians of divided highways to prevent errant vehicles from entering the opposing carriageway of traffic and help to reduce head-on collisions. Some of these barriers, designed to be struck from either side, are called median barriers. Traffic barriers can also be used to protect vulnerable areas like school yards, pedestrian zones, and fuel tanks from errant vehicles.

Reinforced Impact Safety Evolution (RISE) or Realized Impact Safety Evolution is the brand name of Mitsubishi's patented safety body construction system. It was first introduced in the 1996 Mitsubishi Galant. Initially designed to improve passive safety, the system has subsequently been developed to electronically integrate every aspect of car's active and passive safety features.

A collision avoidance system (CAS), also known as a pre-crash system, forward collision warning system (FCW), or collision mitigation system, is an advanced driver-assistance system designed to prevent or reduce the severity of a collision. In its basic form, a forward collision warning system monitors a vehicle's speed, the speed of the vehicle in front of it, and the distance between the vehicles, so that it can provide a warning to the driver if the vehicles get too close, potentially helping to avoid a crash. Various technologies and sensors that are used include radar (all-weather) and sometimes laser (LIDAR) and cameras to detect an imminent crash. GPS sensors can detect fixed dangers such as approaching stop signs through a location database. Pedestrian detection can also be a feature of these types of systems.