Ishikawa diagrams are causal diagrams created by Kaoru Ishikawa that show the potential causes of a specific event.

The theory of constraints (TOC) is a management paradigm that views any manageable system as being limited in achieving more of its goals by a very small number of constraints. There is always at least one constraint, and TOC uses a focusing process to identify the constraint and restructure the rest of the organization around it. TOC adopts the common idiom "a chain is no stronger than its weakest link". That means that organizations and processes are vulnerable because the weakest person or part can always damage or break them, or at least adversely affect the outcome.

Lean manufacturing is a production method aimed primarily at reducing times within the production system as well as response times from suppliers and to customers.

Six Sigma (6σ) is a set of techniques and tools for process improvement. It was introduced by American engineer Bill Smith while working at Motorola in 1986. A six sigma process is one in which 99.99966% of all opportunities to produce some feature of a part are statistically expected to be free of defects.

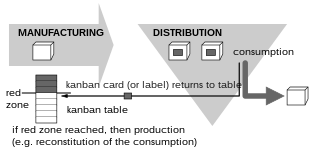

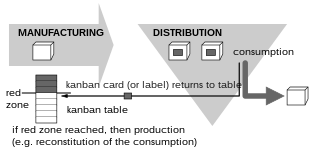

Kanban is a scheduling system for lean manufacturing. Taiichi Ohno, an industrial engineer at Toyota, developed kanban to improve manufacturing efficiency. The system takes its name from the cards that track production within a factory. Kanban is also known as the Toyota nameplate system in the automotive industry.

Statistical process control (SPC) is a method of quality control which employs statistical methods to monitor and control a process. This helps to ensure that the process operates efficiently, producing more specification-conforming products with less waste. SPC can be applied to any process where the "conforming product" output can be measured. Key tools used in SPC include run charts, control charts, a focus on continuous improvement, and the design of experiments. An example of a process where SPC is applied is manufacturing lines.

Operations management is an area of management concerned with designing and controlling the process of production and redesigning business operations in the production of goods or services. It involves the responsibility of ensuring that business operations are efficient in terms of using as few resources as needed and effective in meeting customer requirements.

Safety stock is a term used by logisticians to describe a level of extra stock that is maintained to mitigate risk of stockouts caused by uncertainties in supply and demand. Adequate safety stock levels permit business operations to proceed according to their plans. Safety stock is held when uncertainty exists in demand, supply, or manufacturing yield, and serves as an insurance against stockouts.

Design for manufacturability is the general engineering practice of designing products in such a way that they are easy to manufacture. The concept exists in almost all engineering disciplines, but the implementation differs widely depending on the manufacturing technology. DFM describes the process of designing or engineering a product in order to facilitate the manufacturing process in order to reduce its manufacturing costs. DFM will allow potential problems to be fixed in the design phase which is the least expensive place to address them. Other factors may affect the manufacturability such as the type of raw material, the form of the raw material, dimensional tolerances, and secondary processing such as finishing.

Takt time, or simply Takt, is a manufacturing term to describe the required product assembly duration that is needed to match the demand. Often confused with cycle time, takt time is a tool used to design work and it measures the average time interval between the start of production of one unit and the start of production of the next unit when items are produced sequentially. For calculations, it is the time to produce parts divided by the number of parts demanded in that time interval. The takt time is based on customer demand; if a process or a production line are unable to produce at takt time, either demand leveling, additional resources, or process re-engineering is needed to ensure on-time delivery.

Cellular manufacturing is a process of manufacturing which is a subsection of just-in-time manufacturing and lean manufacturing encompassing group technology. The goal of cellular manufacturing is to move as quickly as possible, make a wide variety of similar products, while making as little waste as possible. Cellular manufacturing involves the use of multiple "cells" in an assembly line fashion. Each of these cells is composed of one or multiple different machines which accomplish a certain task. The product moves from one cell to the next, each station completing part of the manufacturing process. Often the cells are arranged in a "U-shape" design because this allows for the overseer to move less and have the ability to more readily watch over the entire process. One of the biggest advantages of cellular manufacturing is the amount of flexibility that it has. Since most of the machines are automatic, simple changes can be made very rapidly. This allows for a variety of scaling for a product, minor changes to the overall design, and in extreme cases, entirely changing the overall design. These changes, although tedious, can be accomplished extremely quickly and precisely.

Lean construction is a combination of operational research and practical development in design and construction with an adoption of lean manufacturing principles and practices to the end-to-end design and construction process. Unlike manufacturing, construction is a project-based production process. Lean Construction is concerned with the alignment and holistic pursuit of concurrent and continuous improvements in all dimensions of the built and natural environment: design, construction, activation, maintenance, salvaging, and recycling. This approach tries to manage and improve construction processes with minimum cost and maximum value by considering customer needs.

A lean laboratory is one which is focused on processes, procedures, and infrastructure that deliver results in the most efficient way in terms of cost, speed, or both. Lean laboratory is a management and organization process derived from the concept of lean manufacturing and the Toyota Production System (TPS). The goal of a lean laboratory is to reduce resource usage and costs while improving productivity, staff morale, and laboratory-driven outcomes.

Lean Six Sigma is a method that relies on a collaborative team effort to improve performance by systematically removing waste and reducing variation. It combines lean manufacturing/lean enterprise and Six Sigma to eliminate the eight kinds of waste (muda).

Computer-aided lean management, in business management, is a methodology of developing and using software-controlled, lean systems integration. Its goal is to drive innovation towards cost and cycle-time savings. It attempts to create an efficient use of capital and resources through the development and use of one integrated system model to run a business's planning, engineering, design, maintenance, and operations.

Lean dynamics is a business management practice that emphasizes the same primary outcome as lean manufacturing or lean production of eliminating wasteful expenditure of resources. However, it is distinguished by its different focus of creating a structure for accommodating the dynamic business conditions that cause these wastes to accumulate in the first place.

Lean IT is the extension of lean manufacturing and lean services principles to the development and management of information technology (IT) products and services. Its central concern, applied in the context of IT, is the elimination of waste, where waste is work that adds no value to a product or service.

Lean services is the application of lean manufacturing production methods in the service industry. Lean services have among others been applied to US health care providers and the UK HMRC.

Lean integration is a management system that emphasizes creating value for customers, continuous improvement, and eliminating waste as a sustainable data integration and system integration practice. Lean integration has parallels with other lean disciplines such as lean manufacturing, lean IT, and lean software development. It is a specialized collection of tools and techniques that address the unique challenges associated with seamlessly combining information and processes from systems that were independently developed, are based on incompatible data models, and remain independently managed, to achieve a cohesive holistic operation.

Lean product development (LPD) is a lean approach to counter the challenges of product development, notably: