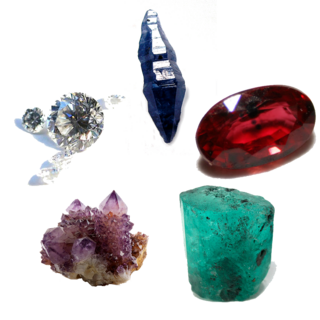

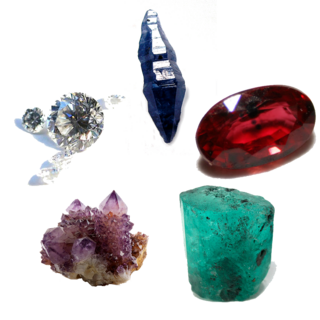

A gemstone is a piece of mineral crystal which, when cut or polished, is used to make jewelry or other adornments. Certain rocks and occasionally organic materials that are not minerals may also be used for jewelry and are therefore often considered to be gemstones as well. Most gemstones are hard, but some softer minerals such as brazilianite may be used in jewelry because of their color or luster or other physical properties that have aesthetic value. However, generally speaking, soft minerals are not typically used as gemstones by virtue of their brittleness and lack of durability.

Lapidary is the practice of shaping stone, minerals, or gemstones into decorative items such as cabochons, engraved gems, and faceted designs. A person who practices lapidary is known as a lapidarist. A lapidarist uses the lapidary techniques of cutting, grinding, and polishing. Hardstone carving requires specialized carving techniques.

The Cullinan Diamond is the largest gem-quality rough diamond ever found, weighing 3,106 carats (621.20 g), discovered at the Premier No.2 mine in Cullinan, South Africa, on 26 January 1905. It was named after Thomas Cullinan, the owner of the mine. In April 1905, it was put on sale in London, but despite considerable interest, it was still unsold after two years. In 1907, the Transvaal Colony government bought the Cullinan and Prime Minister Louis Botha presented it to Edward VII, the British king who reigned over the territory. It was then cut by Joseph Asscher & Co. in Amsterdam.

A cabochon is a gemstone that has been shaped and polished, as opposed to faceted. The resulting form is usually a convex (rounded) obverse with a flat reverse. Cabochon was the default method of preparing gemstones before gemstone cutting developed.

Facets are flat faces on geometric shapes. The organization of naturally occurring facets was key to early developments in crystallography, since they reflect the underlying symmetry of the crystal structure. Gemstones commonly have facets cut into them in order to improve their appearance by allowing them to reflect light.

A brilliant is a diamond or other gemstone cut in a particular form with 57-58 facets so as to have exceptional brilliance. The underside is conical, a shape that provides maximal light return through the top of the diamond. Even with modern techniques, the cutting and polishing of a diamond crystal always results in a dramatic loss of weight; rarely is this loss less than 50%. The round brilliant cut is preferred when the crystal is an octahedron, as often two stones may be cut from one such crystal. Oddly-shaped crystals such as macles are more likely to be cut in a fancy cut—that is, a cut other than the round brilliant—which the particular crystal shape lends itself to.

A diamond cut is a style or design guide used when shaping a diamond for polishing such as the brilliant cut. Cut refers to shape, and also the symmetry, proportioning and polish of a diamond. The cut of a diamond greatly affects a diamond's brilliance—a poorly-cut diamond is less luminous.

A diamond simulant, diamond imitation or imitation diamond is an object or material with gemological characteristics similar to those of a diamond. Simulants are distinct from synthetic diamonds, which are actual diamonds exhibiting the same material properties as natural diamonds. Enhanced diamonds are also excluded from this definition. A diamond simulant may be artificial, natural, or in some cases a combination thereof. While their material properties depart markedly from those of diamond, simulants have certain desired characteristics—such as dispersion and hardness—which lend themselves to imitation. Trained gemologists with appropriate equipment are able to distinguish natural and synthetic diamonds from all diamond simulants, primarily by visual inspection.

The Royal Asscher Diamond Company was founded in 1854 by the Asscher family of gemcutters. The company is responsible for cutting some of the most famous diamonds in the world including the 2nd largest diamond ever found. Its headquarters still stand at its original location Tolstraat 127 in Amsterdam, the Netherlands. The company also has regional headquarters in New York City and Tokyo.

Harry Winston was an American jeweler. He donated the Hope Diamond to the Smithsonian Institution in 1958 after owning it for a decade. He also traded the Portuguese Diamond to the Smithsonian in 1963 in exchange for 3,800 carats of small diamonds.

Diamonds were largely inaccessible to investors until the recent advent of regulated commodities, due to a lack of price discovery and transparency. The characteristics of individual diamonds, especially the carat weight, color and clarity, have significant impact on values, but transactions were always private. With the standardized commodity as an underlying asset, several market traded financial instruments have been announced.

A gemstone desired to be used in jewelry is cut depending on the size and shape of the rough stone, as well as the desired piece of jewelry to be made. As a general rule, a cut gemstone will reduce the mass by about 50%.

The Lesotho Promise, a 603 carat diamond stone of exceptional colour was unearthed on 22 August 2006 at the Letseng diamond mine in the mountain kingdom of Lesotho. Announced on 4 October 2006, it was the largest reported find this century and the 15th largest diamond ever found. The stone is rated 'D', the top colour band for diamonds.

The Tiffany Yellow Diamond is one of the largest yellow diamonds ever discovered. Its carat weight was originally 287.42 carats in the rough when discovered in 1878 in the Kimberley mine in South Africa. It was cut into a cushion shape of 128.54 carats with 82 facets—24 more than a traditional round brilliant—to maximize its brilliance. The facet pattern features eight needle-like facets pointing outward from the culet (bottom) facet. Jewelry and diamond historian Herbert Tillander refers to this as a "stellar brilliant cut", and lists the gem in his book, Diamond Cuts in Historic Jewelry – 1381 to 1910 (1995), among other such diamonds: the Cullinan Diamond, the Koh-i-Noor, the Polar Star, the Wittelsbach, and others.

Gabriel S. Tolkowsky was a Belgian diamond cutter. He was known for cutting the famous Centenary Diamond, and was one of the world's most renowned diamond cutters. The great nephew of Marcel Tolkowsky, father of the modern round brilliant diamond cut, he is the sixth generation in his family to become well-known in the diamond cutting trade.

A faceting machine is broadly defined as any device that allows the user to place and polish facets onto a mineral specimen. Machines can range in sophistication from primitive jamb-peg machines to highly refined, and highly expensive, commercially available machines. A major division among machines is found between those that facet diamonds and those that do not. Specialized equipment is required for diamond faceting, and faceting as an occupation rarely bridges the gap between diamond and non-diamond workmanship. A second division can be made between industrial faceting and custom/hobby faceting. The vast majority of jewelry-store gemstones are faceted either abroad in factories or entirely by machines. Custom jewelry is still commonly made of custom metalwork and mass-produced gemstones, but unusual cuts or particularly valuable gemstone material will likely be faceted on a personal faceting machine.

Diamond is a gemstone formed by cutting a raw diamond. Diamonds are one of the best-known and most sought-after gems, and they have been used as decorative items since ancient times.

Diamond flaws are common. Few natural diamonds are perfect; most of them have inclusions or imperfections. These inclusions are also known as flaws and exist in various forms, such as exterior and interior. Inclusions are also classified in the manner in which they were formed. For example, syngenetic diamond inclusions are inclusions which were formed while a diamond formed, while epigenetic inclusions occurred after a diamond was formed.

The Nassak Diamond is a large, 43.38 carats (8.676 g) Golconda Diamond that originated as a larger 89-carat diamond in the 15th century in India. Found in the Golconda mine of Kollur and originally cut in India, the diamond was the adornment in the Trimbakeshwar Shiva Temple, near Nashik, in the state of Maharashtra, India from at least 1500 to 1817. The British East India Company captured the diamond through the Third Anglo-Maratha War and sold it to British jewellers Rundell and Bridge in 1818. Rundell and Bridge recut the diamond in 1818, after which it made its way into the handle of the 1st Marquess of Westminster's dress sword.

The Wittelsbach-Graff Diamond is a 31.06-carat (6.212 g) deep-blue diamond with internally flawless clarity, originating in the Kollur Mine, India. Laurence Graff purchased the Wittelsbach Diamond in 2008 for £16.4 million. In 2010, Graff revealed he had had the diamond cut by three diamond cutters to remove flaws. The diamond was now more than 4 carats (800 mg) lighter and was renamed the Wittelsbach-Graff Diamond. There is controversy, as critics claim the recutting has so altered the diamond as to make it unrecognisable, compromising its historical integrity.