The Davy lamp is a safety lamp used in flammable atmospheres, invented in 1815 by Sir Humphry Davy. It consists of a wick lamp with the flame enclosed inside a mesh screen. It was created for use in coal mines, to reduce the danger of explosions due to the presence of methane and other flammable gases, called firedamp or minedamp.

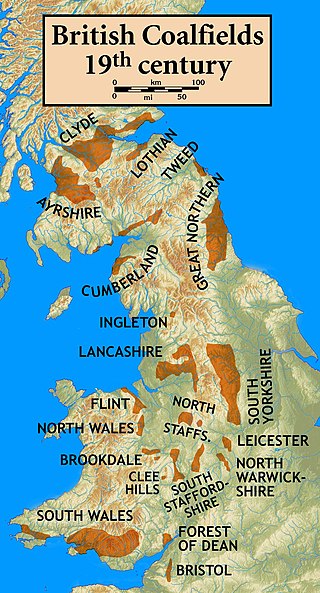

Firedamp is any flammable gas found in coal mines, typically coalbed methane. It is particularly found in areas where the coal is bituminous. The gas accumulates in pockets in the coal and adjacent strata and when they are penetrated the release can trigger explosions. Historically, if such a pocket was highly pressurized, it was termed a "bag of foulness".

The Blantyre mining disaster, which happened on the morning of 22 October 1877, in Blantyre, Scotland, was Scotland's worst ever mining accident. Pits No. 2 and No. 3 of William Dixon's Blantyre Colliery were the site of an explosion which killed 207 miners, possibly more, with the youngest being a boy of 11. It was known that firedamp was present in the pit and it is likely that this was ignited by a naked flame. The accident left 92 widows and 250 fatherless children.

Easington Colliery is a town in County Durham, England, known for a history of coal mining. It is situated to the north of Horden, a short distance to the east of Easington Village. The town suffered a significant mining accident on 29 May 1951, when an explosion in the mine resulted in the deaths of 83 men.

A safety lamp is any of several types of lamp that provides illumination in places such as coal mines where the air may carry coal dust or a build-up of inflammable gases, which may explode if ignited, possibly by an electric spark. Until the development of effective electric lamps in the early 1900s, miners used flame lamps to provide illumination. Open flame lamps could ignite flammable gases which collected in mines, causing explosions; safety lamps were developed to enclose the flame to prevent it from igniting the explosive gases. Flame safety lamps have been replaced for lighting in mining with sealed explosion-proof electric lights, but continue to be used to detect gases.

William Reid Clanny FRSE was an Irish physician and inventor of a safety lamp.

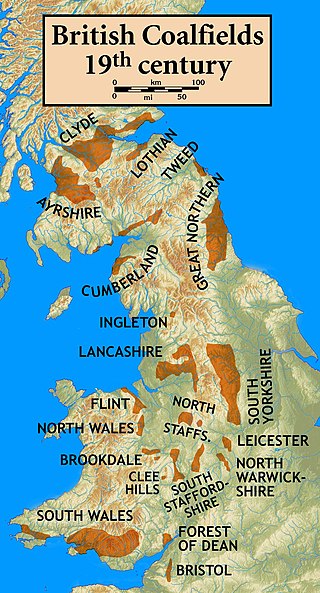

The Senghenydd colliery disaster, also known as the Senghenydd explosion, occurred at the Universal Colliery in Senghenydd, near Caerphilly, Glamorgan, Wales, on 14 October 1913. The explosion, which killed 439 miners and a rescuer, is the worst mining accident in the United Kingdom. Universal Colliery, on the South Wales Coalfield, extracted steam coal, which was much in demand. Some of the region's coal seams contained high quantities of firedamp, a highly explosive gas consisting of methane and hydrogen.

The Oaks explosion, which happened at a coal mine in West Riding of Yorkshire on 12 December 1866, remains the worst mining disaster in England. A series of explosions caused by firedamp ripped through the underground workings at the Oaks Colliery at Hoyle Mill near Stairfoot in Barnsley killing 361 miners and rescuers. It was the worst mining disaster in the United Kingdom until the 1913 Senghenydd explosion in Wales.

The Gresford disaster occurred on 22 September 1934 at Gresford Colliery, near Wrexham, when an explosion and underground fire killed 266 men. Gresford is one of Britain's worst coal mining disasters: a controversial inquiry into the disaster did not conclusively identify a cause, though evidence suggested that failures in safety procedures and poor mine management were contributory factors. Further public controversy was caused by the decision to seal the colliery's damaged sections permanently, meaning that only eleven of those who died were recovered.

Clifton Hall Colliery was one of two coal mines in Clifton on the Manchester Coalfield, historically in Lancashire which was incorporated into the City of Salford in Greater Manchester, England in 1974. Clifton Hall was notorious for an explosion in 1885 which killed around 178 men and boys.

Matthias Dunn was a British mining engineer and one of the first government inspectors of mines. He was known for encouraging safe practices in mines.

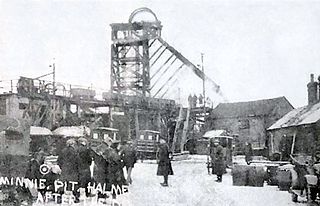

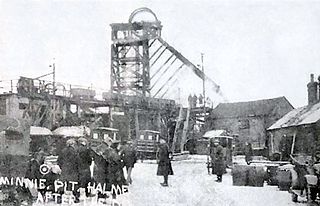

The Minnie Pit disaster was a coal mining accident that took place on 12 January 1918 in Halmer End, Staffordshire, in which 155 men and boys died. The disaster, which was caused by an explosion due to firedamp, is the worst ever recorded in the North Staffordshire Coalfield. An official investigation never established what caused the ignition of flammable gases in the pit.

The West Stanley Pit disasters refers to two explosions at the West Stanley colliery. West Stanley colliery was a coal mine near Stanley, with the mine opening in 1832 and closing in 1936. Over the years several seams were worked through four shafts: Kettledrum pit, Lamp pit, Mary pit and New pit. In 1882 an underground explosion killed 13 men and in 1909 another explosion killed 168 men.

Six Bells Colliery was a colliery located in Six Bells, Abertillery, Gwent, Wales. On 28 June 1960 it was the site of an underground explosion which killed 45 of the 48 miners working in that part of the mine. It is now the site of the artistically acclaimed Guardian memorial to those events, designed by Sebastian Boyesen; although the memorial primarily commemorates those who died at Six Bells, it is dedicated to all mining communities wherever they may be.

The Bedford Colliery disaster occurred on Friday 13 August 1886 when an explosion of firedamp caused the death of 38 miners at Bedford No.2 Pit, at Bedford, Leigh in what then was Lancashire. The colliery, sunk in 1884 and known to be a "fiery pit", was owned by John Speakman.

Sheriff Hill Colliery or Ellison Main Colliery was a coal mine at Gateshead Fell in County Durham, England. The colliery had two shafts and provided employment to the residents of Sheriff Hill, after it opened in 1793. There were many major accidents resulting in the deaths of workers at the colliery. There was a protracted strike at the colliery in 1834. The colliery closed in 1926.

John Hodgson (1779–1845) was an English clergyman and antiquary, known as the county historian of Northumberland.

The Abercarn colliery disaster was a catastrophic explosion within the Prince of Wales Colliery in the Welsh village of Abercarn, on 11 September 1878, killing 268 men and boys. The cause was assumed to have been the ignition of firedamp by a safety lamp. The disaster is the third worst for loss of life to occur within the South Wales Coalfield.

This is a partial glossary of coal mining terminology commonly used in the coalfields of the United Kingdom. Some words were in use throughout the coalfields, some are historic and some are local to the different British coalfields.

The Lundhill Colliery explosion was a coal mining accident which took place on 19 February 1857 in Wombwell, Yorkshire, UK in which 189 men and boys aged between 10 and 59 died. It is one of the biggest industrial disasters in the country's history and it was caused by a firedamp explosion. It was the first disaster to appear on the front page of the Illustrated London News.