Corundum is a crystalline form of aluminium oxide typically containing traces of iron, titanium, vanadium and chromium. It is a rock-forming mineral. It is a naturally transparent material, but can have different colors depending on the presence of transition metal impurities in its crystalline structure. Corundum has two primary gem varieties: ruby and sapphire. Rubies are red due to the presence of chromium, and sapphires exhibit a range of colors depending on what transition metal is present. A rare type of sapphire, padparadscha sapphire, is pink-orange.

Sapphire is a precious gemstone, a variety of the mineral corundum, consisting of aluminium oxide (α-Al2O3) with trace amounts of elements such as iron, titanium, chromium, vanadium, or magnesium. The name sapphire is derived via the Latin "sapphirus" from the Greek "sappheiros", which referred to lapis lazuli. It is typically blue, but natural "fancy" sapphires also occur in yellow, purple, orange, and green colors; "parti sapphires" show two or more colors. Red corundum stones also occur, but are called rubies rather than sapphires. Pink-colored corundum may be classified either as ruby or sapphire depending on locale. Commonly, natural sapphires are cut and polished into gemstones and worn in jewelry. They also may be created synthetically in laboratories for industrial or decorative purposes in large crystal boules. Because of the remarkable hardness of sapphires – 9 on the Mohs scale (the third hardest mineral, after diamond at 10 and moissanite at 9.5) – sapphires are also used in some non-ornamental applications, such as infrared optical components, high-durability windows, wristwatch crystals and movement bearings, and very thin electronic wafers, which are used as the insulating substrates of special-purpose solid-state electronics such as integrated circuits and GaN-based blue LEDs. Sapphire is the birthstone for September and the gem of the 45th anniversary. A sapphire jubilee occurs after 65 years.

A watch is a portable timepiece intended to be carried or worn by a person. It is designed to keep a consistent movement despite the motions caused by the person's activities. A wristwatch is designed to be worn around the wrist, attached by a watch strap or other type of bracelet, including metal bands, leather straps or any other kind of bracelet. A pocket watch is designed for a person to carry in a pocket, often attached to a chain.

A ball bearing is a type of rolling-element bearing that uses balls to maintain the separation between the bearing races.

Fluid bearings are bearings in which the load is supported by a thin layer of rapidly moving pressurized liquid or gas between the bearing surfaces. Since there is no contact between the moving parts, there is no sliding friction, allowing fluid bearings to have lower friction, wear and vibration than many other types of bearings. Thus, it is possible for some fluid bearings to have near-zero wear if operated correctly.

A bearing is a machine element that constrains relative motion to only the desired motion, and reduces friction between moving parts. The design of the bearing may, for example, provide for free linear movement of the moving part or for free rotation around a fixed axis; or, it may prevent a motion by controlling the vectors of normal forces that bear on the moving parts. Most bearings facilitate the desired motion by minimizing friction. Bearings are classified broadly according to the type of operation, the motions allowed, or to the directions of the loads (forces) applied to the parts.

The year 1704 in science and technology involved some significant events.

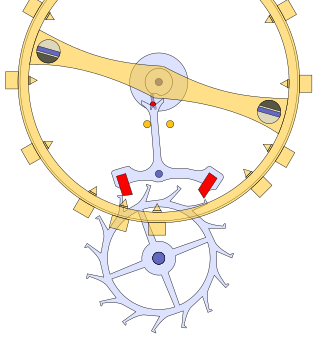

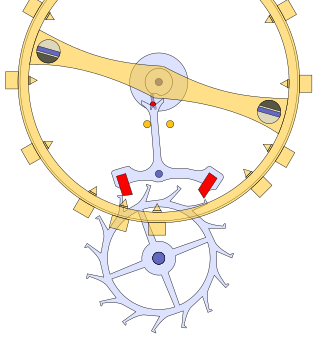

The grasshopper escapement is a low-friction escapement for pendulum clocks invented by British clockmaker John Harrison around 1722. An escapement, part of every mechanical clock, is the mechanism that gives the clock's pendulum periodic pushes to keep it swinging, and each swing releases the clock's gears to move forward by a fixed amount, thus moving the hands forward at a steady rate. The grasshopper escapement was used in a few regulator clocks built during Harrison's time, and a few others over the years, but has never seen wide use. The term "grasshopper" in this connection, apparently from the kicking action of the pallets, first appears in the Horological Journal in the late 19th century.

An escapement is a mechanical linkage in mechanical watches and clocks that gives impulses to the timekeeping element and periodically releases the gear train to move forward, advancing the clock's hands. The impulse action transfers energy to the clock's timekeeping element to replace the energy lost to friction during its cycle and keep the timekeeper oscillating. The escapement is driven by force from a coiled spring or a suspended weight, transmitted through the timepiece's gear train. Each swing of the pendulum or balance wheel releases a tooth of the escapement's escape wheel, allowing the clock's gear train to advance or "escape" by a fixed amount. This regular periodic advancement moves the clock's hands forward at a steady rate. At the same time, the tooth gives the timekeeping element a push, before another tooth catches on the escapement's pallet, returning the escapement to its "locked" state. The sudden stopping of the escapement's tooth is what generates the characteristic "ticking" sound heard in operating mechanical clocks and watches.

A plain bearing, or more commonly sliding contact bearing and slide bearing, is the simplest type of bearing, comprising just a bearing surface and no rolling elements. Therefore, the journal slides over the bearing surface. The simplest example of a plain bearing is a shaft rotating in a hole. A simple linear bearing can be a pair of flat surfaces designed to allow motion; e.g., a drawer and the slides it rests on or the ways on the bed of a lathe.

A flexure bearing is a category of flexure which is engineered to be compliant in one or more angular degrees of freedom. Flexure bearings are often part of compliant mechanisms. Flexure bearings serve much of the same function as conventional bearings or hinges in applications which require angular compliance. However, flexures require no lubrication and exhibit very low or no friction.

In mechanical engineering, a rolling-element bearing, also known as a rolling bearing, is a bearing which carries a load by placing rolling elements between two concentric, grooved rings called races. The relative motion of the races causes the rolling elements to roll with very little rolling resistance and with little sliding.

In horology, a tourbillon is an addition to the mechanics of a watch escapement to increase accuracy. It was developed around 1795 and patented by the Swiss-French watchmaker Abraham-Louis Breguet on June 26, 1801. In a tourbillon the escapement and balance wheel are mounted in a rotating cage, with the goal of eliminating errors of poise in the balance giving a uniform weight.

The lever escapement, invented by the English clockmaker Thomas Mudge in 1754, is a type of escapement that is used in almost all mechanical watches, as well as small mechanical non-pendulum clocks, alarm clocks, and kitchen timers.

A Roskopf, pin-lever, or pin-pallet escapement is an inexpensive, less accurate version of the lever escapement, used in mechanical alarm clocks, kitchen timers, mantel clocks and, until the 1970s, cheap watches now known as pin lever watches. It was popularized by German watchmaker Georges Frederic Roskopf in it "proletarian watch" from 1867. It was invented by Louis Perron, of Besançon, suggested to Roskopf by Jules Grossmann.

A mechanical watch is a watch that uses a clockwork mechanism to measure the passage of time, as opposed to quartz watches which function using the vibration modes of a piezoelectric quartz tuning fork, or radio watches, which are quartz watches synchronized to an atomic clock via radio waves. A mechanical watch is driven by a mainspring which must be wound either periodically by hand or via a self-winding mechanism. Its force is transmitted through a series of gears to power the balance wheel, a weighted wheel which oscillates back and forth at a constant rate. A device called an escapement releases the watch's wheels to move forward a small amount with each swing of the balance wheel, moving the watch's hands forward at a constant rate. The escapement is what makes the 'ticking' sound which is heard in an operating mechanical watch. Mechanical watches evolved in Europe in the 17th century from spring powered clocks, which appeared in the 15th century.

A marine chronometer is a precision timepiece that is carried on a ship and employed in the determination of the ship's position by celestial navigation. It is used to determine longitude by comparing Greenwich Mean Time (GMT), or in the modern world its successor Coordinated Universal Time (UTC), and the time at the current location found from observations of celestial bodies. When first developed in the 18th century, it was a major technical achievement, as accurate knowledge of the time over a long sea voyage was vital for effective navigation, lacking electronic or communications aids. The first true chronometer was the life work of one man, John Harrison, spanning 31 years of persistent experimentation and testing that revolutionized naval navigation and enabling the Age of Discovery and Colonialism to accelerate.

A chronometer is an extraordinarily accurate timepiece, with an original focus on the needs of maritime navigation. In Switzerland, timepieces certified by the Contrôle Officiel Suisse des Chronomètres (COSC) may be marked as Certified Chronometer or Officially Certified Chronometer. Outside Switzerland, equivalent bodies, such as the Japan Chronometer Inspection Institute, have in the past certified timepieces to similar standards, although use of the term has not always been strictly controlled.

Dry lubricants or solid lubricants are materials that, despite being in the solid phase, are able to reduce friction between two surfaces sliding against each other without the need for a liquid oil medium.

A PIGA is a type of accelerometer that can measure acceleration and simultaneously integrates this acceleration against time to produce a speed measure as well. The PIGA's main use is in Inertial Navigation Systems (INS) for guidance of aircraft and most particularly for ballistic missile guidance. It is valued for its extremely high sensitivity and accuracy in conjunction with operation over a wide acceleration range. The PIGA is still considered the premier instrument for strategic grade missile guidance, though systems based on MEMS technology are attractive for lower performance requirements.