A physics engine is computer software that provides an approximate simulation of certain physical systems, such as rigid body dynamics, soft body dynamics, and fluid dynamics, of use in the domains of computer graphics, video games and film (CGI). Their main uses are in video games, in which case the simulations are in real-time. The term is sometimes used more generally to describe any software system for simulating physical phenomena, such as high-performance scientific simulation.

Ansys, Inc. is an American multinational company with its headquarters based in Canonsburg, Pennsylvania. It develops and markets CAE/multiphysics engineering simulation software for product design, testing and operation and offers its products and services to customers worldwide.

A crash simulation is a virtual recreation of a destructive crash test of a car or a highway guard rail system using a computer simulation in order to examine the level of safety of the car and its occupants. Crash simulations are used by automakers during computer-aided engineering (CAE) analysis for crashworthiness in the computer-aided design (CAD) process of modelling new cars. During a crash simulation, the kinetic energy, or energy of motion, that a vehicle has before the impact is transformed into deformation energy, mostly by plastic deformation (plasticity) of the car body material, at the end of the impact.

Dassault Systèmes Simulia Corp. is a computer-aided engineering (CAE) vendor. Formerly known as Abaqus Inc. and previously Hibbitt, Karlsson & Sorensen, Inc., (HKS), the company was founded in 1978 by David Hibbitt, Bengt Karlsson and Paul Sorensen, and has its headquarters in Providence, Rhode Island.

Tecplot is the name of a family of visualization & analysis software tools developed by American company Tecplot, Inc., which is headquartered in Bellevue, Washington. The firm was formerly operated as Amtec Engineering. In 2016, the firm was acquired by Vela Software, an operating group of Constellation Software, Inc. (TSX:CSU).

Soft-body dynamics is a field of computer graphics that focuses on visually realistic physical simulations of the motion and properties of deformable objects. The applications are mostly in video games and films. Unlike in simulation of rigid bodies, the shape of soft bodies can change, meaning that the relative distance of two points on the object is not fixed. While the relative distances of points are not fixed, the body is expected to retain its shape to some degree. The scope of soft body dynamics is quite broad, including simulation of soft organic materials such as muscle, fat, hair and vegetation, as well as other deformable materials such as clothing and fabric. Generally, these methods only provide visually plausible emulations rather than accurate scientific/engineering simulations, though there is some crossover with scientific methods, particularly in the case of finite element simulations. Several physics engines currently provide software for soft-body simulation.

Autodesk Simulation is a general-purpose multiphysics finite element analysis software package initially developed by ALGOR Incorporated and acquired by Autodesk in January 2009. It is intended for use with Microsoft Windows and Linux operating systems. It is distributed in a number of different core packages to cater to specific applications, such as mechanical event simulation and computational fluid dynamics.

RealFlow is a fluid and dynamics simulation tool for the 3D and visual effects industry, developed by Next Limit Technologies in Madrid, Spain. This stand-alone application can be used in conjunction with other 3D programs to simulate fluids, water surfaces, fluid-solid interactions, rigid bodies, soft bodies and meshes. In 2008, Next Limit Technologies was awarded a Technical Achievement Award by the Academy of Motion Picture Arts and Sciences for their development of the RealFlow software and its contribution to the production of motion pictures. In 2015, Next Limit Technologies announced the release of RealFlow Core for Cinema 4D.

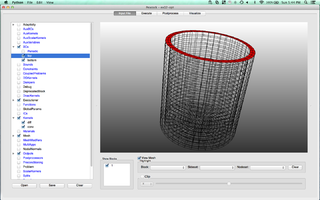

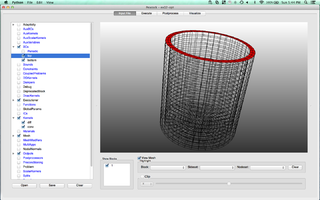

Femap is an engineering analysis program sold by Siemens Digital Industries Software that is used to build finite element models of complex engineering problems ("pre-processing") and view solution results ("post-processing"). It runs on Microsoft Windows and provides CAD import, modeling and meshing tools to create a finite element model, as well as postprocessing functionality that allows mechanical engineers to interpret analysis results. The finite element method allows engineers to virtually model components, assemblies, or systems to determine behavior under a given set of boundary conditions, and is typically used in the design process to reduce costly prototyping and testing, evaluate differing designs and materials, and for structural optimization to reduce weight.

NESSUS is a general-purpose, probabilistic analysis program that simulates variations and uncertainties in loads, geometry, material behavior and other user-defined inputs to compute probability of failure and probabilistic sensitivity measures of engineered systems. Because NESSUS uses highly efficient and accurate probabilistic analysis methods, probabilistic solutions can be obtained even for extremely large and complex models. The system performance can be hierarchically decomposed into multiple smaller models and/or analytical equations. Once the probabilistic response is quantified, the results can be used to support risk-informed decisions regarding reliability for safety critical and one-of-a-kind systems, and to maintain a level of quality while reducing manufacturing costs for larger quantity products.

Z88 is a software package for the finite element method (FEM) and topology optimization. A team led by Frank Rieg at the University of Bayreuth started development in 1985 and now the software is used by several universities, as well as small and medium-sized enterprises. Z88 is capable of calculating two and three dimensional element types with a linear approach. The software package contains several solvers and two post-processors and is available for Microsoft Windows, Mac OS X and Unix/Linux computers in 32-bit and 64-bit versions. Benchmark tests conducted in 2007 showed a performance on par with commercial software.

Synopsys Simpleware ScanIP is a 3D image processing and model generation software program developed by Synopsys Inc. to visualise, analyse, quantify, segment and export 3D image data from magnetic resonance imaging (MRI), computed tomography (CT), microtomography and other modalities for computer-aided design (CAD), finite element analysis (FEA), computational fluid dynamics (CFD), and 3D printing. The software is used in the life sciences, materials science, nondestructive testing, reverse engineering and petrophysics.

FEBio(Finite Elements for Biomechanics) is a software package for finite element analysis and was specifically designed for applications in biomechanics and bioengineering. It was developed in collaboration with research groups from the University of Utah and Columbia University (MBL).

Pam-Crash is a software package from ESI Group used for crash simulation and the design of occupant safety systems, primarily in the automotive industry. The software enables automotive engineers to simulate the performance of a proposed vehicle design and evaluate the potential for injury to occupants in multiple crash scenarios.

VisualFEA is a finite element analysis software program for Microsoft Windows and Mac OS X. It is developed and distributed by Intuition Software, Inc. of South Korea, and used chiefly for structural and geotechnical analysis. Its strongest point is its intuitive, user-friendly design based on graphical pre- and postprocessing capabilities. It has educational features for teaching and learning structural mechanics, and finite element analysis through graphical simulation. It is widely used in college-level courses related to structural mechanics and finite element methods.

Reaction Design is a San Diego-based developer of combustion simulation software used by engineers to design cleaner burning and fuel-efficient combustors and engines, found in everything from automobiles to turbines for power generation and aircraft propulsion to large diesel engines that use pistons the size of rooms to propel ships locomotives. The technology is also used to model spray vaporization in electronic materials processing applications and predict mixing reactions in chemical plants. Ansys, a leader in engineering simulation software, acquired Reaction Design in January 2014.

SmartDO is a multidisciplinary design optimization software, based on the Direct Global Search technology developed and marketed by FEA-Opt Technology. SmartDO specialized in the CAE-Based optimization, such as CAE, FEA, CAD, CFD and automatic control, with application on various physics phenomena. It is both GUI and scripting driven, allowed to be integrated with almost any kind of CAD/CAE and in-house codes.

MOOSE is an object-oriented C++ finite element framework for the development of tightly coupled multiphysics solvers from Idaho National Laboratory. MOOSE makes use of the PETSc non-linear solver package and libmesh to provide the finite element discretization.

Goma is an open-source, parallel, and scalable multiphysics software package for modeling and simulation of real-life physical processes, with a basis in computational fluid dynamics for problems with evolving geometry. It solves problems in all branches of mechanics, including fluids, solids, and thermal analysis. Goma uses advanced numerical methods, focusing on the low-speed flow regime with coupled phenomena for manufacturing and performance applications. It also provides a flexible software development environment for specialty physics.