Related Research Articles

Eli Whitney Jr. was an American inventor, widely known for inventing the cotton gin in 1793, one of the key inventions of the Industrial Revolution that shaped the economy of the Antebellum South.

Mass production, also known as flow production or continuous production, is the production of substantial amounts of standardized products in a constant flow, including and especially on assembly lines. Together with job production and batch production, it is one of the three main production methods.

The American system of manufacturing was a set of manufacturing methods that evolved in the 19th century. The two notable features were the extensive use of interchangeable parts and mechanization for production, which resulted in more efficient use of labor compared to hand methods. The system was also known as armory practice because it was first fully developed in armories, namely, the United States Armories at Springfield in Massachusetts and Harpers Ferry in Virginia, inside contractors to supply the United States Armed Forces, and various private armories. The name "American system" came not from any aspect of the system that is unique to the American national character, but simply from the fact that for a time in the 19th century it was strongly associated with the American companies who first successfully implemented it, and how their methods contrasted with those of British and continental European companies. In the 1850s, the "American system" was contrasted to the British factory system which had evolved over the previous century. Within a few decades, manufacturing technology had evolved further, and the ideas behind the "American" system were in use worldwide. Therefore, in manufacturing today, which is global in the scope of its methods, there is no longer any such distinction.

Fordism is an industrial engineering and manufacturing system that serves as the basis of modern social and labor-economic systems that support industrialized, standardized mass production and mass consumption. The concept is named after Henry Ford. It is used in social, economic, and management theory about production, working conditions, consumption, and related phenomena, especially regarding the 20th century. It describes an ideology of advanced capitalism centered around the American socioeconomic systems in place in the post-war economic boom.

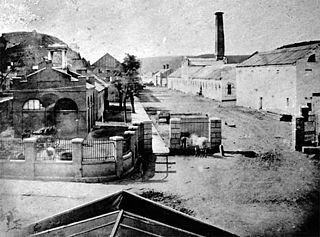

The Springfield Armory, more formally known as the United States Armory and Arsenal at Springfield located in the city of Springfield, Massachusetts, was the primary center for the manufacture of United States military firearms from 1777 until its closing in 1968. It was the first federal armory and one of the first factories in the United States dedicated to the manufacture of weapons. The site is preserved as the Springfield Armory National Historic Site, Western Massachusetts' only unit of the national park system. It features the world's largest collection of historic American firearms.

Interchangeable parts are parts that are identical for practical purposes. They are made to specifications that ensure that they are so nearly identical that they will fit into any assembly of the same type. One such part can freely replace another, without any custom fitting, such as filing. This interchangeability allows easy assembly of new devices, and easier repair of existing devices, while minimizing both the time and skill required of the person doing the assembly or repair.

The factory system is a method of manufacturing using machinery and division of labor. Because of the high capital cost of machinery and factory buildings, factories are typically privately owned by wealthy individuals or corporations who employ the operative labor. Use of machinery with the division of labor reduced the required skill-level of workers and also increased the output per worker.

Thomas Blanchard was an American inventor who lived much of his life in Springfield, Massachusetts, where in 1819, he pioneered the assembly line style of mass production in America, and also invented the first machining lathe for interchangeable parts. Blanchard worked, for much of his career, with the Springfield Armory. In 1825, Blanchard also invented America's first car, which he called a "horseless carriage," powered by steam. During Blanchard's lifetime, he was awarded over twenty-five patents for his creations.

John Hancock Hall was the inventor of the M1819 Hall breech-loading rifle and a mass production innovator.

The American Precision Museum is located in the renovated 1846 Robbins & Lawrence factory on South Main Street in Windsor, Vermont. The building is said to be the first U.S. factory at which precision interchangeable parts were made, giving birth to the precision machine tool industry. In recognition of this history, the building was declared a National Historic Landmark in 1966. In 1987, the building was recognized by the American Society of Mechanical Engineers as an International Heritage Site, and the collection was recognized as an International Heritage Collection. For each of these designations, the armory was considered a site where pivotal events occurred in the history of American industry, as well as a place that lends itself to comprehensive interpretation of that history.

Louis de Tousard (1749-1817) was a French artillerist who served in the American Continental Army under La Fayette, and later was given a US commission. Tousard wrote two very influential books: one was a proposal for a school for officers that became the blueprint for West Point, and the other was a manual for artillery officers that became standard in the young army.

The Harpers Ferry Armory, more formally known as the United States Armory and Arsenal at Harpers Ferry, was the second federal armory created by the United States government; the first was the Springfield Armory. It was located in Harpers Ferry, Virginia, which since 1863 has been part of West Virginia. It was both an arsenal, manufacturing firearms, and an armory, a storehouse for firearms. Along with the Springfield Armory, it was instrumental in the development of machining techniques to make interchangeable parts of precisely the same dimensions.

Honoré Blanc (1736–1801) was a French gunsmith and a pioneer of the use of interchangeable parts. He was born in Avignon in 1736 and apprenticed to the gun-making trade at the age of twelve. His career spanned the decades from circa 1750 to 1801, a time period that included the reigns of Louis XV and Louis XVI, the American Revolution, the French Revolution, and the French First Republic.

James H. Burton was born in Shenandoah Spring, Virginia. Educated at the Westchester Academy in Pennsylvania, Burton entered a Baltimore machine shop at age 16. In April 1844, he went to work at the Harpers Ferry Armory, serving as a machinist. He subsequently served as Foreman of the Rifle Factory Machine Shop, where he gained a considerable amount of knowledge and respect for the work of John H. Hall. Hall pioneered mechanized arms production and interchangeable manufacture at Harpers Ferry between 1820-1840. According to Burton, Hall's Rifle Works housed "not an occasional machine, but a plant of milling machinery by which the system and economy of the manufacture was materially altered." During the next three decades, Burton followed Hall's example by furthering the mechanization of arms production.

David Allen Hounshell is an American academic. He is the David M. Roderick Professor of Technology and Social Change in the Department of Social and Decision Sciences, Department of History, and the Department of Engineering and Public Policy at Carnegie Mellon University. He is known for his work of the history of research and development and industrial research in the United States, particularly at DuPont.

The Springfield Model 1835 was a .69 caliber flintlock musket manufactured in the United States during the early 19th century.

A machine tool builder is a corporation or person that builds machine tools, usually for sale to manufacturers, who use them to manufacture products. A machine tool builder runs a machine factory, which is part of the machine industry.

Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a workpiece. This may be done by varying directions on one or several axes, cutter head speed, and pressure. Milling covers a wide variety of different operations and machines, on scales from small individual parts to large, heavy-duty gang milling operations. It is one of the most commonly used processes for machining custom parts to precise tolerances.

Technological determinism is a reductionist theory that assumes that a society's technology progresses by following its own internal logic of efficiency, while determining the development of the social structure and cultural values. The term is believed to have originated from Thorstein Veblen (1857–1929), an American sociologist and economist. The most radical technological determinist in the United States in the 20th century was most likely Clarence Ayres who was a follower of Thorstein Veblen and John Dewey. William Ogburn was also known for his radical technological determinism and his theory on cultural lag.

The copying lathe or duplicating lathe is a lathe that creates shapes identical to the specified pattern.