Computer-aided manufacturing (CAM) also known as computer-aided modeling or computer-aided machining is the use of software to control machine tools in the manufacturing of work pieces. This is not the only definition for CAM, but it is the most common. It may also refer to the use of a computer to assist in all operations of a manufacturing plant, including planning, management, transportation and storage. Its primary purpose is to create a faster production process and components and tooling with more precise dimensions and material consistency, which in some cases, uses only the required amount of raw material, while simultaneously reducing energy consumption. CAM is now a system used in schools and lower educational purposes. CAM is a subsequent computer-aided process after computer-aided design (CAD) and sometimes computer-aided engineering (CAE), as the model generated in CAD and verified in CAE can be input into CAM software, which then controls the machine tool. CAM is used in many schools alongside CAD to create objects.

A machine tool is a machine for handling or machining metal or other rigid materials, usually by cutting, boring, grinding, shearing, or other forms of deformations. Machine tools employ some sort of tool that does the cutting or shaping. All machine tools have some means of constraining the workpiece and provide a guided movement of the parts of the machine. Thus, the relative movement between the workpiece and the cutting tool is controlled or constrained by the machine to at least some extent, rather than being entirely "offhand" or "freehand". It is a power-driven metal cutting machine which assists in managing the needed relative motion between cutting tool and the job that changes the size and shape of the job material.

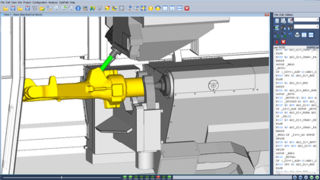

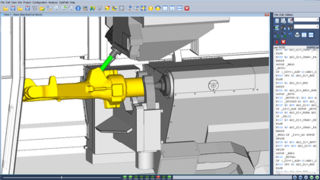

Mastercam is a suite of computer-aided manufacturing (CAM) and CAD/CAM software applications developed by CNC Software, LLC. Founded in Massachusetts in 1983, CNC Software are headquartered in Tolland, Connecticut.

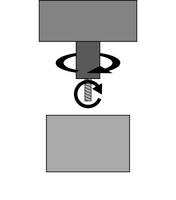

In machining, a shaper is a type of machine tool that uses linear relative motion between the workpiece and a single-point cutting tool to machine a linear toolpath. Its cut is analogous to that of a lathe, except that it is (archetypally) linear instead of helical.

In machining, numerical control, also called computer numerical control (CNC), is the automated control of tools by means of a computer. It is used to operate tools such as drills, lathes, mills, grinders, routers and 3D printers. CNC transforms a piece of material into a specified shape by following coded programmed instructions and without a manual operator directly controlling the machining operation.

G-code is the most widely used computer numerical control (CNC) and 3D printing programming language. It is used mainly in computer-aided manufacturing to control automated machine tools, as well as for 3D-printer slicer applications. The G stands for geometry. G-code has many variants.

Tebis is a CAD/CAM software provided by Tebis AG, with headquarters in Martinsried near Munich/Germany. Development locations: Martinsried and Norderstedt, Germany International locations: China, Spain, France, Italy, Portugal, Sweden, United Kingdom, USA.

A Tool and Cutter Grinder is used to sharpen milling cutters and tool bits along with a host of other cutting tools.

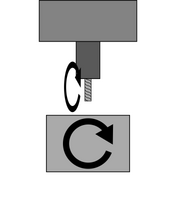

Turning is a machining process in which a cutting tool, typically a non-rotary tool bit, describes a helix toolpath by moving more or less linearly while the workpiece rotates.

In machining, a metal lathe or metalworking lathe is a large class of lathes designed for precisely machining relatively hard materials. They were originally designed to machine metals; however, with the advent of plastics and other materials, and with their inherent versatility, they are used in a wide range of applications, and a broad range of materials. In machining jargon, where the larger context is already understood, they are usually simply called lathes, or else referred to by more-specific subtype names. These rigid machine tools remove material from a rotating workpiece via the movements of various cutting tools, such as tool bits and drill bits.

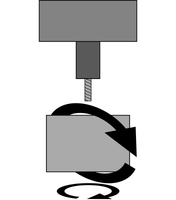

A rotary table is a precision work positioning device used in metalworking. It enables the operator to drill or cut work at exact intervals around a fixed axis. Some rotary tables allow the use of index plates for indexing operations, and some can also be fitted with dividing plates that enable regular work positioning at divisions for which indexing plates are not available. A rotary fixture used in this fashion is more appropriately called a dividing head.

STEP-NC is a machine tool control language that extends the ISO 10303 STEP standards with the machining model in ISO 14649, adding geometric dimension and tolerance data for inspection, and the STEP PDM model for integration into the wider enterprise. The combined result has been standardized as ISO 10303-238.

A computer numerical control (CNC) router is a computer-controlled cutting machine which typically mounts a hand-held router as a spindle which is used for cutting various materials, such as wood, composites, metals, plastics, glass, and foams. CNC routers can perform the tasks of many carpentry shop machines such as the panel saw, the spindle moulder, and the boring machine. They can also cut joinery such as mortises and tenons.

WorkNC is a Computer aided manufacturing (CAM) software developed by Sescoi for multi-axis machining.

In metalworking and woodworking, an automatic lathe is a lathe with an automatically controlled cutting process. Automatic lathes were first developed in the 1870s and were mechanically controlled. From the advent of NC and CNC in the 1950s, the term automatic lathe has generally been used for only mechanically controlled lathes, although some manufacturers market Swiss-type CNC lathes as 'automatic'.

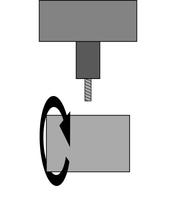

Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a workpiece. This may be done by varying directions on one or several axes, cutter head speed, and pressure. Milling covers a wide variety of different operations and machines, on scales from small individual parts to large, heavy-duty gang milling operations. It is one of the most commonly used processes for machining custom parts to precise tolerances.

Vericut, is a software program used for simulating CNC machining. It is used to simulate tool motion and the material removal process, detecting errors or areas of inefficiency in NC programs. It was developed by CGTech Inc. and first released in 1988.

In manufacturing, freeform surface machining refers to the machining of complex surfaces that are not uniformly planar. The industries which most often manufactures free-form surfaces are basically aerospace, automotive, die mold industries, biomedical and power sector for turbine blades manufacturing. Generally 3- or 5-axis CNC milling machines are used for this purpose. The manufacturing process of freeform surfaces is not an easy job, as the tool path generation in present CAM technology is generally based on geometric computation so tool path are not optimum. The geometry can also be not described explicitly so errors and discontinuities occurrence in the solid structure cannot be avoided. Free-form surfaces are machined with the help of different tool path generation method like adaptive iso-planar tool path generation, constant scallop tool path generation, adaptive iso-parametric method, iso-curvature, isophote and by other methods. The different methods are chosen based on the parameters which is needed to be optimized.

NCSIMUL is a software program developed by the company SPRING Technologies, that is used for simulating, verifying, and optimizing CNC machining in a 3-step process. It reads the post-processed G-code to identify the tool path, and replicates the material removal process of the machine by cutting volumes. It then identifies all syntax errors in the code, crashes in the machining environment, and deviations from the modeled CAD part.