A forge is a type of hearth used for heating metals, or the workplace (smithy) where such a hearth is located. The forge is used by the smith to heat a piece of metal to a temperature at which it becomes easier to shape by forging, or to the point at which work hardening no longer occurs. The metal is transported to and from the forge using tongs, which are also used to hold the workpiece on the smithy's anvil while the smith works it with a hammer. Sometimes, such as when hardening steel or cooling the work so that it may be handled with bare hands, the workpiece is transported to the slack tub, which rapidly cools the workpiece in a large body of water. However, depending on the metal type, it may require an oil quench or a salt brine instead; many metals require more than plain water hardening. The slack tub also provides water to control the fire in the forge.

For postage stamps, separation is the means by which individual stamps are made easily detachable from each other.

Metalworking is the process of shaping and reshaping metals to create useful objects, parts, assemblies, and large scale structures. As a term it covers a wide and diverse range of processes, skills, and tools for producing objects on every scale: from huge ships, buildings, and bridges down to precise engine parts and delicate jewelry.

A die is a specialized machine tool used in manufacturing industries to cut and/or form material to a desired shape or profile. Stamping dies are used with a press, as opposed to drawing dies and casting dies which are not. Like molds, dies are generally customized to the item they are used to create.

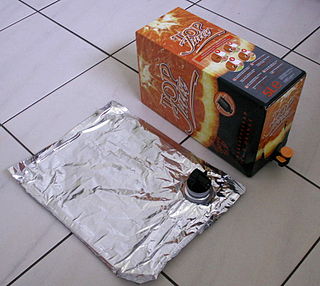

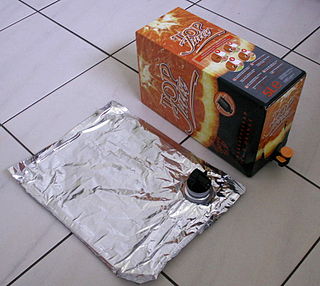

A bag-in-box or BiB is a container for the storage and transportation of liquids. It consists of a strong bladder, usually made of several layers of metallised film or other plastics, seated inside a corrugated fiberboard box.

A reamer is a type of rotary cutting tool used in metalworking. Precision reamers are designed to enlarge the size of a previously formed hole by a small amount but with a high degree of accuracy to leave smooth sides. There are also non-precision reamers which are used for more basic enlargement of holes or for removing burrs. The process of enlarging the hole is called reaming. There are many different types of reamer and they may be designed for use as a hand tool or in a machine tool, such as a milling machine or drill press.

Knurling is a manufacturing process, typically conducted on a lathe, whereby a pattern of straight, angled or crossed lines is rolled into the material. Knurling can also refer to material that has a knurled pattern.

Swaging is a forging process in which the dimensions of an item are altered using dies into which the item is forced. Swaging is usually a cold working process, but also may be hot worked.

Sheet metal is metal formed into thin, flat pieces, usually by an industrial process.

Punching is a forming process that uses a punch press to force a tool, called a punch, through the workpiece to create a hole via shearing. Punching is applicable to a wide variety of materials that come in sheet form, including sheet metal, paper, vulcanized fibre and some forms of plastic sheet. The punch often passes through the work into a die. A scrap slug from the hole is deposited into the die in the process. Depending on the material being punched this slug may be recycled and reused or discarded.

Leather crafting or simply leathercraft is the practice of making leather into craft objects or works of art, using shaping techniques, coloring techniques or both.

A punch is a tool used to indent or create a hole through a hard surface. They usually consist of a hard metal rod with a narrow tip at one end and a broad flat "butt" at the other. When used, the narrower end is pointed against a target surface and the broad end is then struck with a hammer or mallet, causing the blunt force of the blow to be transmitted down the rod body and focused more sharply onto a small area. Typically, woodworkers use a ball-peen hammer to strike a punch.

Continuous stationery (UK) or continuous form paper (US) is paper which is designed for use with dot-matrix and line printers with appropriate paper-feed mechanisms. Other names include fan-fold paper, sprocket-feed paper, burst paper, lineflow, tractor-feed paper, and pin-feed paper. It can be single-ply or multi-ply, often described as multipart stationery or forms. Continuous stationery is often used when the final print medium is less critical in terms of the appearance at the edges, and when continuously connected individual sheets are not inconvenient for the application. Individual sheets can be separated at the perforation, and sheets also have edges with punched holes, which also can be removed at the perforation.

In metallurgy, cold forming or cold working is any metalworking process in which metal is shaped below its recrystallization temperature, usually at the ambient temperature. Such processes are contrasted with hot working techniques like hot rolling, forging, welding, etc. The same or similar terms are used in glassmaking for the equivalents; for example cut glass is made by "cold work", cutting or grinding a formed object.

Perforated metal, also known as perforated sheet, perforated plate, or perforated screen, is sheet metal that has been manually or mechanically stamped or punched using CNC technology or in some cases laser cutting to create different holes sizes, shapes and patterns. Materials used to manufacture perforated metal sheets include stainless steel, cold rolled steel, galvanized steel, brass, aluminum, tinplate, copper, Monel, Inconel, titanium, plastic, and more.

Roll slitting is a shearing operation that cuts a large roll of material into narrower rolls. There are two types of slitting: log slitting and rewind slitting. In log slitting the roll of material is treated as a whole and one or more slices are taken from it without an unrolling/re-reeling process. In rewind slitting the web is unwound and run through the machine, passing through knives or lasers, before being rewound on one or more shafts to form narrower rolls. The multiple narrower strips of material may be known as mults or pancakes if their diameter is much more than their width. For rewind slitting the machine used is called a slitter rewinder, a slitter or a slitting machine – these names are used interchangeably for the same machines. For particularly narrow and thin products, the pancakes become unstable, and then the rewind may be onto a bobbin-wound reel: the rewind bobbins are much wider than the slit width and the web oscillates across the reel as it is rewound. Apart from the stability benefit it is also then possible to put very long lengths,, onto one bobbin.

Blanking and piercing are shearing processes in which a punch and die are used to produce parts from coil or sheet stock. Blanking produces the outside features of the component, while piercing produces internal holes or shapes. The web is created after multiple components have been produced and is considered scrap material. The "slugs" produced by piercing internal features are also considered scrap. The terms "piercing" and "punching" can be used interchangeably.

Staking is the process of connecting two components by creating an interference fit between the two pieces. One workpiece has a hole in it while the other has a boss that fits within the hole. The boss is very slightly undersized so that it forms a slip fit. A staking punch is then used to expand the boss radially and to compress the boss axially so as to form an interference fit between the workpieces. This forms a permanent joint.

Pollination bags, sometimes called crossing bags, isolation bags or exclusion bags, are containers made of various different materials for the purpose of controlling pollination for plants.

Friction stir spot welding is a pressure welding process that operates below the melting point of the workpieces. It is a variant of friction stir welding.