Related Research Articles

Maple syrup is a syrup made from the sap of maple trees. In cold climates, these trees store starch in their trunks and roots before winter; the starch is then converted to sugar that rises in the sap in late winter and early spring. Maple trees are tapped by drilling holes into their trunks and collecting the sap, which is processed by heating to evaporate much of the water, leaving the concentrated syrup.

A quality management system (QMS) is a collection of business processes focused on consistently meeting customer requirements and enhancing their satisfaction. It is aligned with an organization's purpose and strategic direction. It is expressed as the organizational goals and aspirations, policies, processes, documented information, and resources needed to implement and maintain it. Early quality management systems emphasized predictable outcomes of an industrial product production line, using simple statistics and random sampling. By the 20th century, labor inputs were typically the most costly inputs in most industrialized societies, so focus shifted to team cooperation and dynamics, especially the early signaling of problems via a continual improvement cycle. In the 21st century, QMS has tended to converge with sustainability and transparency initiatives, as both investor and customer satisfaction and perceived quality are increasingly tied to these factors. Of QMS regimes, the ISO 9000 family of standards is probably the most widely implemented worldwide – the ISO 19011 audit regime applies to both and deals with quality and sustainability and their integration.

In recipes, quantities of ingredients may be specified by mass, by volume, or by count.

The chemical industry comprises the companies and other organizations that develop and produce industrial, specialty and other chemicals. Central to the modern world economy, it converts raw materials into commodity chemicals for industrial and consumer products. It includes industries for petrochemicals such as polymers for plastics and synthetic fibers; inorganic chemicals such as acids and alkalis; agricultural chemicals such as fertilizers, pesticides and herbicides; and other categories such as industrial gases, speciality chemicals and pharmaceuticals.

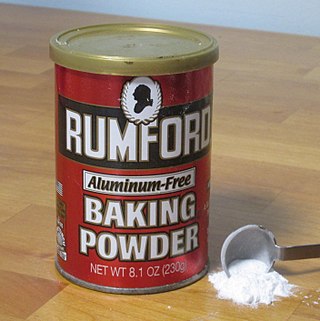

Baking powder is a dry chemical leavening agent, a mixture of a carbonate or bicarbonate and a weak acid. The base and acid are prevented from reacting prematurely by the inclusion of a buffer such as cornstarch. Baking powder is used to increase the volume and lighten the texture of baked goods. It works by releasing carbon dioxide gas into a batter or dough through an acid–base reaction, causing bubbles in the wet mixture to expand and thus leavening the mixture. The first single-acting baking powder was developed by food manufacturer Alfred Bird in England in 1843. The first double-acting baking powder, which releases some carbon dioxide when dampened and later releases more of the gas when heated by baking, was developed by Eben Norton Horsford in the U.S. in the 1860s.

Hazard analysis and critical control points, or HACCP, is a systematic preventive approach to food safety from biological, chemical, and physical hazards in production processes that can cause the finished product to be unsafe and designs measures to reduce these risks to a safe level. In this manner, HACCP attempts to avoid hazards rather than attempting to inspect finished products for the effects of those hazards. The HACCP system can be used at all stages of a food chain, from food production and preparation processes including packaging, distribution, etc. The Food and Drug Administration (FDA) and the United States Department of Agriculture (USDA) require mandatory HACCP programs for juice and meat as an effective approach to food safety and protecting public health. Meat HACCP systems are regulated by the USDA, while seafood and juice are regulated by the FDA. All other food companies in the United States that are required to register with the FDA under the Public Health Security and Bioterrorism Preparedness and Response Act of 2002, as well as firms outside the US that export food to the US, are transitioning to mandatory hazard analysis and risk-based preventive controls (HARPC) plans.

Jute is a long, rough, shiny bast fibre that can be spun into coarse, strong threads. It is produced from flowering plants in the genus Corchorus, of the mallow family Malvaceae. The primary source of the fiber is Corchorus olitorius, but such fiber is considered inferior to that derived from Corchorus capsularis.

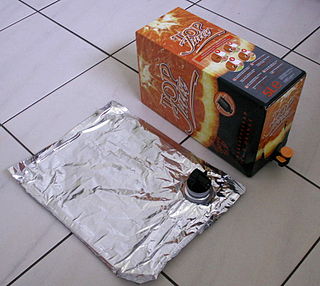

A bag-in-box or BiB is a container for the storage and transportation of liquids. It consists of a strong bladder, usually made of several layers of metallised film or other plastics, seated inside a corrugated fiberboard box.

A bill of materials or product structure is a list of the raw materials, sub-assemblies, intermediate assemblies, sub-components, parts, and the quantities of each needed to manufacture an end product. A BOM may be used for communication between manufacturing partners or confined to a single manufacturing plant. A bill of materials is often tied to a production order whose issuance may generate reservations for components in the bill of materials that are in stock and requisitions for components that are not in stock.

Enterprise software, also known as enterprise application software (EAS), is computer software used to satisfy the needs of an organization rather than its individual users. Enterprise software is an integral part of a computer-based information system, handling a number of business operations, for example to enhance business and management reporting tasks, or support production operations and back office functions. Enterprise systems must process information at a relatively high speed.

Intermediate bulk containers are industrial-grade containers engineered for the mass handling, transport, and storage of liquids, semi-solids, pastes, or solids. The two main categories of IBC tanks are flexible IBCs and rigid IBCs. Many IBCs are reused or repurposed.

A manufacturing bill of materials (MBOM), also referred to as the manufacturing BOM, contains all the parts and assemblies required to build a complete and shippable product.

Baker's percentage is a notation method indicating the proportion of an ingredient relative to the flour used in a recipe when making breads, cakes, muffins, and other baked goods. It is also referred to as baker's math, and may be indicated by a phrase such as based on flour weight. It is sometimes called formula percentage, a phrase that refers to the sum of a set of baker's percentages. Baker's percentage expresses a ratio in percentages of each ingredient's weight to the total flour weight:

Food safety is used as a scientific method/discipline describing handling, preparation, and storage of food in ways that prevent foodborne illness. The occurrence of two or more cases of a similar illness resulting from the ingestion of a common food is known as a food-borne disease outbreak. This includes a number of routines that should be followed to avoid potential health hazards. In this way, food safety often overlaps with food defense to prevent harm to consumers. The tracks within this line of thought are safety between industry and the market and then between the market and the consumer. In considering industry-to-market practices, food safety considerations include the origins of food including the practices relating to food labeling, food hygiene, food additives and pesticide residues, as well as policies on biotechnology and food and guidelines for the management of governmental import and export inspection and certification systems for foods. In considering market-to-consumer practices, the usual thought is that food ought to be safe in the market and the concern is safe delivery and preparation of the food for the consumer. Food safety, nutrition and food security are closely related. Unhealthy food creates a cycle of disease and malnutrition that affects infants and adults as well.

In business, engineering, and manufacturing, quality – or high quality – has a pragmatic interpretation as the non-inferiority or superiority of something ; it is also defined as being suitable for the intended purpose while satisfying customer expectations. Quality is a perceptual, conditional, and somewhat subjective attribute and may be understood differently by different people. Consumers may focus on the specification quality of a product/service, or how it compares to competitors in the marketplace. Producers might measure the conformance quality, or degree to which the product/service was produced correctly. Support personnel may measure quality in the degree that a product is reliable, maintainable, or sustainable. In such ways, the subjectivity of quality is rendered objective via operational definitions and measured with metrics such as proxy measures.

Aseptic processing is a processing technique wherein commercially thermally sterilized liquid products are packaged into previously sterilized containers under sterile conditions to produce shelf-stable products that do not need refrigeration. Aseptic processing has almost completely replaced in-container sterilization of liquid foods, including milk, fruit juices and concentrates, cream, yogurt, salad dressing, liquid egg, and ice cream mix. There has been an increasing popularity for foods that contain small discrete particles, such as cottage cheese, baby foods, tomato products, fruit and vegetables, soups, and rice desserts.

Manufacturing execution systems (MES) are computerized systems used in manufacturing to track and document the transformation of raw materials to finished goods. MES provides information that helps manufacturing decision-makers understand how current conditions on the plant floor can be optimized to improve production output. MES works as real-time monitoring system to enable the control of multiple elements of the production process.

Krones AG is a German packaging and bottling machine manufacturer. It produces lines for filling beverages in plastic and glass bottles or beverage cans. The company manufactures stretch blow-moulding machines for producing polyethylene terephthalate (PET) bottles, plus fillers, labellers, bottle washers, pasteurisers, inspectors, packers and palletisers. This product portfolio is complemented by material flow systems and process technology for producing beverages for breweries, dairies and soft-drink companies.

Plex Systems, Inc. is a software company based in Troy, Michigan. The company develops and markets the Plex Manufacturing Cloud, a software as a service (SaaS) or cloud computing ERP for manufacturing.

Cheese sauce is a sauce made with cheese or processed cheese as a primary ingredient. Sometimes dried cheese or cheese powder is used. Several varieties exist and it has many various culinary uses. Mass-produced commercial cheese sauces are also made by various companies, in both liquid and dry forms. These prepared sauces are used by consumers and restaurants, and commercial formulations are used in the production of various prepared foods, such as macaroni and cheese mixes and frozen meals.

References

- ↑ Difference Between Discrete and Process Manufacturing, BatchMaster Blog.

- ↑ "Process industry". collinsdictionary.com. Collins Dictionary.

- ↑ What is process manufacturing?, Process Manufacturing Definition, TechTarget.

- ↑ Litster, James; Bogle, David L. (December 2019). "Smart Process Manufacturing for Formulated Products" (PDF). Engineering. 5 (6): 1003–1009. doi: 10.1016/j.eng.2019.02.014 . S2CID 209781728.

- ↑ King, P.L.; Kroeger, D.R; Foster, J.B; Williams, N; Proctor, W (2008). "Making CEREAL not CARS" (PDF). Institute of Industrial and Systems Engineers. 40: 34-37.

- ↑ "Process Order Definition". help.sap.com. SAP.

- ↑ "Production Planning - Process Industries (PP-PI)". help.sap.com. SAP.

- ↑ Tosello, G (2014). "In-Process Inspection". CIRP Encyclopedia of Production Engineering. Berlin, Heidelberg: Springer. pp. 702–706. doi:10.1007/978-3-642-20617-7_6584. ISBN 978-3-642-20616-0.

- ↑ Wetherill, G.B; Brown, D.W (1992). Statistical Process Control for the Process Industries. Heidelberg: Physica. doi:10.1007/978-3-662-11789-7_17. ISBN 978-3-7908-0642-7.

- ↑ "Quality Management Principles". iso.org. ISO.

- ↑ "The Process Approach in ISO 9001:2015" (PDF). iso.org. ISO.

- ↑ "ISO 22000:2018 Food safety management systems — Requirements for any organization in the food chain". iso.org. ISO.