Project management is the process of leading the work of a team to achieve all project goals within the given constraints. This information is usually described in project documentation, created at the beginning of the development process. The primary constraints are scope, time, and budget. The secondary challenge is to optimize the allocation of necessary inputs and apply them to meet pre-defined objectives.

Operations research, often shortened to the initialism OR, is a discipline that deals with the development and application of analytical methods to improve decision-making. The term management science is occasionally used as a synonym.

Material requirements planning (MRP) is a production planning, scheduling, and inventory control system used to manage manufacturing processes. Most MRP systems are software-based, but it is possible to conduct MRP by hand as well.

Inventory or stock refers to the goods and materials that a business holds for the ultimate goal of resale, production or utilisation.

The theory of constraints (TOC) is a management paradigm that views any manageable system as being limited in achieving more of its goals by a very small number of constraints. There is always at least one constraint, and TOC uses a focusing process to identify the constraint and restructure the rest of the organization around it. TOC adopts the common idiom "a chain is no stronger than its weakest link". That means that organizations and processes are vulnerable because the weakest person or part can always damage or break them, or at least adversely affect the outcome.

Project management software (PMS) has the capacity to help plan, organize, and manage resource tools and develop resource estimates. Depending on the sophistication of the software, it can manage estimation and planning, scheduling, cost control and budget management, resource allocation, collaboration software, communication, decision-making, quality management, time management and documentation or administration systems. Numerous PC and browser-based project management software and contract management software products and services are available.

The program evaluation and review technique (PERT) is a statistical tool used in project management, which was designed to analyze and represent the tasks involved in completing a given project.

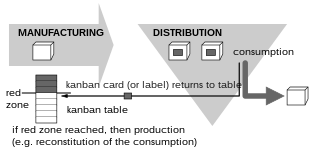

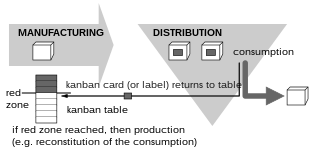

Kanban is a scheduling system for lean manufacturing. Taiichi Ohno, an industrial engineer at Toyota, developed kanban to improve manufacturing efficiency. The system takes its name from the cards that track production within a factory. Kanban is also known as the Toyota nameplate system in the automotive industry.

Operations management is an area of management concerned with designing and controlling the process of production and redesigning business operations in the production of goods or services. It involves the responsibility of ensuring that business operations are efficient in terms of using as few resources as needed and effective in meeting customer requirements.

Takt time, or simply takt, is a manufacturing term to describe the required product assembly duration that is needed to match the demand. Often confused with cycle time, takt time is a tool used to design work and it measures the average time interval between the start of production of one unit and the start of production of the next unit when items are produced sequentially. For calculations, it is the time to produce parts divided by the number of parts demanded in that time interval. The takt time is based on customer demand; if a process or a production line are unable to produce at takt time, either demand leveling, additional resources, or process re-engineering is needed to ensure on-time delivery.

Computational Engineering is an emerging discipline that deals with the development and application of computational models for engineering, known as Computational Engineering Models or CEM. At this time, various different approaches are summarized under the term Computational Engineering, including using computational geometry and virtual design for engineering tasks, often coupled with a simulation-driven approach In Computational Engineering, algorithms solve mathematical and logical models that describe engineering challenges, sometimes coupled with some aspect of AI, specifically Reinforcement Learning.

Factory Physics is a book written by Wallace Hopp and Mark Spearman, which introduces a science of operations for manufacturing management. According to the book's preface, Factory Physics is "a systematic description of the underlying behavior of manufacturing systems. Understanding it enables managers and engineers to work with the natural tendencies of manufacturing systems to:

A glossary of terms relating to project management and consulting.

Industrial engineering is an engineering profession that is concerned with the optimization of complex processes, systems, or organizations by developing, improving and implementing integrated systems of people, money, knowledge, information and equipment. Industrial engineering is central to manufacturing operations.

Applied engineering education is defined as a program that generally prepares individuals to apply mathematical and scientific principles inherent to engineering to the management and design of systems, execution of new product designs, improvement of manufacturing processes, and the management and direction of the physical or technical functions of an organization. Includes instruction in basic engineering principles, project management, industrial processes, production and operations management, systems integration and control, quality control, and statistics.14.0103 2020 CIP Code

The following outline is provided as an overview of and topical guide to production:

Industrial and production engineering (IPE) is an interdisciplinary engineering discipline that includes manufacturing technology, engineering sciences, management science, and optimization of complex processes, systems, or organizations. It is concerned with the understanding and application of engineering procedures in manufacturing processes and production methods. Industrial engineering dates back all the way to the industrial revolution, initiated in 1700s by Sir Adam Smith, Henry Ford, Eli Whitney, Frank Gilbreth and Lilian Gilbreth, Henry Gantt, F.W. Taylor, etc. After the 1970s, industrial and production engineering developed worldwide and started to widely use automation and robotics. Industrial and production engineering includes three areas: Mechanical engineering, industrial engineering, and management science.

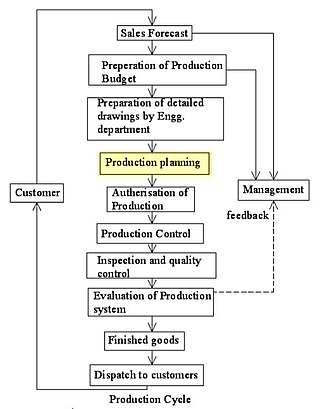

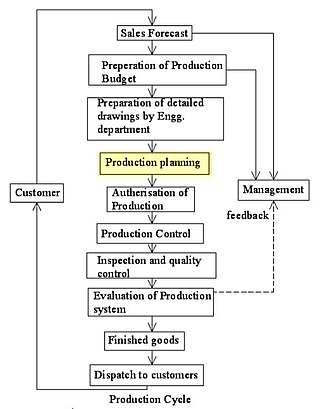

Production planning is the planning of production and manufacturing modules in a company or industry. It utilizes the resource allocation of activities of employees, materials and production capacity, in order to serve different customers.

Within supply chain management and manufacturing, production control is the activity of monitoring and controlling any particular production or operation. Production control is often run from a specific control room or operations room. With inventory control and quality control, production control is one of the key functions of operations management.

Donald G. Malcolm was an American organizational theorist, professor and dean at Cal State L.A.'s College of Business and Economics and management consultant, known as co-developer of the Performance, Evaluation, and Review Technique (PERT).