Recycling is the process of converting waste materials into new materials and objects. This concept often includes the recovery of energy from waste materials. The recyclability of a material depends on its ability to reacquire the properties it had in its original state. It is an alternative to "conventional" waste disposal that can save material and help lower greenhouse gas emissions. It can also prevent the waste of potentially useful materials and reduce the consumption of fresh raw materials, reducing energy use, air pollution and water pollution.

Asphalt concrete is a composite material commonly used to surface roads, parking lots, airports, and the core of embankment dams. Asphalt mixtures have been used in pavement construction since the beginning of the twentieth century. It consists of mineral aggregate bound together with bitumen, laid in layers, and compacted.

Polymer degradation is the reduction in the physical properties of a polymer, such as strength, caused by changes in its chemical composition. Polymers and particularly plastics are subject to degradation at all stages of their product life cycle, including during their initial processing, use, disposal into the environment and recycling. The rate of this degradation varies significantly; biodegradation can take decades, whereas some industrial processes can completely decompose a polymer in hours.

Scrap consists of recyclable materials, usually metals, left over from product manufacturing and consumption, such as parts of vehicles, building supplies, and surplus materials. Unlike waste, scrap has monetary value, especially recovered metals, and non-metallic materials are also recovered for recycling. Once collected, the materials are sorted into types — typically metal scrap will be crushed, shredded, and sorted using mechanical processes.

A materials recovery facility, materials reclamation facility, materials recycling facility or multi re-use facility is a specialized plant that receives, separates and prepares recyclable materials for marketing to end-user manufacturers. Generally, there are two different types: clean and dirty materials recovery facilities.

Plastic recycling is the processing of plastic waste into other products. Recycling can reduce dependence on landfill, conserve resources and protect the environment from plastic pollution and greenhouse gas emissions. Recycling rates lag those of other recoverable materials, such as aluminium, glass and paper. From the start of production through to 2015, the world produced some 6.3 billion tonnes of plastic waste, only 9% of which has been recycled, and only ~1% has been recycled more than once. Of the remaining waste, 12% was incinerated and 79% either sent to landfill or lost into the environment as pollution.

Municipal solid waste (MSW), commonly known as trash or garbage in the United States and rubbish in Britain, is a waste type consisting of everyday items that are discarded by the public. "Garbage" can also refer specifically to food waste, as in a garbage disposal; the two are sometimes collected separately. In the European Union, the semantic definition is 'mixed municipal waste,' given waste code 20 03 01 in the European Waste Catalog. Although the waste may originate from a number of sources that has nothing to do with a municipality, the traditional role of municipalities in collecting and managing these kinds of waste have produced the particular etymology 'municipal.'

Glass recycling is the processing of waste glass into usable products. Glass that is crushed or imploded and ready to be remelted is called cullet. There are two types of cullet: internal and external. Internal cullet is composed of defective products detected and rejected by a quality control process during the industrial process of glass manufacturing, transition phases of product changes and production offcuts. External cullet is waste glass that has been collected or reprocessed with the purpose of recycling. External cullet is classified as waste. The word "cullet", when used in the context of end-of-waste, will always refer to external cullet.

A mechanical biological treatment (MBT) system is a type of waste processing facility that combines a sorting facility with a form of biological treatment such as composting or anaerobic digestion. MBT plants are designed to process mixed household waste as well as commercial and industrial wastes.

Biodegradable plastics are plastics that can be decomposed by the action of living organisms, usually microbes, into water, carbon dioxide, and biomass. Biodegradable plastics are commonly produced with renewable raw materials, micro-organisms, petrochemicals, or combinations of all three.

The shredding of automobiles and major household appliances is a process where a hammermill acts as a giant tree chipper by grinding the materials fed into it to fist-size pieces. The shredding of automobiles results in a mixture of ferrous metal, non-ferrous metal and shredder waste, called automotive shredder residue or automobile shredder residue (ASR). ASR consists of glass, fiber, rubber, automobile liquids, plastics and dirt. ASR is sometimes differentiated into shredder light fraction and dust. Sometimes these residual materials are called "car-fluff".

Tire recycling, or rubber recycling, is the process of recycling waste tires that are no longer suitable for use on vehicles due to wear or irreparable damage. These tires are a challenging source of waste, due to the large volume produced, the durability of the tires, and the components in the tire that are ecologically problematic.

Upcycling, also known as creative reuse, is the process of transforming by-products, waste materials, useless, or unwanted products into new materials or products perceived to be of greater quality, such as artistic value or environmental value.

In 2015, 43.5% of the United Kingdom's municipal waste was recycled, composted or broken down by anaerobic digestion. The majority of recycling undertaken in the United Kingdom is done by statutory authorities, although commercial and industrial waste is chiefly processed by private companies. Local Authorities are responsible for the collection of municipal waste and operate contracts which are usually kerbside collection schemes. The Household Waste Recycling Act 2003 required local authorities in England to provide every household with a separate collection of at least two types of recyclable materials by 2010. Recycling policy is devolved to the administrations of Scotland, Northern Ireland and Wales who set their own targets, but all statistics are reported to Eurostat.

Demolition waste is waste debris from destruction of buildings, roads, bridges, or other structures. Debris varies in composition, but the major components, by weight, in the US include concrete, wood products, asphalt shingles, brick and clay tile, steel, and drywall. There is the potential to recycle many elements of demolition waste.

Plastics are a wide range of synthetic or semi-synthetic materials that use polymers as a main ingredient. Their plasticity makes it possible for plastics to be moulded, extruded or pressed into solid objects of various shapes. This adaptability, plus a wide range of other properties, such as being lightweight, durable, flexible, and inexpensive to produce, has led to its widespread use. Plastics typically are made through human industrial systems. Most modern plastics are derived from fossil fuel-based chemicals like natural gas or petroleum; however, recent industrial methods use variants made from renewable materials, such as corn or cotton derivatives.

Products made from a variety of materials can be recycled using a number of processes.

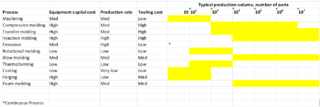

The economics of plastics processing is determined by the type of process. Plastics can be processed with the following methods: machining, compression molding, transfer molding, injection molding, extrusion, rotational molding, blow molding, thermoforming, casting, forging, and foam molding. Processing methods are selected based on equipment cost, production rate, tooling cost, and build volume. High equipment and tooling cost methods are typically used for large production volumes whereas low - medium equipment cost and tooling cost methods are used for low production volumes. Compression molding, transfer molding, injection molding, forging, and foam molding have high equipment and tooling cost. Lower cost processes are machining, extruding, rotational molding, blow molding, thermoforming, and casting. A summary of each process and its cost is displayed in figure 1.

Recycling in Australia is a widespread, and comprehensive part of waste management in Australia, with 60% of all waste collected being recycled. Recycling is collected from households, commercial businesses, industries and construction. Despite its prominence, household recycling makes up only a small part (13%) of Australia's total recycling. It generally occurs through kerbside recycling collections such as the commingled recycling bin and food/garden organics recycling bin, drop-off and take-back programs, and various other schemes. Collection and management of household recycling typically falls to local councils, with private contractors collecting commercial, industrial and construction recycling. In addition to local council regulations, legislation and overarching policies are implemented and managed by the state and federal governments.

China's waste import ban, instated at the end of 2017, prevented foreign inflows of waste products. Starting in early 2018, the government of China, under Operation National Sword, banned the import of several types of waste, including plastics with a contamination level of above 0.05 percent. The ban has greatly affected recycling industries worldwide, as China had been the world's largest importer of waste plastics and processed hard-to-recycle plastics for other countries, especially in the West.