Flour is a powder made by grinding raw grains, roots, beans, nuts, or seeds. Flours are used to make many different foods. Cereal flour, particularly wheat flour, is the main ingredient of bread, which is a staple food for many cultures. Corn flour has been important in Mesoamerican cuisine since ancient times and remains a staple in the Americas. Rye flour is a constituent of bread in both Central Europe and Northern Europe.

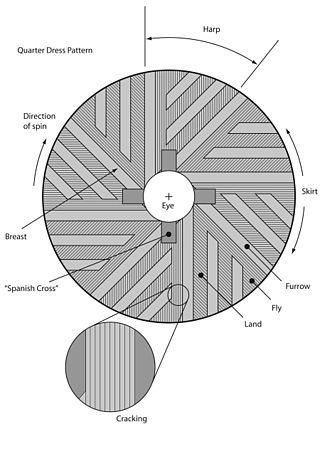

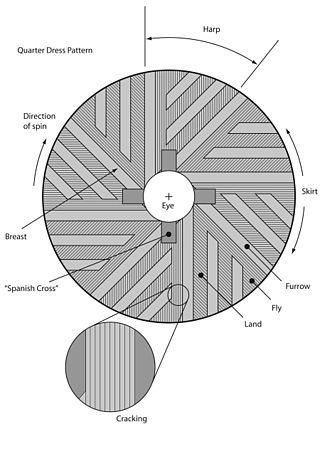

Millstones or mill stones are stones used in gristmills, used for triturating, crushing or, more specifically, grinding wheat or other grains. They are sometimes referred to as grindstones or grinding stones.

Wheat flour is a powder made from the grinding of wheat used for human consumption. Wheat varieties are called "soft" or "weak" if gluten content is low, and are called "hard" or "strong" if they have high gluten content. Hard flour, or bread flour, is high in gluten, with 12% to 14% gluten content, and its dough has elastic toughness that holds its shape well once baked. Soft flour is comparatively low in gluten and thus results in a loaf with a finer, crumbly texture. Soft flour is usually divided into cake flour, which is the lowest in gluten, and pastry flour, which has slightly more gluten than cake flour.

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell.

Quern-stones are stone tools for hand-grinding a wide variety of materials, especially for various types of grains. They are used in pairs. The lower stationary stone of early examples is called a saddle quern, while the upper mobile stone is called a muller, rubber, or handstone. The upper stone was moved in a back-and-forth motion across the saddle quern. Later querns are known as rotary querns. The central hole of a rotary quern is called the eye, and a dish in the upper surface is known as the hopper. A handle slot contained a handle which enabled the rotary quern to be rotated. They were first used in the Neolithic era to grind cereals into flour.

A mill is a device, often a structure, machine or home appliance, kitchen appliance, that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many processes. There are many different types of mills and many types of materials processed in them. Historically mills were powered by hand or by animals, working animal, wind (windmill) or water (watermill). In modern era, they are usually powered by electricity.

A stamp mill is a type of mill machine that crushes material by pounding rather than grinding, either for further processing or for extraction of metallic ores. Breaking material down is a type of unit operation.

A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. For example, a pulverizer mill is used to pulverize coal for combustion in the steam-generating furnaces of coal power plants.

Vienna bread is a type of bread that is produced from a process developed in Vienna, Austria, in the 19th century. The Vienna process used high milling of Hungarian grain, and cereal press-yeast for leavening.

A middlings purifier is a device used in the production of flour to remove the husks from the kernels of wheat. It was developed in Minnesota by Edmund LaCroix, a French inventor hired by Cadwallader C. Washburn and George Christian of the Washburn "A" Mill. It was developed to complement the emerging roller mill technique of the late 19th century, which used corrugated metal rollers instead of abrasive grindstones to grind wheat into flour. The middlings purifier was used to separate the bran from the usable part of the flour. The machine developed by LaCroix passed the partially ground middlings over a screen, and a stream of air blew away the particles of bran.

Vertical roller mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, cements and ceramics. It is an energy efficient alternative for a ball mill.

Maize miller is the processing of maize (corn) for safe and palatable consumption as food. Processing can be by machine-milling in either large- or small-scale mills, or by hand-milling in domestic or community settings.

A gristmill grinds cereal grain into flour and middlings. The term can refer to either the grinding mechanism or the building that holds it. Grist is grain that has been separated from its chaff in preparation for grinding.

A Unifine mill is a single one-pass impact milling system which produces ultrafine-milled whole-grain wheat flour that requires no grain pre-treatment and no screening of the flour. Like the grist or stone mills that had dominated the flour industry for centuries, the bran, germ, and endosperm elements of grain are processed into a nutritious whole wheat flour in one step. Consumers had accepted whole wheat products produced by grist or stone mills. The flour produced by these mills was quite coarse as they included the bran and the germ elements of the grain.

Annville Mill is thought to be one of the oldest continuously operating commercial flour mills in the United States, according to the local historical group, the Friends of Old Annville. A grist/flour mill has been standing since 1740 at this main street, now 545 W. Queen St, in Annville, Pennsylvania on the banks of Quittapahilla Creek, originally powered by water, but electrically powered since more than a century ago.

John Stevens was a miller and inventor who lived in Neenah, Wisconsin. His inventions in flour milling revolutionized the process, leading to large-scale shifts in wheat-growing regions, and to the predominance of particular milling companies and mill-equipment manufacturers. Today Patent flour is still referred to due to Stevens' patents.

Dry milling of grain is mainly utilized to manufacture feedstock into consumer and industrial based products. This process is widely associated with the development of new bio-based associated by-products. The milling process separates the grain into four distinct physical components: the germ, flour, fine grits, and coarse grits. The separated materials are then reduced into food products utilized for human and animal consumption.

The Roller Mill was created by Hungarian bakers in the late 1860s and its popularity spread worldwide throughout the 1900s. Roller mills now produce almost all non-whole grain flour. Enriched flour is flour that meets an FDA standard in the United States. Roller milled white enriched flour makes up over 90% of the flour that comes out of the United States.