A servo drive is an electronic amplifier used to power electric servomechanisms.

Contents

A servo drive monitors the feedback signal from the servomechanism and continually adjusts for deviation from expected behavior.

A servo drive is an electronic amplifier used to power electric servomechanisms.

A servo drive monitors the feedback signal from the servomechanism and continually adjusts for deviation from expected behavior.

A servo drive receives a command signal from a control system, amplifies the signal, and transmits electric current to a servo motor in order to produce motion proportional to the command signal. Typically, the command signal represents a desired velocity, but can also represent a desired torque or position. A sensor attached to the servo motor reports the motor's actual status back to the servo drive. The servo drive then compares the actual motor status with the commanded motor status. It then alters the voltage, frequency or pulse width to the motor so as to correct for any deviation from the commanded status. [1]

In a properly configured control system, the servo motor rotates at a velocity that very closely approximates the velocity signal being received by the servo drive from the control system. Several parameters, such as stiffness (also known as proportional gain), damping (also known as derivative gain), and feedback gain, can be adjusted to achieve this desired performance. The process of adjusting these parameters is called performance tuning.

Although many servo motors require a drive specific to that particular motor brand or model, many drives are now available that are compatible with a wide variety of motors..

All servo drives used in industry are digital, analog, or both. Digital drives differ from analog drives by having a microprocessor, or computer, which analyses incoming signals while controlling the mechanism. The microprocessor receives a pulse stream from an encoder which can determine parameters such as velocity. Varying the pulse, or blip, allows the mechanism to adjust speed essentially creating a speed controller effect. The repetitive tasks performed by a processor allows a digital drive to be quickly self-adjusting. In cases where mechanisms must adapt to many conditions, this can be convenient because a digital drive can adjust quickly with little effort. A drawback to digital drives is the large amount of energy that is consumed. However, many digital drives install capacity batteries to monitor battery life. The overall feedback system for a digital servo drive is like an analog, except that a microprocessor uses algorithms to predict system conditions.

Analog drives control velocity through various electrical inputs usually ±10 volts. Often adjusted with potentiometers, analog drives have plug in “personality cards” which are preadjusted to specific conditions. Most analog drives work by using a tach generator to measure incoming signals and produce a resulting torque demand. These torque demands request current in the mechanism depending on the feedback loop. This amplifier is referred as a four-quadrant drive because can accelerate, decelerate and brake in either rotating direction. Traditional analog drives consume less energy than digital drives and can offer very high performance in certain cases. When conditions are met, analog drives offer consistency with minimal “jitter” at standstills. Some analog servo drives do not need a torque amplifier and rely on velocity amplifiers for situation where speed is more important. [2] [3]

Servo systems can be used in CNC machining, factory automation, and robotics, among other uses. Their main advantage over traditional DC or AC motors is the addition of motor feedback. This feedback can be used to detect unwanted motion, or to ensure the accuracy of the commanded motion. The feedback is generally provided by an encoder of some sort. Servos, in constant speed changing use, have a better life cycle than typical AC wound motors. Servo motors can also act as a brake by shunting off generated electricity from the motor itself.

An analog computer or analogue computer is a type of computer that uses the continuous variation aspect of physical phenomena such as electrical, mechanical, or hydraulic quantities to model the problem being solved. In contrast, digital computers represent varying quantities symbolically and by discrete values of both time and amplitude.

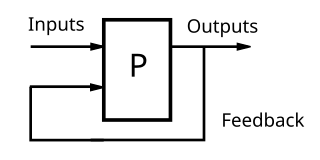

Feedback occurs when outputs of a system are routed back as inputs as part of a chain of cause-and-effect that forms a circuit or loop. The system can then be said to feed back into itself. The notion of cause-and-effect has to be handled carefully when applied to feedback systems:

Simple causal reasoning about a feedback system is difficult because the first system influences the second and second system influences the first, leading to a circular argument. This makes reasoning based upon cause and effect tricky, and it is necessary to analyze the system as a whole.

Pulse-width modulation (PWM), or pulse-duration modulation (PDM), is a method of reducing the average power delivered by an electrical signal, by effectively chopping it up into discrete parts. The average value of voltage fed to the load is controlled by turning the switch between supply and load on and off at a fast rate. The longer the switch is on compared to the off periods, the higher the total power supplied to the load. Along with maximum power point tracking (MPPT), it is one of the primary methods of reducing the output of solar panels to that which can be utilized by a battery. PWM is particularly suited for running inertial loads such as motors, which are not as easily affected by this discrete switching, because their inertia causes them to react slowly. The PWM switching frequency has to be high enough not to affect the load, which is to say that the resultant waveform perceived by the load must be as smooth as possible.

A radio-controlled model is a model that is steerable with the use of radio control. All types of model vehicles have had RC systems installed in them, including ground vehicles, boats, planes, helicopters and even submarines and scale railway locomotives.

A stepper motor, also known as step motor or stepping motor, is a brushless DC electric motor that divides a full rotation into a number of equal steps. The motor's position can be commanded to move and hold at one of these steps without any position sensor for feedback, as long as the motor is correctly sized to the application in respect to torque and speed.

In control engineering a servomechanism, usually shortened to servo, is an automatic device that uses error-sensing negative feedback to correct the action of a mechanism. On displacement-controlled applications, it usually includes a built-in encoder or other position feedback mechanism to ensure the output is achieving the desired effect.

In an open-loop controller, also called a non-feedback controller, the control action from the controller is independent of the "process output", which is the process variable that is being controlled. It does not use feedback to determine if its output has achieved the desired goal of the input command or process "set point".

Numerical control is the automated control of machining tools by means of a computer. A CNC machine processes a piece of material to meet specifications by following coded programmed instructions and without a manual operator directly controlling the machining operation.

A brushless DC electric motor, also known as an electronically commutated motor or synchronous DC motor, is a synchronous motor using a direct current (DC) electric power supply. It uses an electronic controller to switch DC currents to the motor windings producing magnetic fields which effectively rotate in space and which the permanent magnet rotor follows. The controller adjusts the phase and amplitude of the DC current pulses to control the speed and torque of the motor. This control system is an alternative to the mechanical commutator (brushes) used in many conventional electric motors.

A synchro is, in effect, a transformer whose primary-to-secondary coupling may be varied by physically changing the relative orientation of the two windings. Synchros are often used for measuring the angle of a rotating machine such as an antenna platform. In its general physical construction, it is much like an electric motor. The primary winding of the transformer, fixed to the rotor, is excited by an alternating current, which by electromagnetic induction, causes voltages to appear between the Y-connected secondary windings fixed at 120 degrees to each other on the stator. The voltages are measured and used to determine the angle of the rotor relative to the stator.

A chart recorder is an electromechanical device that records an electrical or mechanical input trend onto a piece of paper. Chart recorders may record several inputs using different color pens and may record onto strip charts or circular charts. Chart recorders may be entirely mechanical with clockwork mechanisms, electro-mechanical with an electrical clockwork mechanism for driving the chart, or entirely electronic with no mechanical components at all.

Motion control is a sub-field of automation, encompassing the systems or sub-systems involved in moving parts of machines in a controlled manner. Motion control systems are extensively used in a variety of fields for automation purposes, including precision engineering, micromanufacturing, biotechnology, and nanotechnology. The main components involved typically include a motion controller, an energy amplifier, and one or more prime movers or actuators. Motion control may be open loop or closed loop. In open loop systems, the controller sends a command through the amplifier to the prime mover or actuator, and does not know if the desired motion was actually achieved. Typical systems include stepper motor or fan control. For tighter control with more precision, a measuring device may be added to the system. When the measurement is converted to a signal that is sent back to the controller, and the controller compensates for any error, it becomes a Closed loop System.

A servomotor is a rotary actuator or linear actuator that allows for precise control of angular or linear position, velocity and acceleration. It consists of a suitable motor coupled to a sensor for position feedback. It also requires a relatively sophisticated controller, often a dedicated module designed specifically for use with servomotors.

A torque motor is a specialized form of DC electric motor which can operate indefinitely while stalled, without incurring damage. In this mode of operation, the motor will apply a steady torque to the load. A torque motor that cannot perform a complete rotation is known as a limited angle torque motor. Brushless torque motors are available; elimination of commutators and brushes allows higher speed operation.

Vector control, also called field-oriented control (FOC), is a variable-frequency drive (VFD) control method in which the stator currents of a three-phase AC or brushless DC electric motor are identified as two orthogonal components that can be visualized with a vector. One component defines the magnetic flux of the motor, the other the torque. The control system of the drive calculates the corresponding current component references from the flux and torque references given by the drive's speed control. Typically proportional-integral (PI) controllers are used to keep the measured current components at their reference values. The pulse-width modulation of the variable-frequency drive defines the transistor switching according to the stator voltage references that are the output of the PI current controllers.

An electrohydraulic servo valve (EHSV) is an electrically-operated valve that controls how hydraulic fluid is sent to an actuator. Servo valves are often used to control powerful hydraulic cylinders with a very small electrical signal. Servo valves can provide precise control of position, velocity, pressure, and force with good post-movement damping characteristics.

Minor loop feedback is a classical method used to design stable robust linear feedback control systems using feedback loops around sub-systems within the overall feedback loop. The method is sometimes called minor loop synthesis in college textbooks, some government documents.

Servos are small, cheap, mass-produced servomotors or other actuators used for radio control and small-scale robotics.

A torque amplifier is a mechanical device that amplifies the torque of a rotating shaft without affecting its rotational speed. It is mechanically related to the capstan seen on ships. Its most widely known use is in power steering on automobiles. Another use is on the differential analyzer, where it was used to increase the output torque of the otherwise limited ball-and-disk integrator. The term is also applied to some gearboxes used on tractors, although this is unrelated. It differs from a torque converter, in which the rotational speed of the output shaft decreases as the torque increases.

Direct-drive sim racing wheel systems are a method of control for use in racing video games, racing simulators, and driving simulators, that produce force feedback using a direct-drive servo motor that directly transmits forces to the shaft and wheel rim, without any reduction gears or belts. They have been introduced in 2013, as a more high-end alternative to gear- and belt-driven mass market consumer racing wheels. The first commercially broadly available direct-drive sim racing wheel base has been released in 2013 by the UK-based Leo Bodnar Electronics, after having been retailing to racing teams and professional centers since 2008. It was followed in 2015 by the US-based SimXperience AccuForce V1, and by the first DIY open-source hardware "OSW" kits.