Recycling is the process of converting waste materials into new materials and objects. This concept often includes the recovery of energy from waste materials. The recyclability of a material depends on its ability to reacquire the properties it had in its original state. It is an alternative to "conventional" waste disposal that can save material and help lower greenhouse gas emissions. It can also prevent the waste of potentially useful materials and reduce the consumption of fresh raw materials, reducing energy use, air pollution and water pollution.

Waste management or waste disposal includes the processes and actions required to manage waste from its inception to its final disposal. This includes the collection, transport, treatment, and disposal of waste, together with monitoring and regulation of the waste management process and waste-related laws, technologies, and economic mechanisms.

Post-consumer waste is a waste type produced by the end consumer of a material stream; that is, where the waste-producing use did not involve the production of another product.

Extended producer responsibility (EPR) is a strategy to add all of the estimated environmental costs associated with a product throughout the product life cycle to the market price of that product, contemporarily mainly applied in the field of waste management. Such societal costs are typically externalities to market mechanisms, with a common example being the impact of cars.

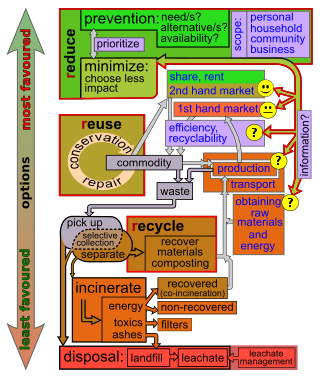

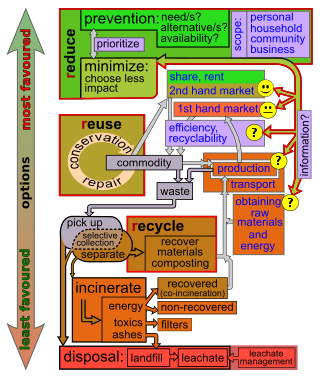

Zero waste, or waste minimization, is a set of principles focused on waste prevention that encourages redesigning resource life cycles so that all products are repurposed and/or reused. The goal of the movement is to avoid sending trash to landfills, incinerators, oceans, or any other part of the environment. Currently 9% of global plastic is recycled. In a zero waste system, all materials are reused until the optimum level of consumption is reached.

Electronic waste recycling, electronics recycling, or e-waste recycling is the disassembly and separation of components and raw materials of waste electronics; when referring to specific types of e-waste, the terms like computer recycling or mobile phone recycling may be used. Like other waste streams, reuse, donation, and repair are common sustainable ways to dispose of IT waste.

Reuse is the action or practice of using an item, whether for its original purpose or to fulfill a different function. It should be distinguished from recycling, which is the breaking down of used items to make raw materials for the manufacture of new products. Reuse—by taking, but not reprocessing, previously used items—helps save time, money, energy and resources. In broader economic terms, it can make quality products available to people and organizations with limited means, while generating jobs and business activity that contribute to the economy.

Waste minimisation is a set of processes and practices intended to reduce the amount of waste produced. By reducing or eliminating the generation of harmful and persistent wastes, waste minimisation supports efforts to promote a more sustainable society. Waste minimisation involves redesigning products and processes and/or changing societal patterns of consumption and production.

Precycling is the practice of reducing waste by attempting to avoid buying items which will generate waste into home or business. The U.S. Environmental Protection Agency (EPA) also cites that precycling is the preferred method of integrated solid waste management because it cuts waste at its source and therefore trash is eliminated before it is created. According to the EPA, precycling is also characterized as a decision-making process on the behalf of the consumer because it involves making informed judgments regarding a product's waste implications. The implications that are taken into consideration by the consumer include: whether a product is reusable, durable, or repairable; made from renewable or non-renewable resources; over-packaged; and whether or not the container is reusable.

Recycling in Japan, an aspect of waste management in Japan, is based on the Japanese Container and Packaging Recycling Law. Plastic, paper, PET bottles, aluminium and glass are collected and recycled. Japan's country profile in Waste Atlas shows that in 2012 Recycling Rate was 20.8%.

Waste management in Japan today emphasizes not just the efficient and sanitary collection of waste, but also reduction in waste produced and recycling of waste when possible. This has been influenced by its history, particularly periods of significant economic expansion, as well as its geography as a mountainous country with limited space for landfills. Important forms of waste disposal include incineration, recycling and, to a smaller extent, landfills and land reclamation. Although Japan has made progress since the 1990s in reducing waste produced and encouraging recycling, there is still further progress to be made in reducing reliance on incinerators and the garbage sent to landfills. Challenges also exist in the processing of electronic waste and debris left after natural disasters.

Mobile phone recycling describes the waste management of mobile phones, to retrieve materials used in their manufacture. Rapid technology change, low initial cost, and planned obsolescence have resulted in a fast-growing surplus, which contributes to the increasing amount of electronic waste around the globe.

The City of Oakland, California, adopted a Zero Waste Strategic Plan in 2006, detailing a road map for the city to follow toward the implementation of a Zero Waste System by 2020. As stated in a City Resolution, introduced by then Mayor Jerry Brown, Zero Waste principles:

A circular economy is a model of resource production and consumption in any economy that involves sharing, leasing, reusing, repairing, refurbishing, and recycling existing materials and products for as long as possible. The concept aims to tackle global challenges such as climate change, biodiversity loss, waste, and pollution by emphasizing the design-based implementation of the three base principles of the model. The three principles required for the transformation to a circular economy are: designing out waste and pollution; keeping products and materials in use, and regenerating natural systems. CE is defined in contradistinction to the traditional linear economy. The idea and concepts of a circular economy have been studied extensively in academia, business, and government over the past ten years. It has been gaining popularity because it can help to minimize carbon emissions and the consumption of raw materials, open up new market prospects, and, principally, increase the sustainability of consumption.

Sustainable distribution refers to any means of transportation / hauling of goods between vendor and purchaser with lowest possible impact on the ecological and social environment, and includes the whole distribution process from storage, order processing and picking, packaging, improved vehicle loadings, delivery to the customer or purchaser and taking back packaging.

Resource recovery is using wastes as an input material to create valuable products as new outputs. The aim is to reduce the amount of waste generated, thereby reducing the need for landfill space, and optimising the values created from waste. Resource recovery delays the need to use raw materials in the manufacturing process. Materials found in municipal solid waste, construction and demolition waste, commercial waste and industrial wastes can be used to recover resources for the manufacturing of new materials and products. Plastic, paper, aluminium, glass and metal are examples of where value can be found in waste.

Sustainable Materials Management is a systemic approach to using and reusing materials more productively over their entire lifecycles. It represents a change in how a society thinks about the use of natural resources and environmental protection. By looking at a product's entire lifecycle new opportunities can be found to reduce environmental impacts, conserve resources, and reduce costs.

A circular economy is an alternative way countries manage their resources, where instead of using products in the traditional linear make, use, dispose method, resources are used for their maximum utility throughout their life cycle and regenerated in a cyclical pattern minimizing waste. They strive to create economic development through environmental and resource protection. The ideas of a circular economy were officially adopted by China in 2002, when the 16th National Congress of the Chinese Communist Party legislated it as a national endeavour, though various sustainability initiatives were implemented in the previous decades starting in 1973. China adopted the circular economy due to the environmental damage and resource depletion that was occurring from going through its industrialization process. China is currently a world leader in the production of resources, where it produces 46% of the world's aluminum, 50% of steel and 60% of cement, while it has consumed more raw materials than all the countries a part of the Organisation for Economic Co-operation and Development (OECD) combined. In 2014, China created 3.2 billion tonnes of industrial solid waste, where 2 billion tonnes were recovered using recycling, incineration, reusing and composting. By 2025, China is anticipated to produce up to one quarter of the world's municipal solid waste.

Closed-loop recycling is the process by which a product or material can be used and then turned into a new product indefinitely without losing its properties during the recycling process.

Closed Loop Box Reuse, is the process by which boxes or other containers are reused many times. It is a form of reusable packaging.