A shovel is a tool used for digging, lifting, and moving bulk materials, such as soil, coal, gravel, snow, sand, or ore. Most shovels are hand tools consisting of a broad blade fixed to a medium-length handle. Shovel blades are usually made of sheet steel or hard plastics and are very strong. Shovel handles are usually made of wood or glass-reinforced plastic (fiberglass).

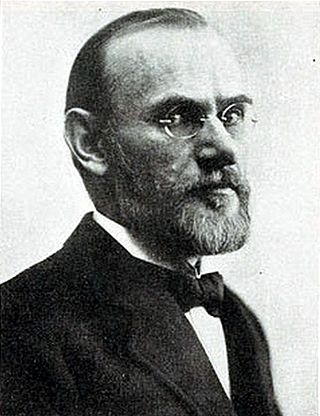

Frederick Winslow Taylor was an American mechanical engineer. He was widely known for his methods to improve industrial efficiency. He was one of the first management consultants. In 1909, Taylor summed up his efficiency techniques in his book The Principles of Scientific Management which, in 2001, Fellows of the Academy of Management voted the most influential management book of the twentieth century. His pioneering work in applying engineering principles to the work done on the factory floor was instrumental in the creation and development of the branch of engineering that is now known as industrial engineering. Taylor made his name, and was most proud of his work, in scientific management; however, he made his fortune patenting steel-process improvements. As a result, scientific management is sometimes referred to as Taylorism.

Scientific management is a theory of management that analyzes and synthesizes workflows. Its main objective is improving economic efficiency, especially labor productivity. It was one of the earliest attempts to apply science to the engineering of processes to management. Scientific management is sometimes known as Taylorism after its pioneer, Frederick Winslow Taylor.

Henry Laurence Gantt was an American mechanical engineer and management consultant who is best known for his work in the development of scientific management. He created the Gantt chart in the 1910s.

Organizational theory refers to a series of interrelated concepts that involve the sociological study of the structures and operations of formal social organizations. Organizational theory also seeks to explain how interrelated units of organization either connect or do not connect with each other. Organizational theory also concerns understanding how groups of individuals behave, which may differ from the behavior of an individual. The behavior organizational theory often focuses on is goal-directed. Organizational theory covers both intra-organizational and inter-organizational fields of study.

A time and motion study is a business efficiency technique combining the Time Study work of Frederick Winslow Taylor with the Motion Study work of Frank and Lillian Gilbreth. It is a major part of scientific management (Taylorism). After its first introduction, time study developed in the direction of establishing standard times, while motion study evolved into a technique for improving work methods. The two techniques became integrated and refined into a widely accepted method applicable to the improvement and upgrading of work systems. This integrated approach to work system improvement is known as methods engineering and it is applied today to industrial as well as service organizations, including banks, schools and hospitals.

A man-hour or human-hour is the amount of work performed by the average worker in one hour. It is used for estimation of the total amount of uninterrupted labor required to perform a task. For example, researching and writing a college paper might require eighty man-hours, while preparing a family banquet from scratch might require ten man-hours.

Operations management is concerned with designing and controlling the production of goods and services, ensuring that businesses are efficient in using resources to meet customer requirements.

Leon Pratt Alford was an American mechanical engineer, organizational theorist, and administrator for the American Society of Mechanical Engineers. known for his seminal work in the field of industrial management.

The efficiency movement was a major movement in the United States, Britain and other industrial nations in the early 20th century that sought to identify and eliminate waste in all areas of the economy and society, and to develop and implement best practices. The concept covered mechanical, economic, social, and personal improvement. The quest for efficiency promised effective, dynamic management rewarded by growth.

Henry Robinson Towne was an American mechanical engineer and businessman, known as an early systematizer of management. He donated several millions to philanthropy at his death, in 1924.

Carl Georg Lange Barth was a Norwegian-American mathematician, mechanical and consulting engineer, and lecturer at Harvard University. Barth is known as one of the foreman of scientific management, who improved and popularized the industrial use of compound slide rules.

Manual labour or manual work is physical work done by humans, in contrast to labour by machines and working animals. It is most literally work done with the hands and, by figurative extension, it is work done with any of the muscles and bones of the human body. For most of human prehistory and history, manual labour and its close cousin, animal labour, have been the primary ways that physical work has been accomplished. Mechanisation and automation, which reduce the need for human and animal labour in production, have existed for centuries, but it was only starting in the 18th and 19th centuries that they began to significantly expand and to change human culture. To be implemented, they require that sufficient technology exist and that its capital costs be justified by the amount of future wages that they will obviate. Semi-automation is an alternative to worker displacement that combines human labour, automation, and computerisation to leverage the advantages of both man and machine.

Henry Noll (1871–1925) was a resident of Bethlehem, Pennsylvania, made famous in a anecdote used by Frederick Winslow Taylor to illustrate his theories of scientific management.

Morris Llewellyn Cooke was an American engineer, best known for his work on Scientific Management and Rural Electrification.

Harrington Emerson was an American efficiency engineer and business theorist, who founded the management consultancy firm Emerson Institute in New York City in 1900. Known for his pioneering contributions to scientific management, Emerson may have done more than anyone else to popularize the topic: His public testimony in 1910 to the Interstate Commerce Commission that the railroads could save $1,000,000 a day started a nationwide interest in the subject of "efficiency".

Frederick Arthur Halsey was an American mechanical engineer and economist, who was long-time editor of the American Machinist magazine, and particularly known for his 1891 article, entitled "The premium plan of paying for labor."

The Taylor Society was an American society for the discussion and promotion of scientific management, named after Frederick Winslow Taylor.

Schmidt is a character in Principles of Scientific Management by Frederick Winslow Taylor. His true identity was Henry Noll.

Horace Bookwalter Drury was an American economist, lecturer at Ohio State University, and management author, particularly known for his early work on scientific management.