Metalworking is the process of shaping and reshaping metals to create useful objects, parts, assemblies, and large scale structures. As a term it covers a wide and diverse range of processes, skills, and tools for producing objects on every scale: from huge ships, buildings, and bridges down to precise engine parts and delicate jewelry.

Machining is a manufacturing process whereby a desired shape or part is achieved by the controlled removal of material from a larger piece of raw material by cutting; it is most often performed with metal material. These processes are collectively called subtractive manufacturing, which utilizes machine tools, in contrast to additive manufacturing, which uses controlled addition of material.

Induction heating is the process of heating electrically conductive materials, namely metals or semi-conductors, by electromagnetic induction, through heat transfer passing through an inductor that creates an electromagnetic field within the coil to heat up and possibly melt steel, copper, brass, graphite, gold, silver, aluminum, or carbide.

In machining, numerical control, also called computer numerical control (CNC), is the automated control of tools by means of a computer. It is used to operate tools such as drills, lathes, mills, grinders, routers and 3D printers. CNC transforms a piece of material into a specified shape by following coded programmed instructions and without a manual operator directly controlling the machining operation.

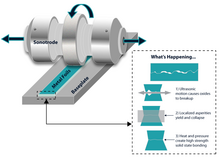

Ultrasonic welding is an industrial process whereby high-frequency ultrasonic acoustic vibrations are locally applied to work pieces being held together under pressure to create a solid-state weld. It is commonly used for plastics and metals, and especially for joining dissimilar materials. In ultrasonic welding, there are no connective bolts, nails, soldering materials, or adhesives necessary to bind the materials together. When used to join metals, the temperature stays well below the melting point of the involved materials, preventing any unwanted properties which may arise from high temperature exposure of the metal.

Plastic welding is welding for semi-finished plastic materials, and is described in ISO 472 as a process of uniting softened surfaces of materials, generally with the aid of heat. Welding of thermoplastics is accomplished in three sequential stages, namely surface preparation, application of heat and pressure, and cooling. Numerous welding methods have been developed for the joining of semi-finished plastic materials. Based on the mechanism of heat generation at the welding interface, welding methods for thermoplastics can be classified as external and internal heating methods, as shown in Fig 1.

3D printing or additive manufacturing is the construction of a three-dimensional object from a CAD model or a digital 3D model. It can be done in a variety of processes in which material is deposited, joined or solidified under computer control, with the material being added together, typically layer by layer.

Galling is a form of wear caused by adhesion between sliding surfaces. When a material galls, some of it is pulled with the contacting surface, especially if there is a large amount of force compressing the surfaces together. Galling is caused by a combination of friction and adhesion between the surfaces, followed by slipping and tearing of crystal structure beneath the surface. This will generally leave some material stuck or even friction welded to the adjacent surface, whereas the galled material may appear gouged with balled-up or torn lumps of material stuck to its surface.

A burr is a raised edge or small piece of material that remains attached to a workpiece after a modification process. It is usually an unwanted piece of material and is removed with a deburring tool in a process called deburring. Burrs are most commonly created by machining operations, such as grinding, drilling, milling, engraving or turning. It may be present in the form of a fine wire on the edge of a freshly sharpened tool or as a raised portion of a surface; this type of burr is commonly formed when a hammer strikes a surface. Deburring accounts for a significant portion of manufacturing costs.

Electron-beam additive manufacturing, or electron-beam melting (EBM) is a type of additive manufacturing, or 3D printing, for metal parts. The raw material is placed under a vacuum and fused together from heating by an electron beam. This technique is distinct from selective laser sintering as the raw material fuses having completely melted.

Digital modeling and fabrication is a design and production process that combines 3D modeling or computing-aided design (CAD) with additive and subtractive manufacturing. Additive manufacturing is also known as 3D printing, while subtractive manufacturing may also be referred to as machining, and many other technologies can be exploited to physically produce the designed objects.

Low plasticity burnishing (LPB) is a method of metal improvement that provides deep, stable surface compressive residual stresses with little cold work for improved damage tolerance and metal fatigue life extension. Improved fretting fatigue and stress corrosion performance has been documented, even at elevated temperatures where the compression from other metal improvement processes relax. The resulting deep layer of compressive residual stress has also been shown to improve high cycle fatigue (HCF) and low cycle fatigue (LCF) performance.

Cladding is the bonding together of dissimilar metals. It is different from fusion welding or gluing as a method to fasten the metals together. Cladding is often achieved by extruding two metals through a die as well as pressing or rolling sheets together under high pressure.

Binder jet 3D printing, known variously as "Powder bed and inkjet" and "drop-on-powder" printing, is a rapid prototyping and additive manufacturing technology for making objects described by digital data such as a CAD file. Binder jetting is one of the seven categories of additive manufacturing processes according to ASTM and ISO.

Diffusion bonding or diffusion welding is a solid-state welding technique used in metalworking, capable of joining similar and dissimilar metals. It operates on the principle of solid-state diffusion, wherein the atoms of two solid, metallic surfaces intersperse themselves over time. This is typically accomplished at an elevated temperature, approximately 50-75% of the absolute melting temperature of the materials. A weak bond can also be achieved at room temperature. Diffusion bonding is usually implemented by applying high pressure, in conjunction with necessarily high temperature, to the materials to be welded; the technique is most commonly used to weld "sandwiches" of alternating layers of thin metal foil, and metal wires or filaments. Currently, the diffusion bonding method is widely used in the joining of high-strength and refractory metals within the aerospace and nuclear industries.

A variety of processes, equipment, and materials are used in the production of a three-dimensional object via additive manufacturing. 3D printing is also known as additive manufacturing, because the numerous available 3D printing process tend to be additive in nature, with a few key differences in the technologies and the materials used in this process.

Aluminium alloys are often used due to their high strength-to-weight ratio, corrosion resistance, low cost, high thermal and electrical conductivity. There are a variety of techniques to join aluminium including mechanical fasteners, welding, adhesive bonding, brazing, soldering and friction stir welding (FSW), etc. Various techniques are used based on the cost and strength required for the joint. In addition, process combinations can be performed to provide means for difficult-to-join assemblies and to reduce certain process limitations.

Ultrasonic welding is a method of joining thermoplastic components by heating and subsequent melting of surfaces in contact. Mechanical vibration with frequency between 10 and 70 kHz and amplitude of 10 to 250 μm is applied to joining parts. After ultrasonic energy is turned off, the parts remain in contact under pressure for some time while the melt layer cools down creating a weld.

Advanced thermoplastic composites (ACM) have a high strength fibres held together by a thermoplastic matrix. Advanced thermoplastic composites are becoming more widely used in the aerospace, marine, automotive and energy industry. This is due to the decreasing cost and superior strength to weight ratios, over metallic parts. Advance thermoplastic composite have excellent damage tolerance, corrosion resistant, high fracture toughness, high impact resistance, good fatigue resistance, low storage cost, and infinite shelf life. Thermoplastic composites also have the ability to be formed and reformed, repaired and fusion welded.

Laser polishing, also referred to as laser re-melting, is a type of micro-melting process employed for improving surface quality of materials. As opposed to other conventional polishing processes, this process does not involve removal of materials from the workpiece surface. In this process, the laser is made incident on the workpiece to melt the surface down to a certain depth, thus enabling subsequent betterment of surface parameters due to re-solidification of the melted material.