Heating, ventilation, and air conditioning (HVAC) is the use of various technologies to control the temperature, humidity, and purity of the air in an enclosed space. Its goal is to provide thermal comfort and acceptable indoor air quality. HVAC system design is a subdiscipline of mechanical engineering, based on the principles of thermodynamics, fluid mechanics, and heat transfer. "Refrigeration" is sometimes added to the field's abbreviation as HVAC&R or HVACR, or "ventilation" is dropped, as in HACR.

A furnace, referred to as a heater or boiler in British English, is an appliance used to generate heat for all or part of a building. Furnaces are mostly used as a major component of a central heating system. Furnaces are permanently installed to provide heat to an interior space through intermediary fluid movement, which may be air, steam, or hot water. Heating appliances that use steam or hot water as the fluid are normally referred to as a residential steam boilers or residential hot water boilers. The most common fuel source for modern furnaces in North America and much of Europe is natural gas; other common fuel sources include LPG, fuel oil, wood and in rare cases coal. In some areas electrical resistance heating is used, especially where the cost of electricity is low or the primary purpose is for air conditioning. Modern high-efficiency furnaces can be up to 98% efficient and operate without a chimney, with a typical gas furnace being about 80% efficient. Waste gas and heat are mechanically ventilated through either metal flue pipes or polyvinyl chloride (PVC) pipes that can be vented through the side or roof of the structure. Fuel efficiency in a gas furnace is measured in AFUE.

A central heating system provides warmth to a number of spaces within a building from one main source of heat. It is a component of heating, ventilation, and air conditioning systems, which can both cool and warm interior spaces.

Hydronics is the use of liquid water or gaseous water (steam) or a water solution as heat-transfer medium in heating and cooling systems. The name differentiates such systems from oil and refrigerant systems.

Cross-linked polyethylene, commonly abbreviated PEX, XPE or XLPE, is a form of polyethylene with cross-links. It is used predominantly in building services pipework systems, hydronic radiant heating and cooling systems, domestic water piping, insulation for high tension electrical cables, and baby play mats. It is also used for natural gas and offshore oil applications, chemical transportation, and transportation of sewage and slurries. PEX is an alternative to polyvinyl chloride (PVC), chlorinated polyvinyl chloride (CPVC) or copper tubing for use as residential water pipes.

Designated as an American National Standard, the Uniform Plumbing Code (UPC) is a model code developed by the International Association of Plumbing and Mechanical Officials (IAPMO) to govern the installation and inspection of plumbing systems as a means of promoting the public's health, safety and welfare.

Underfloor heating and cooling is a form of central heating and cooling that achieves indoor climate control for thermal comfort using hydronic or electrical heating elements embedded in a floor. Heating is achieved by conduction, radiation and convection. Use of underfloor heating dates back to the Neoglacial and Neolithic periods.

Building officials of developed countries are generally the jurisdictional administrator of building and construction codes, engineering calculation supervision, permits, facilities management, and accepted construction procedures.

Building services engineering (BSE) is a professional engineering discipline that strives to achieve a safe and comfortable indoor environment whilst minimizing the environmental impact of a building.

Designated as an American National Standard, the Uniform Swimming Pool, Spa and Hot Tub Code (USPSHTC) is a model code developed by the International Association of Plumbing and Mechanical Officials (IAPMO) to govern the installation and inspection of plumbing systems associated with swimming pools, spas and hot tubs as a means of promoting the public's health, safety and welfare.

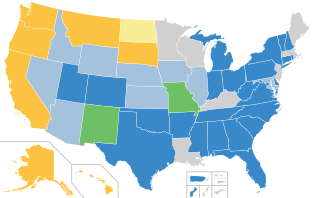

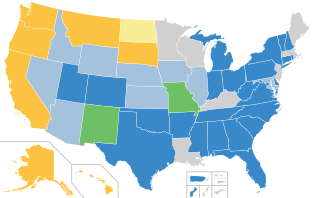

Uniform Codes are codes of practice developed and maintained by the International Association of Plumbing and Mechanical Officials (IAPMO) using the American National Standards Institute's (ANSI) accredited consensus development process working on a three-year cycle. This process brings together volunteers representing a variety of viewpoints and interests to achieve consensus.

Mechanical systems drawing is a type of technical drawing that shows information about heating, ventilating, air conditioning and transportation around the building. It is a powerful tool that helps analyze complex systems. These drawings are often a set of detailed drawings used for construction projects; it is a requirement for all HVAC work. They are based on the floor and reflected ceiling plans of the architect. After the mechanical drawings are complete, they become part of the construction drawings, which is then used to apply for a building permit. They are also used to determine the price of the project.

IAPMO Standards are the plumbing and mechanical standards of the International Association of Plumbing and Mechanical Officials (IAPMO). For more than thirty years, IAPMO’s standards-developing efforts have primarily focused on plumbing product standards. This concentration was primarily due to IAPMO members’ expertise from more than 50 years of writing and updating the Uniform Plumbing Code (UPC). IAPMO is an American National Standards Institute (ANSI)-recognized Standards Development Organization (SDO).

HVAC is a major sub discipline of mechanical engineering. The goal of HVAC design is to balance indoor environmental comfort with other factors such as installation cost, ease of maintenance, and energy efficiency. The discipline of HVAC includes a large number of specialized terms and acronyms, many of which are summarized in this glossary.

IAPMO R&T was started in 1936 as a third-party listing agency specializing in plumbing and mechanical products. IAPMO R&T is accredited to certify products that meet the criteria of the Uniform Plumbing Code, Uniform Mechanical Code, Uniform Solar Energy Code, Uniform Swimming Pool, Spa and Hot Tub Code and other nationally recognized codes and standards in North America.

The International Mechanical Code (IMC) is a convention concentrating on the safety of heating, ventilation, and air conditioning systems. It is published by the International Code Council (ICC) through the governmental consensus process and is updated on a three-year cycle to include the latest advances in technology and safest mechanical practices. The current version of this code is the 2021 edition. The IMC protects public health and safety for all building heating, cooling and ventilation related design, installation and inspection by providing minimum safeguards for people at homes, schools and workplace. Fuel burning appliances, cooling systems, heating systems appliance venting, location and protection of appliances and many other such issues are addressed in the IMC.

The International Association of Plumbing and Mechanical Officials (IAPMO) coordinates the development and adaptation of plumbing, mechanical, swimming pool and solar energy codes to meet the specific needs of individual jurisdictions both in the United States and abroad. IAPMO develops and publishes the Uniform Plumbing Code (UPC); Uniform Mechanical Code (UMC); Uniform Swimming Pool, Spa and Hot Tub Code (USPSHTC); and the Uniform Solar Energy and Hydronics Code (USEHC), which as of 2018 is known as the Uniform Solar, Hydronics and Geothermal Code (USHGC).

Mechanical, electrical and plumbing (MEP) refers to the installation of services which provide a comfortable space for the building occupants. In residential and commercial buildings, these elements are often designed by a specialized MEP engineering firms. The part of Mechanical in the overall MEP system is almost 70% of the total work. MEP's design is important for planning, decision-making, accurate documentation, performance- and cost-estimation, construction, and operating/maintaining the resulting facilities.

Designated as an American National Standard, the Uniform Solar, Hydronics and Geothermal Code (USHGC) is a model code developed by the International Association of Plumbing and Mechanical Officials (IAPMO) to govern the installation and inspection of solar energy, hydronic heating/cooling systems, and geothermal energy systems as a means of promoting the public's health, safety and welfare.

Ductwork airtightness can be defined as the resistance to inward or outward air leakage through the ductwork envelope. This air leakage is driven by differential pressures across the ductwork envelope due to the combined effects of stack and fan operation.