Related Research Articles

Control engineering or control systems engineering is an engineering discipline that deals with control systems, applying control theory to design equipment and systems with desired behaviors in control environments. The discipline of controls overlaps and is usually taught along with electrical engineering and mechanical engineering at many institutions around the world.

Control theory is a field of control engineering and applied mathematics that deals with the control of dynamical systems in engineered processes and machines. The objective is to develop a model or algorithm governing the application of system inputs to drive the system to a desired state, while minimizing any delay, overshoot, or steady-state error and ensuring a level of control stability; often with the aim to achieve a degree of optimality.

Engineering statistics combines engineering and statistics using scientific methods for analyzing data. Engineering statistics involves data concerning manufacturing processes such as: component dimensions, tolerances, type of material, and fabrication process control. There are many methods used in engineering analysis and they are often displayed as histograms to give a visual of the data as opposed to being just numerical. Examples of methods are:

- Design of Experiments (DOE) is a methodology for formulating scientific and engineering problems using statistical models. The protocol specifies a randomization procedure for the experiment and specifies the primary data-analysis, particularly in hypothesis testing. In a secondary analysis, the statistical analyst further examines the data to suggest other questions and to help plan future experiments. In engineering applications, the goal is often to optimize a process or product, rather than to subject a scientific hypothesis to test of its predictive adequacy. The use of optimal designs reduces the cost of experimentation.

- Quality control and process control use statistics as a tool to manage conformance to specifications of manufacturing processes and their products.

- Time and methods engineering use statistics to study repetitive operations in manufacturing in order to set standards and find optimum manufacturing procedures.

- Reliability engineering which measures the ability of a system to perform for its intended function and has tools for improving performance.

- Probabilistic design involving the use of probability in product and system design

- System identification uses statistical methods to build mathematical models of dynamical systems from measured data. System identification also includes the optimal design of experiments for efficiently generating informative data for fitting such models.

A simulation is an imitative representation of a process or system that could exist in the real world. In this broad sense, simulation can often be used interchangeably with model. Sometimes a clear distinction between the two terms is made, in which simulations require the use of models; the model represents the key characteristics or behaviors of the selected system or process, whereas the simulation represents the evolution of the model over time. Another way to distinguish between the terms is to define simulation as experimentation with the help of a model. This definition includes time-independent simulations. Often, computers are used to execute the simulation.

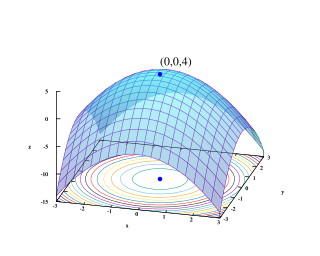

Mathematical optimization or mathematical programming is the selection of a best element, with regard to some criterion, from some set of available alternatives. It is generally divided into two subfields: discrete optimization and continuous optimization. Optimization problems arise in all quantitative disciplines from computer science and engineering to operations research and economics, and the development of solution methods has been of interest in mathematics for centuries.

Usability can be described as the capacity of a system to provide a condition for its users to perform the tasks safely, effectively, and efficiently while enjoying the experience. In software engineering, usability is the degree to which a software can be used by specified consumers to achieve quantified objectives with effectiveness, efficiency, and satisfaction in a quantified context of use.

In computer science, model checking or property checking is a method for checking whether a finite-state model of a system meets a given specification. This is typically associated with hardware or software systems, where the specification contains liveness requirements as well as safety requirements.

Computer simulation is the process of mathematical modelling, performed on a computer, which is designed to predict the behaviour of, or the outcome of, a real-world or physical system. The reliability of some mathematical models can be determined by comparing their results to the real-world outcomes they aim to predict. Computer simulations have become a useful tool for the mathematical modeling of many natural systems in physics, astrophysics, climatology, chemistry, biology and manufacturing, as well as human systems in economics, psychology, social science, health care and engineering. Simulation of a system is represented as the running of the system's model. It can be used to explore and gain new insights into new technology and to estimate the performance of systems too complex for analytical solutions.

The worst-case execution time (WCET) of a computational task is the maximum length of time the task could take to execute on a specific hardware platform.

In biology and other experimental sciences, an in silico experiment is one performed on computer or via computer simulation. The phrase is pseudo-Latin for 'in silicon', referring to silicon in computer chips. It was coined in 1987 as an allusion to the Latin phrases in vivo, in vitro, and in situ, which are commonly used in biology. The latter phrases refer, respectively, to experiments done in living organisms, outside living organisms, and where they are found in nature.

Model predictive control (MPC) is an advanced method of process control that is used to control a process while satisfying a set of constraints. It has been in use in the process industries in chemical plants and oil refineries since the 1980s. In recent years it has also been used in power system balancing models and in power electronics. Model predictive controllers rely on dynamic models of the process, most often linear empirical models obtained by system identification. The main advantage of MPC is the fact that it allows the current timeslot to be optimized, while keeping future timeslots in account. This is achieved by optimizing a finite time-horizon, but only implementing the current timeslot and then optimizing again, repeatedly, thus differing from a linear–quadratic regulator (LQR). Also MPC has the ability to anticipate future events and can take control actions accordingly. PID controllers do not have this predictive ability. MPC is nearly universally implemented as a digital control, although there is research into achieving faster response times with specially designed analog circuitry.

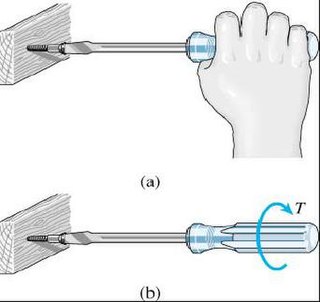

The engineering design process, also known as the engineering method, is a common series of steps that engineers use in creating functional products and processes. The process is highly iterative – parts of the process often need to be repeated many times before another can be entered – though the part(s) that get iterated and the number of such cycles in any given project may vary.

Simulation software is based on the process of modeling a real phenomenon with a set of mathematical formulas. It is, essentially, a program that allows the user to observe an operation through simulation without actually performing that operation. Simulation software is used widely to design equipment so that the final product will be as close to design specs as possible without expensive in process modification. Simulation software with real-time response is often used in gaming, but it also has important industrial applications. When the penalty for improper operation is costly, such as airplane pilots, nuclear power plant operators, or chemical plant operators, a mock up of the actual control panel is connected to a real-time simulation of the physical response, giving valuable training experience without fear of a disastrous outcome.

Model-based design (MBD) is a mathematical and visual method of addressing problems associated with designing complex control, signal processing and communication systems. It is used in many motion control, industrial equipment, aerospace, and automotive applications. Model-based design is a methodology applied in designing embedded software.

Modeling and simulation (M&S) is the use of models as a basis for simulations to develop data utilized for managerial or technical decision making.

OptiY is a design environment software that provides modern optimization strategies and state of the art probabilistic algorithms for uncertainty, reliability, robustness, sensitivity analysis, data-mining and meta-modeling.

TAPAAL is a tool for modelling, simulation and verification of Timed-Arc Petri nets developed at Department of Computer Science at Aalborg University in Denmark and it is available for Linux, Windows and Mac OS X platforms.

PragmaDev Studio is a modeling and testing software tool introduced by PragmaDev in 2002 dedicated to the specification of communicating systems. It was initially called Real Time Developer Studio or RTDS. Its primary objective was to support SDL-RT modeling technology. Since V5.0 launched on October 7, 2015 RTDS is called PragmaDev Studio, and it is organized in four independent modules: Specifier, Developer, Tester and Tracer. V5.1 launched on November 29, 2016 introduces a freemium licensing model.

A virtual human is a software fictional character or human being. Virtual human have been created as tools and artificial companions in simulation, video games, film production, human factors and ergonomic and usability studies in various industries, clothing industry, telecommunications (avatars), medicine, etc. These applications require domain-dependent simulation fidelity. A medical application might require an exact simulation of specific internal organs; film industry requires highest aesthetic standards, natural movements, and facial expressions; ergonomic studies require faithful body proportions for a particular population segment and realistic locomotion with constraints, etc.