A forge is a type of hearth used for heating metals, or the workplace (smithy) where such a hearth is located. The forge is used by the smith to heat a piece of metal to a temperature at which it becomes easier to shape by forging, or to the point at which work hardening no longer occurs. The metal is transported to and from the forge using tongs, which are also used to hold the workpiece on the smithy's anvil while the smith works it with a hammer. Sometimes, such as when hardening steel or cooling the work so that it may be handled with bare hands, the workpiece is transported to the slack tub, which rapidly cools the workpiece in a large body of water. However, depending on the metal type, it may require an oil quench or a salt brine instead; many metals require more than plain water hardening. The slack tub also provides water to control the fire in the forge.

The uilleann pipes, sometimes called Irish Bagpipes, are the characteristic national bagpipe of Ireland. Earlier known in English as "union pipes", their current name is a partial translation of the Irish language terms píobaí uilleann, from their method of inflation. There is no historical record of the name or use of the term uilleann pipes before the 20th century. It was an invention of Grattan Flood and the name stuck. People mistook the term 'union' to refer to the 1800 Act of Union; this is incorrect as Breandán Breathnach points out that a poem published in 1796 uses the term 'union'.

Cast iron is a class of iron–carbon alloys with a carbon content more than 2% and silicon content around 1-3%. Its usefulness derives from its relatively low melting temperature. The alloying elements determine the form in which its carbon appears: white cast iron has its carbon combined into an iron carbide named cementite, which is very hard, but brittle, as it allows cracks to pass straight through; grey cast iron has graphite flakes which deflect a passing crack and initiate countless new cracks as the material breaks, and ductile cast iron has spherical graphite "nodules" which stop the crack from further progressing.

The atmospheric engine was invented by Thomas Newcomen in 1712, and is often referred to as the Newcomen fire engine or simply as a Newcomen engine. The engine was operated by condensing steam drawn into the cylinder, thereby creating a partial vacuum which allowed the atmospheric pressure to push the piston into the cylinder. It was historically significant as the first practical device to harness steam to produce mechanical work. Newcomen engines were used throughout Britain and Europe, principally to pump water out of mines. Hundreds were constructed throughout the 18th century.

A teapot is a vessel used for steeping tea leaves or a herbal mix in boiling or near-boiling water, and for serving the resulting infusion which is called tea. It is one of the core components of teaware. Dry tea is available either in tea bags or as loose tea, in which case a tea infuser or tea strainer may be of some assistance, either to hold the leaves as they steep or to catch the leaves inside the teapot when the tea is poured. Teapots usually have an opening with a lid at their top, where the dry tea and hot water are added, a handle for holding by hand and a spout through which the tea is served. Some teapots have a strainer built-in on the inner edge of the spout. A small air hole in the lid is often created to stop the spout from dripping and splashing when tea is poured. In modern times, a thermally insulating cover called a tea cosy may be used to enhance the steeping process or to prevent the contents of the teapot from cooling too rapidly.

A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally pig iron, but also others such as lead or copper. Blast refers to the combustion air being supplied above atmospheric pressure.

An iron lung is a type of negative pressure ventilator (NPV), a mechanical respirator which encloses most of a person's body, and varies the air pressure in the enclosed space, to stimulate breathing. It assists breathing when muscle control is lost, or the work of breathing exceeds the person's ability. Need for this treatment may result from diseases including polio and botulism and certain poisons.

A bloomery is a type of metallurgical furnace once used widely for smelting iron from its oxides. The bloomery was the earliest form of smelter capable of smelting iron. Bloomeries produce a porous mass of iron and slag called a bloom. The mix of slag and iron in the bloom, termed sponge iron, is usually consolidated and further forged into wrought iron. Blast furnaces, which produce pig iron, have largely superseded bloomeries.

The term blowpipe refers to one of several tools used to direct streams of gases into any of several working media.

An air pump is a pump for pushing air. Examples include a bicycle pump, pumps that are used to aerate an aquarium or a pond via an airstone; a gas compressor used to power a pneumatic tool, air horn or pipe organ; a bellows used to encourage a fire; a vacuum cleaner and a vacuum pump. All air pumps contain a part that moves which drives the flow of air. When the air gets moved, an area of low pressure gets created which fills up with more air.

A silo is a structure for storing bulk materials. Silos are used in agriculture to store fermented feed known as silage, not to be confused with a grain bin, which is used to store grains. Silos are commonly used for bulk storage of grain, coal, cement, carbon black, woodchips, food products and sawdust. Three types of silos are in widespread use today: tower silos, bunker silos, and bag silos.

A fire piston, sometimes called a fire syringe or a slam rod fire starter, is a device of ancient Austroasiatic origin which is used to kindle fire. In Malay it is called "gobek api". It uses the principle of the heating of a gas by rapid and adiabatic compression to ignite a piece of tinder, which is then used to set light to kindling.

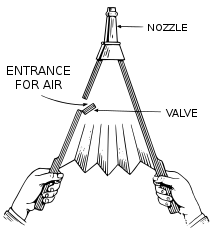

A tuyere or tuyère is a tube, nozzle or pipe through which air is blown into a furnace or hearth.

Pneumatic valve springs are metal bellows filled with compressed air used as an alternative to the metal wire springs used to close valves in high-speed internal combustion engines. This system was introduced in Formula One in 1986 with the Renault EF-Type.

Ferrous metallurgy is the metallurgy of iron and its alloys. The earliest surviving prehistoric iron artifacts, from the 4th millennium BC in Egypt, were made from meteoritic iron-nickel. It is not known when or where the smelting of iron from ores began, but by the end of the 2nd millennium BC iron was being produced from iron ores in the region from Greece to India, and sub-Saharan Africa. The use of wrought iron was known by the 1st millennium BC, and its spread defined the Iron Age. During the medieval period, smiths in Europe found a way of producing wrought iron from cast iron, in this context known as pig iron, using finery forges. All these processes required charcoal as fuel.

In metallurgy, refining consists of purifying an impure metal. It is to be distinguished from other processes such as smelting and calcining in that those two involve a chemical change to the raw material, whereas in refining, the final material is usually identical chemically to the original one, only it is purer. The processes used are of many types, including pyrometallurgical and hydrometallurgical techniques.

Cornwall Iron Furnace is a designated National Historic Landmark that is administered by the Pennsylvania Historical and Museum Commission in Cornwall, Lebanon County, Pennsylvania in the United States. The furnace was a leading Pennsylvania iron producer from 1742 until it was shut down in 1883. The furnaces, support buildings and surrounding community have been preserved as a historical site and museum, providing a glimpse into Lebanon County's industrial past. The site is the only intact charcoal-burning iron blast furnace in its original plantation in the western hemisphere. Established by Peter Grubb in 1742, Cornwall Furnace was operated during the Revolution by his sons Curtis and Peter Jr. who were major arms providers to George Washington. Robert Coleman acquired Cornwall Furnace after the Revolution and became Pennsylvania's first millionaire. Ownership of the furnace and its surroundings was transferred to the Commonwealth of Pennsylvania in 1932.

Du Shi was a Chinese hydrologist, inventor, mechanical engineer, metallurgist, and politician of the Eastern Han Dynasty. Du Shi is credited with being the first to apply hydraulic power to operate bellows in metallurgy. His invention was used to operate piston-bellows of the blast furnace and then cupola furnace in order to forge cast iron, which had been known in China since the 6th century BC. He worked as a censorial officer and administrator of several places during the reign of Emperor Guangwu of Han. He also led a brief military campaign in which he eliminated a small bandit army under Yang Yi.

Titanium-rich scaffold formation is a technical measure used in the blast furnace in order to protect the refractory furnace lining material from erosion by depositing a protection layer over it. It is particularly used to protect the refractory of the blast furnace hearth, located at the bottom of the blast furnace where droplets of melted iron accumulates. The operation is conducted by inserting Ti ore either by injecting it through one or more tuyeres as a powder, or by adding it to the ore together with coke and iron ore from the furnace top.

Kemondo Iron Age Sites or KM2 and KM3 are Early Iron Age complex industrial archaeological sites in Kemondo ward, Bukoba Rural District, Kagera Region, Tanzania, excavated by a team led by archaeologist Peter Schmid in the late 1970s and 1980s. The excavations aimed at better understanding the iron smelting process and its ritual aspects in East Africa. At the KM2 and KM3 sites, Schmidt tested the hypothesis that the high combustion temperature of furnaces, discovered to be between 1,350–1,400 °C (2,460–2,550 °F), was caused by the preheating of air blasts. Preheating has been suggested to be a distinct feature of African Early Iron Age smelting techniques by ethnographic observations of the Haya people of northwestern Tanzania.