Related Research Articles

Filtration is a physical, biological or chemical operation that separates solid matter and fluid from a mixture with a filter medium that has a complex structure through which only the fluid can pass. Solid particles that cannot pass through the filter medium are described as oversize and the fluid that passes through is called the filtrate. Oversize particles may form a filter cake on top of the filter and may also block the filter lattice, preventing the fluid phase from crossing the filter, known as blinding. The size of the largest particles that can successfully pass through a filter is called the effective pore size of that filter. The separation of solid and fluid is imperfect; solids will be contaminated with some fluid and filtrate will contain fine particles. Filtration occurs both in nature and in engineered systems; there are biological, geological, and industrial forms.

Valmet Oyj is a Finnish company and a developer and supplier of technologies, automation systems and services for the pulp, paper and energy industries.

A centrifuge is a piece of equipment that puts an object in rotation around a fixed axis, applying a force perpendicular to the axis of spin (outward) that can be very strong. The centrifuge works using the sedimentation principle, where the centrifugal acceleration causes denser substances and particles to move outward in the radial direction. At the same time, objects that are less dense are displaced and move to the center. In a laboratory centrifuge that uses sample tubes, the radial acceleration causes denser particles to settle to the bottom of the tube, while low-density substances rise to the top.

Baker Hughes Company is an American international industrial service company and one of the world's largest oil field services companies. The company provides the oil and gas industry with products and services for oil drilling, formation evaluation, completion, production and reservoir consulting. Baker Hughes is organized in Delaware and headquartered in Houston. The company was originally known as Baker Hughes Incorporated until 2017 when it was merged with GE Oil and Gas to become Baker Hughes, a GE Company (BHGE), then in 2019 the company divested from General Electric and became Baker Hughes Company. Despite the separation, General Electric still maintains a 38.4% share hold in the company.

A sugar refinery is a refinery which processes raw sugar into white refined sugar or that processes sugar beet to refined sugar.

SDF, a multinational group based in Treviglio (Bergamo) in Italy, and is one of the world's leading manufacturers of tractors, harvesting machines, diesel engines and agricultural machinery. The group's products are commercialised under the brand names SAME, Lamborghini Trattori, Hürlimann, DEUTZ-FAHR and Grégoire. The tractors produced by the group cover a power range from 25 to 336 HP, while its harvesting machines cover a range of powers up to 395 HP.

Deutz-Fahr is a brand of tractors and other farm equipment. It was established in 1968 after the acquisition of the majority of share capital in FAHR, a leading company already producing agricultural equipment in the previous century, by the Klockner-Humboldt-Deutz AG (KHD) group.

An oil filter is a filter designed to remove contaminants from engine oil, transmission oil, lubricating oil, or hydraulic oil. Oil filters are used in many different types of hydraulic machinery. A chief use of the oil filter is in internal-combustion engines in on- and off-road motor vehicles, light aircraft, and various naval vessels. Other vehicle hydraulic systems, such as those in automatic transmissions and power steering, are often equipped with an oil filter. Gas turbine engines, such as those on jet aircraft, also require the use of oil filters. Aside from these uses, oil production, transport, and recycling facilities also employ filters in the manufacturing process.

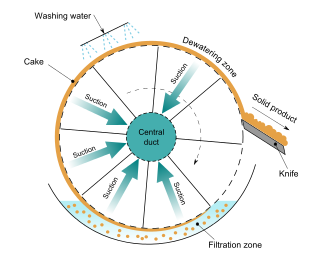

A Rotary Vacuum Filter Drum consists of a drum rotating in a tub of liquid to be filtered.

Bunzl plc is a British multinational distribution and outsourcing company headquartered in London, United Kingdom.

Donaldson Company, Inc. is a vertically integrated filtration company engaged in the production and marketing of air filters used in a variety of industry sectors, including commercial/industrial, aerospace, chemical, alternative energy (windmills) and pharmaceuticals. Also the company's research division, located in Minneapolis, Minn., participated in defense-related projects for various military applications.

Flottweg SE is a manufacturer of machines and systems for mechanical liquid-solid separation. The headquarters is located in Vilsbiburg (Bavaria), Germany. The company develops and produces decanter centrifuges, separators and belt presses. Flottweg has subsidiaries and branch offices with service centers in the United States, People´s Republic of China, Russia, Italy, Poland, France, Australia and Mexico.

KHD Humboldt Wedag is an engineering company that supplies machinery, parts, and services, including process engineering and project management to the global cement industry. The holding company KHD Humboldt Wedag International AG, based in Cologne, Germany employs more than 750 employees worldwide, including customer service centers in the Americas, India, Russia, and the Asia-Pacific region.

A pusher centrifuge is a type of filtration technique that offers continuous operation to de-water and wash materials such as relatively in-compressible feed solids, free-draining crystalline, polymers and fibrous substances. It consists of a constant speed rotor and is fixed to one of several baskets. This assembly is applied with centrifugal force that is generated mechanically for smaller units and hydraulically for larger units to enable separation.

The peeler centrifuge is a device that performs by rotating filtration basket in an axis. A centrifuge follows on the principle of centrifugal force to separate solids from liquids by density difference. High rotation speed provides high centrifugal force that allows the suspended solid in feed to settle on the inner surface of basket. There are three kinds of centrifuge, horizontal, vertical peeler centrifuge and siphon peeler centrifuge. These classes of instrument apply to various areas such as fertilisers, pharmaceutical, plastics and food including artificial sweetener and modified starch.

A centrifuge is a device that employs a high rotational speed to separate components of different densities. This becomes relevant in the majority of industrial jobs where solids, liquids and gases are merged into a single mixture and the separation of these different phases is necessary. A decanter centrifuge separates continuously solid materials from liquids in the slurry, and therefore plays an important role in the wastewater treatment, chemical, oil, and food processing industries. There are several factors that affect the performance of a decanter centrifuge, and some design heuristics to be followed which are dependent upon given applications.

A solid bowl centrifuge is a type of centrifuge that uses the principle of sedimentation. A centrifuge is used to separate a mixture that consists of two substances with different densities by using the centrifugal force resulting from continuous rotation. It is normally used to separate solid-liquid, liquid-liquid, and solid-solid mixtures. Solid bowl centrifuges are widely used in various industrial applications, such as wastewater treatment, coal manufacturing, and polymer manufacturing. One advantage of solid bowl centrifuges for industrial uses is the simplicity of installation compared to other types of centrifuge. There are three design types of solid bowl centrifuge, which are conical, cylindrical, and conical-cylindrical.

A conical plate centrifuge is a type of centrifuge that has a series of conical discs which provides a parallel configuration of centrifugation spaces.

Screen/Scroll centrifuge is a filtering or screen centrifuge which is also known as worm screen or conveyor discharge centrifuge. This centrifuge was first introduced in the midst of 19th century. After developing new technologies over the decades, it is now one of the widely used processes in many industries for the separation of crystalline, granular or fibrous materials from a solid-liquid mixture. Also, this process is considered to dry the solid material. This process has been some of the most frequently seen within, especially, coal preparation industry. Moreover, it can be found in other industries such as chemical, environmental, food and other mining fields.

The Heimbach Group is a supplier of textiles for the paper manufacturing, environmental technology and other industries. Headquartered in Düren, Germany, with production sites located throughout Europe, Heimbach Group produces industrial textiles and filtration materials for various applications.

References

- ↑ Project Historian (unnamed), "7. Applying the Lessons of the Past", PT&P History: The First Thirty-Five Years (2nd ed.), Piping Technology & Products , retrieved August 17, 2012

- ↑ www.andritz.com [ permanent dead link ]

- ↑ www.corporate-ir.net