Coal is a combustible black or brownish-black sedimentary rock, formed as rock strata called coal seams. Coal is mostly carbon with variable amounts of other elements, chiefly hydrogen, sulfur, oxygen, and nitrogen. Coal is a type of fossil fuel, formed when dead plant matter decays into peat and is converted into coal by the heat and pressure of deep burial over millions of years. Vast deposits of coal originate in former wetlands called coal forests that covered much of the Earth's tropical land areas during the late Carboniferous (Pennsylvanian) and Permian times.

Lignite often referred to as brown coal, is a soft, brown, combustible, sedimentary rock formed from naturally compressed peat. It has a carbon content around 25–35%, and is considered the lowest rank of coal due to its relatively low heat content. When removed from the ground, it contains a very high amount of moisture which partially explains its low carbon content. Lignite is mined all around the world and is used almost exclusively as a fuel for steam-electric power generation.

Solid fuel refers to various forms of solid material that can be burnt to release energy, providing heat and light through the process of combustion. Solid fuels can be contrasted with liquid fuels and gaseous fuels. Common examples of solid fuels include wood, charcoal, peat, coal, hexamine fuel tablets, dry dung, wood pellets, corn, wheat, rye, and other grains. Solid fuels are extensively used in rocketry as solid propellants. Solid fuels have been used throughout human history to create fire and solid fuel is still in widespread use throughout the world in the present day.

A briquette is a compressed block of coal dust or other combustible biomass material used for fuel and kindling to start a fire. The term derives from the French word brique, meaning brick.

The heating value of a substance, usually a fuel or food, is the amount of heat released during the combustion of a specified amount of it.

NLC India Limited (NLC) is a central public sector undertaking under the administrative control of the Ministry of Coal, Government of India. It annually produces about 30 million tonnes of lignite from opencast mines at Neyveli in the state of Tamil Nadu in southern India and at Barsingsar in Bikaner district of Rajasthan state. The lignite is used at pithead thermal power stations of 3640 MW installed capacity to produce electricity. Its joint venture has a 1000 MW thermal power station using coal. Lately, it has diversified into renewable energy production and installed 1404 MW solar power plant to produce electricity from photovoltaic (PV) cells and 51 MW electricity from windmills.

Petroleum coke, abbreviated coke, pet coke or petcoke, is a final carbon-rich solid material that derives from oil refining, and is one type of the group of fuels referred to as cokes. Petcoke is the coke that, in particular, derives from a final cracking process—a thermo-based chemical engineering process that splits long chain hydrocarbons of petroleum into shorter chains—that takes place in units termed coker units. Stated succinctly, coke is the "carbonization product of high-boiling hydrocarbon fractions obtained in petroleum processing ". Petcoke is also produced in the production of synthetic crude oil (syncrude) from bitumen extracted from Canada's tar sands and from Venezuela's Orinoco oil sands.

Coal analysis techniques are specific analytical methods designed to measure the particular physical and chemical properties of coals. These methods are used primarily to determine the suitability of coal for coking, power generation or for iron ore smelting in the manufacture of steel.

Coal is mined in every state of Australia. The largest black coal resources occur in Queensland and New South Wales. About 70% of coal mined in Australia is exported, mostly to eastern Asia, and of the balance most is used in electricity generation. In 2019-20 Australia exported 390 Mt of coal and was the world's largest exporter of metallurgical coal and second largest exporter of thermal coal. While only employing 50,000 mining jobs nationally coal provides a rich revenue stream for governments.

Coal mining regions are significant resource extraction industries in many parts of the world. They provide a large amount of the fossil fuel energy in the world economy.

Coal in India has been mined since 1774, and India is the second largest producer and consumer of coal after China, mining 777.31 million metric tons in FY 2022. Around 30% of coal is imported. Due to demand, supply mismatch and poor quality with high ash content, India imports coking coal to meet the shortage of domestic supply. Dhanbad, the largest coal producing city, has been called the coal capital of India. State-owned Coal India had a monopoly on coal mining between its nationalisation in 1973 and 2018.

Refined coal is the product of the coal-upgrading technology that removes moisture and certain pollutants from lower-rank coals such as sub-bituminous and lignite (brown) coals, raising their calorific values. Coal refining or upgrading technologies are typically pre-combustion treatments and processes that alter the characteristics of coal before it is burned. Pre-combustion coal-upgrading technologies aim to increase efficiency and reduce emissions when coal is burned. Depending on the situation, pre-combustion technology can be used in place of or as a supplement to post-combustion technologies to control emissions from coal-fueled boilers. A primary benefit of refined coal is the capacity to reduce the net volume of carbon emissions that is currently emitted from power generators and would reduce the number of emissions that is proposed to be managed via emerging carbon sequestration methodologies. Refined coal technologies have primarily been developed in the United States. Several similar technologies have been researched, developed, and tested in Victoria, Australia, including the Densified coal technology developed to alter the chemical bonds of brown coal to create a product that is cleaner, stable, exportable and of sufficiently high calorific value to be a black coal equivalent.

Torrefaction of biomass, e.g., wood or grain, is a mild form of pyrolysis at temperatures typically between 200 and 320 °C. Torrefaction changes biomass properties to provide a better fuel quality for combustion and gasification applications. Torrefaction produces a relatively dry product, which reduces or eliminates its potential for organic decomposition. Torrefaction combined with densification creates an energy-dense fuel carrier of 20 to 21 GJ/ton lower heating value (LHV). Torrefaction makes the material undergo Maillard reactions. Torrefied biomass can be used as an energy carrier or as a feedstock used in the production of bio-based fuels and chemicals.

The Kemper Project, also called the Kemper County energy facility or Plant Ratcliffe, is a natural gas-fired electrical generating station currently under construction in Kemper County, Mississippi. Mississippi Power, a subsidiary of Southern Company, began construction of the plant in 2010. The initial, coal-fired project was central to President Obama's Climate Plan, as it was to be based on "clean coal" and was being considered for more support from the Congress and the incoming Trump Administration in late 2016. If it had become operational with coal, the Kemper Project would have been a first-of-its-kind electricity plant to employ gasification and carbon capture technologies at this scale.

Maddingley Mine near Bacchus Marsh Railway Station, Victoria, Australia contains a concentration of a particular brown coal (lignite) formation called Leonardite. A relatively high altitude formation, Maddingley brown coal is distinguished as having 60 per cent moisture content and a rich fulvic acid and humic acid content. A declared strategic State mining reserve, the estimated 400 million tonne deposit at Maddingley is the largest of three known deposits of high value Leonardite in the world, the others occurring in Mexico and Germany.

Densified coal is the product of the Coldry Process coal upgrading technology that removes moisture from low-rank coals such as sub-bituminous and lignite/brown coal. The densification process raises the calorific value of low-rank coal to equal or exceed that of many export-grade black coals. Densified coal resulting from the Coldry Process is regarded as a black coal equivalent or replacement for black coal.

Coal in Europe describes the use of coal as an energy fuel in Europe. Coal includes hard coal, black coal, and brown coal.

Elbistan coalfield, also known as Afşin Elbistan Lignite Reserve, is a large lignite coalfield located in the south-east of Turkey in Kahramanmaraş Province. Elbistan is the field with the most coal in Turkey. Kışlaköy coal mine now mines the field. 200 million tons of CO2 were emitted by burning lignite from this field before 2016, and 2.4 billion tons could be emitted in future. The lignite is high in sulfur and moisture, and only has 1,000 to 1,500 kcal/kg, or less than 5 MJ/kg, which is a quarter of typical thermal coal. The coalfield supplies the Afşin-Elbistan power stations.

Subcoal is a fractional substitute for coal or lignite which uses processed paper and plastic waste. The fuel pellets can be used as a secondary energy source in industrial furnaces, such as lime kilns and cement kilns, coal-fired power stations and blast furnaces. Subcoal has a caloric value comparable with lignite. The technology was developed by the Dutch chemical company DSM. A study by CE Delft revealed that for the paper-plastic fraction of household waste, the Subcoal route has a better climate and overall environmental score as compared to the incineration in a waste incineration plant.

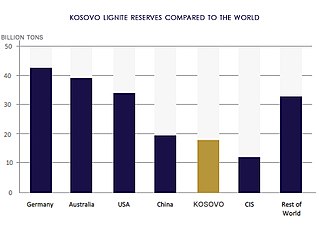

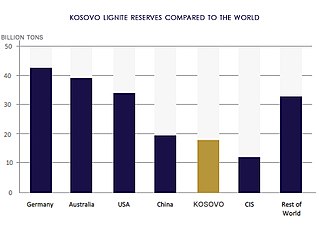

Lignite coal in Kosovo is and will continue to be an important local energy source due to its high reserves. Kosovo is very rich in lignite and accounts around 90% of Kosovo's electricity production. The nation has the 5th largest lignite reserves in the world and the 3rd in Europe. The lignite is distributed across the Kosovo, Dukagjin and Drenica Basins, although mining has so far been restricted to the Kosovo Basin. The lignite is of high quality for the generation of electricity and compares well with the lignite resources of neighbouring countries on a range of parameters. Kosovo's lignite varies in net calorific value from 6.28-9.21 MJ/kg, averaging 7.8 MJ/kg. The deposits can be up to 100 m thick, but average 40 m, and possess an average strip ratio of 1.7:1.