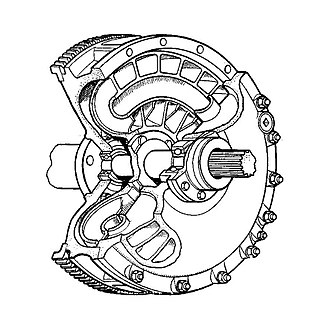

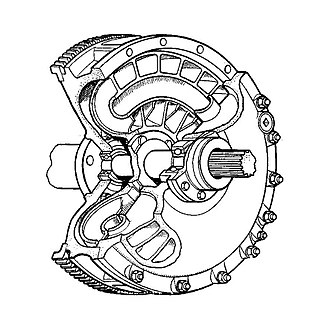

A clutch is a mechanical device that engages and disengages power transmission, especially from a drive shaft to a driven shaft. In the simplest application, clutches connect and disconnect two rotating shafts. In these devices, one shaft is typically attached to an engine and other to power unit, while the other shaft provides output power for work. Typically the motions involved are rotary, but linear clutches also exist.

An automatic transmission is a multi-speed transmission used in internal combustion engine-based motor vehicles that does not require any driver input to change forward gears under normal driving conditions. It typically includes a transmission, axle, and differential in one integrated assembly, thus technically becoming a transaxle.

Propulsion transmission is the mode of transmitting and controlling propulsion power of a machine. The term transmission properly refers to the whole drivetrain, including clutch, gearbox, prop shaft, differential, and final drive shafts. In the United States the term is sometimes used in casual speech to refer more specifically to the gearbox alone, and detailed usage differs. The transmission reduces the higher engine speed to the slower wheel speed, increasing torque in the process. Transmissions are also used on pedal bicycles, fixed machines, and where different rotational speeds and torques are adapted.

A continuously variable transmission (CVT) is an automatic transmission that can change seamlessly through a continuous range of gear ratios. This contrasts with other transmissions that provide a limited number of gear ratios in fixed steps. The flexibility of a CVT with suitable control may allow the engine to operate at a constant RPM while the vehicle moves at varying speeds.

A manual transmission (MT), also known as manual gearbox, standard transmission, or stick shift, is a multi-speed motor vehicle transmission system, where gear changes require the driver to manually select the gears by operating a gear stick and clutch.

A limited-slip differential (LSD) is a type of differential that allows its two output shafts to rotate at different speeds but limits the maximum difference between the two shafts. Limited-slip differentials are often known by the generic trademark Positraction, a brand name owned by General Motors.

Global Hybrid Cooperation, formerly Advanced Hybrid System 2 (AHS2), is a set of hybrid vehicle technologies jointly developed by General Motors, Daimler, and Chrysler LLC, with BMW joining in 2005. It uses 2 or 3 planetary gearsets in an automatic transmission: one on the internal combustion engine (ICE) side paired with a second, forming the compound split, and possibly one third additional planetary gearset to multiply the number of fixed gear ratios. General Motors has stopped using the "AHS2" name as of 2006, preferring to call it simply a two-mode hybrid system.

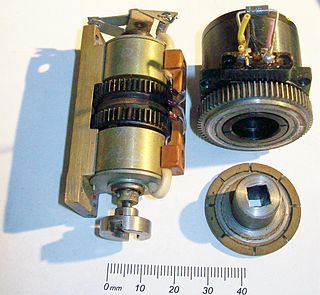

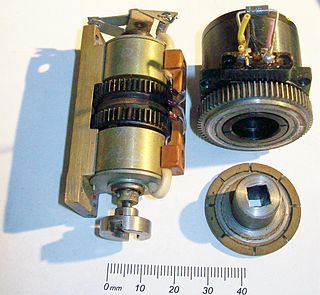

A sprag clutch is a one-way freewheel clutch. It resembles a roller bearing but, instead of cylindrical rollers, non-revolving asymmetric figure-eight shaped sprags, or other elements allowing single direction rotation, are used. When the unit rotates in one direction the rollers slip or free-wheel, but when a torque is applied in the opposite direction, the sprags tilt slightly, producing a wedging action and binding because of friction.

A preselector gearbox is a type of manual transmission mostly used on passenger cars and racing cars in the 1930s, in buses from 1940-1960 and in armoured vehicles from the 1930s to the 1970s. The defining characteristic of a preselector gearbox is that the gear shift lever allowed the driver to "pre-select" the next gear, usually with the transmission remaining in the current gear until the driver pressed the "gear change pedal" at the desired time.

A fluid coupling or hydraulic coupling is a hydrodynamic or 'hydrokinetic' device used to transmit rotating mechanical power. It has been used in automobile transmissions as an alternative to a mechanical clutch. It also has widespread application in marine and industrial machine drives, where variable speed operation and controlled start-up without shock loading of the power transmission system is essential.

A slipper clutch(also known as a back-torque limiter) is a specialized clutch with an integrated freewheel mechanism, developed for performance-oriented motorcycles to mitigate the effects of engine braking when riders decelerate.

Electromagnetic clutches operate electrically but transmit torque mechanically. This is why they used to be referred to as electro-mechanical clutches. Over the years, EM became known as electromagnetic versus electro-mechanical, referring more about their actuation method versus physical operation. Since the clutches started becoming popular over 60 years ago, the variety of applications and clutch designs has increased dramatically, but the basic operation remains the same today.

In engineering, a dog is a tool or part of a tool, such as a pawl, that prevents or imparts movement through physical engagement. It may hold another object in place by blocking it, clamping it, or otherwise obstructing its movement. Or it may couple various parts together so that they move in unison – the primary example of this being a flexible drive to mate two shafts in order to transmit torque. Some devices use dog clutches to lock together two spinning components. In a manual transmission, the dog clutches, or "dogs" lock the selected gear to the shaft it rotates on. Unless the dog is engaged, the gear will simply freewheel on the shaft.

Electromagnetic brakes slow or stop motion using electromagnetic force to apply mechanical resistance (friction). They were originally called "electro-mechanical brakes," but over the years the name changed to "electromagnetic brakes", referring to their actuation method. Since becoming popular in the mid-20th century, especially in trains and trams, the variety of applications and brake designs has increased dramatically, but the basic operation remains the same.

The Ravigneaux gearset is a double planetary gear set, invented by Pol Ravigneaux, who filed a patent application on July 28, 1949, in Neuilly-sur-Seine France. This planetary gear set, commonly used in automatic transmissions, is constructed from two gear pairs, ring–planet and planet–planet.

A jackshaft, also called a countershaft, is a common mechanical design component used to transfer or synchronize rotational force in a machine. A jackshaft is often just a short stub with supporting bearings on the ends and two pulleys, gears, or cranks attached to it. In general, a jackshaft is any shaft that is used as an intermediary transmitting power from a driving shaft to a driven shaft.

In classical mechanics, a reactive centrifugal force forms part of an action–reaction pair with a centripetal force.

Automotive Products, commonly abbreviated to AP, was an automotive industry components company set up in 1920 by Edward Boughton, Willie Emmott and Denis Brock, to import and sell American-made components to service the fleet of ex-military trucks left behind in Europe after World War I.

A dual-clutch transmission (DCT) is a type of multi-speed vehicle transmission system, that uses two separate clutches for odd and even gear sets. The design is often similar to two separate manual transmissions with their respective clutches contained within one housing, and working as one unit. In car and truck applications, the DCT functions as an automatic transmission, requiring no driver input to change gears.

A motorcycle transmission is a transmission created specifically for motorcycle applications. They may also be found in use on other light vehicles such as motor tricycles and quadbikes, go-karts, offroad buggies, auto rickshaws, mowers, and other utility vehicles, microcars, and even some superlight racing cars.