Enterprise resource planning (ERP) is the integrated management of main business processes, often in real time and mediated by software and technology. ERP is usually referred to as a category of business management software—typically a suite of integrated applications—that an organization can use to collect, store, manage and interpret data from many business activities. ERP systems can be local-based or cloud-based. Cloud-based applications have grown in recent years due to the increased efficiencies arising from information being readily available from any location with Internet access.

In telecommunication, provisioning involves the process of preparing and equipping a network to allow it to provide new services to its users. In National Security/Emergency Preparedness telecommunications services, "provisioning" equates to "initiation" and includes altering the state of an existing priority service or capability.

An application program is a computer program designed to carry out a specific task other than one relating to the operation of the computer itself, typically to be used by end-users. Word processors, media players, and accounting software are examples. The collective noun "application software" refers to all applications collectively. The other principal classifications of software are system software, relating to the operation of the computer, and utility software ("utilities").

In industry, product lifecycle management (PLM) is the process of managing the entire lifecycle of a product from its inception through the engineering, design and manufacture, as well as the service and disposal of manufactured products. PLM integrates people, data, processes, and business systems and provides a product information backbone for companies and their extended enterprises.

A computer cluster is a set of computers that work together so that they can be viewed as a single system. Unlike grid computers, computer clusters have each node set to perform the same task, controlled and scheduled by software. The newest manifestation of cluster computing is cloud computing.

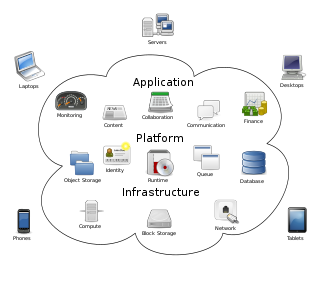

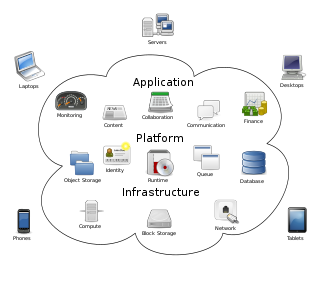

Cloud computing is the on-demand availability of computer system resources, especially data storage and computing power, without direct active management by the user. Large clouds often have functions distributed over multiple locations, each of which is a data center. Cloud computing relies on sharing of resources to achieve coherence and typically uses a pay-as-you-go model, which can help in reducing capital expenses but may also lead to unexpected operating expenses for users.

Converged infrastructure is a way of structuring an information technology (IT) system which groups multiple components into a single optimized computing package. Components of a converged infrastructure may include servers, data storage devices, networking equipment and software for IT infrastructure management, automation and orchestration.

HP Cloud Service Automation is cloud management software from Hewlett Packard Enterprise (HPE) that is used by companies and government agencies to automate the management of cloud-based IT-as-a-service, from order, to provision, and retirement. HP Cloud Service Automation orchestrates the provisioning and deployment of complex IT services such as of databases, middleware, and packaged applications. The software speeds deployment of application-based services across hybrid cloud delivery platforms and traditional IT environments.

HP ConvergedSystem is a portfolio of system-based products from Hewlett-Packard (HP) that integrates preconfigured IT components into systems for virtualization, cloud computing, big data, collaboration, converged management, and client virtualization. Composed of servers, storage, networking, and integrated software and services, the systems are designed to address the cost and complexity of data center operations and maintenance by pulling the IT components together into a single resource pool so they are easier to manage and faster to deploy. Where previously it would take three to six months from the time of order to get a system up and running, it now reportedly takes as few as 20 days with the HP ConvergedSystem.

HP CloudSystem is a cloud infrastructure from Hewlett Packard Enterprise (HPE) that combines storage, servers, networking and software.

openQRM is a free and open-source cloud-computing management platform for managing heterogeneous data centre infrastructures.

HP Cloud was a set of cloud computing services available from Hewlett-Packard. It was the combination of the previous HP Converged Cloud business unit and HP Cloud Services, an OpenStack-based public cloud. It was marketed to enterprise organizations to combine public cloud services with internal IT resources to create hybrid clouds, or a mix of private and public cloud environments, from around 2011 to 2016.

The term Network as a service (NaaS) is often used alongside other marketing terms such as cloud computing It is related to terms like Infrastructure as a Service (IaaS), Platform as a Service (PaaS), Software as a Service (SaaS), and Software-Defined Networking (SDN). and internet exchange points.

Cloud management is the management of cloud computing products and services.

Computation offloading is the transfer of resource intensive computational tasks to a separate processor, such as a hardware accelerator, or an external platform, such as a cluster, grid, or a cloud. Offloading to a coprocessor can be used to accelerate applications including: image rendering and mathematical calculations. Offloading computing to an external platform over a network can provide computing power and overcome hardware limitations of a device, such as limited computational power, storage, and energy.

Cloud-based design and manufacturing (CBDM) refers to a service-oriented networked product development model in which service consumers are able to configure products or services and reconfigure manufacturing systems through Infrastructure-as-a-Service (IaaS), Platform-as-a-Service (PaaS), Hardware-as-a-Service (HaaS), and Software-as-a-Service (SaaS). Adapted from the original cloud computing paradigm and introduced into the realm of computer-aided product development, Cloud-Based Design and Manufacturing is gaining significant momentum and attention from both academia and industry.

Fog computing or fog networking, also known as fogging, is an architecture that uses edge devices to carry out a substantial amount of computation, storage, and communication locally and routed over the Internet backbone.

A digital twin is a digital model of an intended or actual real-world physical product, system, or process that serves as the effectively indistinguishable digital counterpart of it for practical purposes, such as simulation, integration, testing, monitoring, and maintenance. The digital twin is the underlying premise for Product Lifecycle Management and exists throughout the entire lifecycle of the physical entity it represents. Since information is detailed, the digital twin representation is determined by the value-based use cases it is created to implement. The digital twin can exist before the physical entity, as for example with virtual prototyping. The use of a digital twin in the creation phase allows the intended entity's entire lifecycle to be modeled and simulated. A digital twin of an existing entity may be used in real time and regularly synchronized with the corresponding physical system.

Digital manufacturing is an integrated approach to manufacturing that is centered around a computer system. The transition to digital manufacturing has become more popular with the rise in the quantity and quality of computer systems in manufacturing plants. As more automated tools have become used in manufacturing plants it has become necessary to model, simulate, and analyze all of the machines, tooling, and input materials in order to optimize the manufacturing process. Overall, digital manufacturing can be seen sharing the same goals as computer-integrated manufacturing (CIM), flexible manufacturing, lean manufacturing, and design for manufacturability (DFM). The main difference is that digital manufacturing was evolved for use in the computerized world.

Collaborative Control Theory (CCT) is a collection of principles and models for supporting the effective design of collaborative e-Work systems. Beyond human collaboration, advances in information and communications technologies, artificial intelligence, multi-agent systems, and cyber physical systems have enabled cyber-supported collaboration in highly distributed organizations of people, robots, and autonomous systems. The fundamental premise of CCT is: without effective augmented collaboration by cyber support, working in parallel to and in anticipation of human interactions, the potential of emerging activities such as e-Commerce, virtual manufacturing, telerobotics, remote surgery, building automation, smart grids, cyber-physical infrastructure, precision agriculture, and intelligent transportation systems cannot be fully and safely materialized. CCT addresses the challenges and emerging solutions of such cyber-collaborative systems, with emphasis on issues of computer-supported and communication-enabled integration, coordination and augmented collaboration. CCT is composed of eight design principles: (1) Collaboration Requirement Planning (CRP); (2) e-Work Parallelism (EWP); (3) Keep It Simple, System (KISS); (4) Conflict/Error Detection and Prevention (CEDP); (5) Fault Tolerance by Teaming (FTT); (6) Association/Dissociation (AD); (7) Dynamic Lines of Collaboration (DLOC); and (8) Best Matching (BM).