Combined gas and steam (COGAS) is a type of marine compound powerplant comprising gas and steam turbines, the latter being driven by steam generated using the heat from the exhaust of the gas turbines.

Combined gas and steam (COGAS) is a type of marine compound powerplant comprising gas and steam turbines, the latter being driven by steam generated using the heat from the exhaust of the gas turbines.

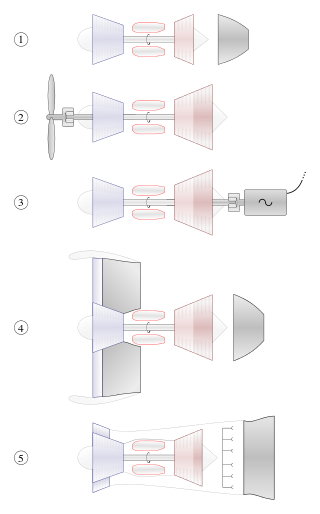

| Combined marine propulsion |

|---|

CODOG |

In this way, some of the otherwise lost energy can be reclaimed and the specific fuel consumption of the plant can be decreased. Large (land-based) electric powerplants built using this combined cycle can reach conversion efficiencies of over 60%. [1]

If the turbines do not drive a propeller shaft directly and instead a turbo-electric transmission is used, the system is known as COGES (combined gas turbine-electric and steam).

COGAS differs from many other combined marine propulsion systems in that it is not intended to operate on one system alone. While this is possible, it will not operate efficiently this way, as with Combined diesel and gas systems when run solely on diesel engines. Especially COGAS should not be confused with Combined steam and gas (COSAG) power plants, which employ traditional, oil-fired boilers for steam turbine propulsion for normal cruising, and supplement this with gas turbines for faster reaction times and higher dash speed.

COGAS has been proposed as upgrade for ships that use gas turbines as their main (or only) engines, e.g. in COGOG or COGAG mode, such as the Arleigh Burke-class destroyers, but currently no naval ship uses this concept. However some modern cruise ships are equipped with COGES. E.g. Celebrity Cruises' Millennium and other ships of her class use turbo-electric plants with two General Electric LM2500+ gas turbines and one steam-turbine.

BMW is currently[ when? ] researching combined gas and steam for automotive use, using their turbosteamer system. This uses the waste heat of combustion from the exhaust and turns it into steam to produce torque which is input into the crankshaft. [ citation needed ]

An engine or motor is a machine designed to convert one or more forms of energy into mechanical energy.

A steam engine is a heat engine that performs mechanical work using steam as its working fluid. The steam engine uses the force produced by steam pressure to push a piston back and forth inside a cylinder. This pushing force can be transformed, by a connecting rod and crank, into rotational force for work. The term "steam engine" is most commonly applied to reciprocating engines as just described, although some authorities have also referred to the steam turbine and devices such as Hero's aeolipile as "steam engines." The essential feature of steam engines is that they are external combustion engines, where the working fluid is separated from the combustion products. The ideal thermodynamic cycle used to analyze this process is called the Rankine cycle. In general usage, the term steam engine can refer to either complete steam plants, such as railway steam locomotives and portable engines, or may refer to the piston or turbine machinery alone, as in the beam engine and stationary steam engine.

A steam turbine is a machine that extracts thermal energy from pressurized steam and uses it to do mechanical work on a rotating output shaft. Its modern manifestation was invented by Charles Parsons in 1884. Fabrication of a modern steam turbine involves advanced metalwork to form high-grade steel alloys into precision parts using technologies that first became available in the 20th century; continued advances in durability and efficiency of steam turbines remains central to the energy economics of the 21st century.

A gas turbine,gas turbine engine, or also known by its old name internal combustion turbine, is a type of continuous flow internal combustion engine. The main parts common to all gas turbine engines form the power-producing part and are, in the direction of flow:

A four-strokeengine is an internal combustion (IC) engine in which the piston completes four separate strokes while turning the crankshaft. A stroke refers to the full travel of the piston along the cylinder, in either direction. The four separate strokes are termed:

A combined cycle power plant is an assembly of heat engines that work in tandem from the same source of heat, converting it into mechanical energy. On land, when used to make electricity the most common type is called a combined cycle gas turbine (CCGT) plant, which is a kind of gas-fired power plant. The same principle is also used for marine propulsion, where it is called a combined gas and steam (COGAS) plant. Combining two or more thermodynamic cycles improves overall efficiency, which reduces fuel costs.

A diesel–electric transmission, or diesel–electric powertrain, is a transmission system for vehicles powered by diesel engines in road, rail, and marine transport. Diesel–electric transmission is based on petrol–electric transmission, a transmission system used for petrol engines.

On a ship, the engine room (ER) is the compartment where the machinery for marine propulsion is located. The engine room is generally the largest physical compartment of the machinery space. It houses the vessel's prime mover, usually some variations of a heat engine. On some ships, there may be more than one engine room, such as forward and aft, or port or starboard engine rooms, or may be simply numbered. To increase a vessel's safety and chances of surviving damage, the machinery necessary for the ship's operation may be segregated into various spaces.

Cogeneration or combined heat and power (CHP) is the use of a heat engine or power station to generate electricity and useful heat at the same time.

Combined diesel and gas (CODAG) is a type of propulsion system for ships that need a maximum speed that is considerably faster than their cruise speed, particularly warships like modern frigates or corvettes.

The General Electric LM2500 is an industrial and marine gas turbine produced by GE Aviation. The LM2500 is a derivative of the General Electric CF6 aircraft engine.

Combined diesel-electric and gas (CODLAG) is a modification of the combined diesel and gas propulsion system for ships. A variant, called the combined diesel-electric or gas (CODLOG) system, contains the same basic elements but will not allow simultaneous use of the alternative drive sources.

A turbosteamer is a term used by BMW to describe a combined cycle engine. Waste heat energy from the internal combustion engine would be used to generate steam for a steam engine which would create supplemental power for the vehicle. The turbosteamer device is affixed to the exhaust and cooling system. It salvages the heat wasted in the exhaust and radiator and uses a steam piston or turbine to relay that power to the crankshaft. The steam circuit produces 14 hp (10 kW) and 15 ft⋅lbf (20 N⋅m) of torque at peak, yielding an estimated 15% gain in fuel efficiency. Unlike gasoline-electric hybrids, these gains increase at higher, steadier speeds.

An inboard motor is a marine propulsion system for boats. As opposed to an outboard motor where an engine is mounted outside the hull of the craft, an inboard motor is an engine enclosed within the hull of the boat, usually connected to a propulsion screw by a driveshaft.

Engine efficiency of thermal engines is the relationship between the total energy contained in the fuel, and the amount of energy used to perform useful work. There are two classifications of thermal engines-

Marine propulsion is the mechanism or system used to generate thrust to move a watercraft through water. While paddles and sails are still used on some smaller boats, most modern ships are propelled by mechanical systems consisting of an electric motor or internal combustion engine driving a propeller, or less frequently, in pump-jets, an impeller. Marine engineering is the discipline concerned with the engineering design process of marine propulsion systems.

MAN Energy Solutions SE is a German multinational company based in Augsburg that produces large-bore gas and diesel engines and also turbomachinery for marine, rail and stationary applications, as locomotive and marine propulsion systems, power plant applications, and turbochargers. The company was formed in 2010 from the merger of MAN Diesel and MAN Turbo. MAN Energy Solutions is a subsidiary of the German carmaker Volkswagen Group.

Integrated electric propulsion (IEP), full electric propulsion (FEP) or integrated full electric propulsion (IFEP) is an arrangement of marine propulsion systems such that gas turbines or diesel generators or both generate three-phase electricity which is then used to power electric motors turning either propellers or waterjet impellors. It is a modification of the combined diesel-electric and gas propulsion system for ships which eliminates the need for clutches and reduces or eliminates the need for gearboxes by using electrical transmission rather than mechanical transmission of energy, so it is a series hybrid electric propulsion, instead of parallel.

An exhaust heat recovery system turns waste heat energy in exhaust gases into electric energy for batteries or mechanical energy reintroduced on the crankshaft. The technology is of increasing interest as car and heavy-duty vehicle manufacturers continue to increase efficiency, saving fuel and reducing emissions.

A turbine–electric transmission system includes a turboshaft gas turbine connected to an electrical generator, creating electricity that powers electric traction motors. No clutch is required.