A fuel pump is a component used in many liquid-fuelled engines to transfer the fuel from the fuel tank to the device where it is mixed with the intake air.

A hydraulic accumulator is a pressure storage reservoir in which an incompressible hydraulic fluid is held under pressure that is applied by an external source of mechanical energy. The external source can be an engine, a spring, a raised weight, or a compressed gas. An accumulator enables a hydraulic system to cope with extremes of demand using a less powerful pump, to respond more quickly to a temporary demand, and to smooth out pulsations. It is a type of energy storage device.

A jackhammer is a pneumatic or electro-mechanical tool that combines a hammer directly with a chisel. It was invented by William McReavy, who then sold the patent to Charles Brady King. Hand-held jackhammers are generally powered by compressed air, but some are also powered by electric motors. Larger jackhammers, such as rig-mounted hammers used on construction machinery, are usually hydraulically powered. These tools are typically used to break up rock, pavement, and concrete.

A concrete mixer is a device that homogeneously combines cement, aggregate, and water to form concrete. A typical concrete mixer uses a revolving drum to mix the components. For smaller volume works, portable concrete mixers are often used so that the concrete can be made at the construction site, giving the workers ample time to use the concrete before it hardens. An alternative to a machine is mixing concrete by hand. This is usually done in a wheelbarrow; however, several companies have recently begun to sell modified tarps for this purpose.

Hydraulic machines use liquid fluid power to perform work. Heavy construction vehicles are a common example. In this type of machine, hydraulic fluid is pumped to various hydraulic motors and hydraulic cylinders throughout the machine and becomes pressurized according to the resistance present. The fluid is controlled directly or automatically by control valves and distributed through hoses, tubes, or pipes.

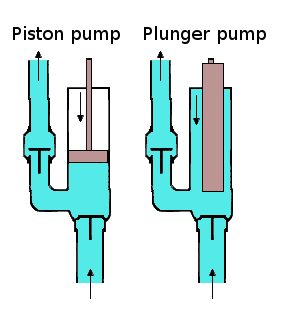

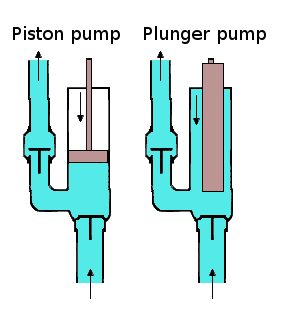

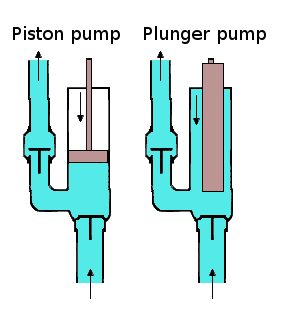

A piston pump is a type of positive displacement pump where the high-pressure seal reciprocates with the piston. Piston pumps can be used to move liquids or compress gases. They can operate over a wide range of pressures. High pressure operation can be achieved without adversely affecting flow rate. Piston pumps can also deal with viscous media and media containing solid particles. This pump type functions through a piston cup, oscillation mechanism where down-strokes cause pressure differentials, filling of pump chambers, where up-stroke forces the pump fluid out for use. Piston pumps are often used in scenarios requiring high, consistent pressure and in water irrigation or delivery systems.

A hydraulic brake is an arrangement of braking mechanism which uses brake fluid, typically containing glycol ethers or diethylene glycol, to transfer pressure from the controlling mechanism to the braking mechanism.

A hydraulic cylinder is a mechanical actuator that is used to give a unidirectional force through a unidirectional stroke. It has many applications, notably in construction equipment, manufacturing machinery, elevators, and civil engineering. A hydraulic cylinder is a hydraulic actuator that provides linear motion when hydraulic energy is converted into mechanical movement. It can be likened to a muscle in that, when the hydraulic system of a machine is activated, the cylinder is responsible for providing the motion.

An axial piston pump is a positive displacement pump that has a number of pistons in a circular array within a cylinder block.

A pile driver is a heavy-duty tool used to drive piles into soil to build piers, bridges, cofferdams, and other "pole" supported structures, and patterns of pilings as part of permanent deep foundations for buildings or other structures. Pilings may be made of wood, solid steel, or tubular steel, and may be driven entirely underwater/underground, or remain partially aboveground as elements of a finished structure.

A metering pump moves a precise volume of liquid in a specified time period providing an accurate volumetric flow rate. Delivery of fluids in precise adjustable flow rates is sometimes called metering. The term "metering pump" is based on the application or use rather than the exact kind of pump used, although a couple types of pumps are far more suitable than most other types of pumps.

A hydraulic motor is a mechanical actuator that converts hydraulic pressure and flow into torque and angular displacement (rotation). The hydraulic motor is the rotary counterpart of the hydraulic cylinder as a linear actuator. Most broadly, the category of devices called hydraulic motors has sometimes included those that run on hydropower but in today's terminology the name usually refers more specifically to motors that use hydraulic fluid as part of closed hydraulic circuits in modern hydraulic machinery.

The Meillerwagen was a German World War II trailer used to transport a V-2 rocket from the 'transloading point' of the Technical Troop Area to the launching point, to erect the missile on the Brennstand, and to act as the service gantry for fuelling and launch preparation.

A plunger pump is a type of positive displacement pump where the high-pressure seal is stationary and a smooth cylindrical plunger slides through the seal. This makes them different from piston pumps and allows them to be used at higher pressures. This type of pump is often used to transfer municipal and industrial sewage.

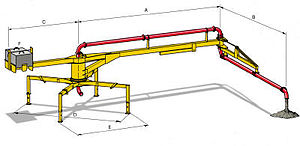

Putzmeister is a German manufacturer of concrete pumps and other equipment for pumping, distributing and placing concrete, mortar and other high-density solids, and for preparing, temporarily storing, processing and transporting these materials. The firm is headquartered at Aichtal, and is the largest in its field. It also provides pumps for a wide range of different materials, for example slurries, fly ash, sewage, compost and water.

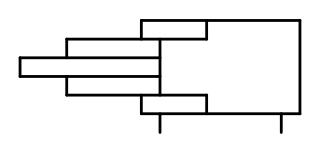

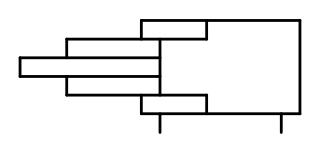

Telescopic cylinders are a special design of a hydraulic cylinder or pneumatic cylinder as well as pulley system which provide an exceptionally long output travel from a very compact retracted length. Typically the collapsed length of a telescopic cylinder is 20 to 40% of the fully extended length depending on the number of stages. Some pneumatic telescoping units are manufactured with retracted lengths of under 15% of overall extended unit length. This feature is very attractive to machine design engineers when a conventional single stage rod style actuator will not fit in an application to produce the required output stroke.

A hydraulic intensifier is a hydraulic machine for transforming hydraulic power at low pressure into a reduced volume at higher pressure.

High-density solids pumps are hydrostatically operating machines which displace the medium being pumped and thus create a flow.

A booster pump is a machine which increases the pressure of a fluid. It may be used with liquids or gases, and the construction details vary depending on the fluid. A gas booster is similar to a gas compressor, but generally a simpler mechanism which often has only a single stage of compression, and is used to increase pressure of a gas already above ambient pressure. Two-stage boosters are also made. Boosters may be used for increasing gas pressure, transferring high pressure gas, charging gas cylinders and scavenging.