The Domino is a loose mortise and tenon joining tool manufactured by the German company Festool.

The Domino is a loose mortise and tenon joining tool manufactured by the German company Festool.

First introduced in 2005, it came to the US market in 2007. [1]

The core idea for this type of a tool came from German master cabinetmaker Vitus Rommel. [2] [3] It envisioned a tool that can cut a mortise in single operation - putting it on par with a biscuit joiner on speed while allowing for a more flexible and potentially stronger floating-tenon joint.

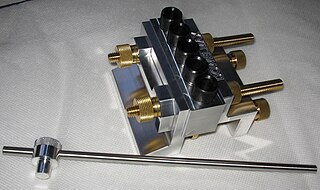

The tool implementation by Festool involves a router-like spinning shaft with a special shape cutter bit. The shaft also moves sideways, allowing to cut full round-ended mortises in a single operation. [1] Each plunge creates a mortise that is sized to accept a standard 'DOMINO' loose tenon with an oval-shaped cross section.

The original tool supported cutter sizes from 4 mm to 10 mm with available tenon sizes from 4x20 mm up to 10x50 mm. This allowed joints in stock as thin as 10 millimetres (0.39 in). Later a bigger tool was introduced allowing tenon sizes up to 14x140 mm, opening many carpentry use cases for the tool family.

The tool series was envisioned from the beginning for high workflow efficiency, namely:

The compactness of a hand-operated tool coupled with the focus on workflow efficiency is what allows the DOMINO mortising tools to service most use cases serve by the simpler tools for 'biscuit' and dowel joints expanding loose-tenon use cases significantly.

In smaller businesses or with the DIY users, where industrial machinery is not available, a cabinetmaker may employ a DOMINO loose-tenon joint where other, less complicated but more laborious, joints would have to be employed otherwise.

The router is a power tool with a flat base and a rotating blade extending past the base. The spindle may be driven by an electric motor or by a pneumatic motor. It routs an area in hard material, such as wood or plastic. Routers are used most often in woodworking, especially cabinetry. They may be handheld or affixed to router tables. Some woodworkers consider the router one of the most versatile power tools.

Joinery is a part of woodworking that involves joining pieces of wood, engineered lumber, or synthetic substitutes, to produce more complex items. Some woodworking joints employ mechanical fasteners, bindings, or adhesives, while others use only wood elements.

Carpentry is a skilled trade and a craft in which the primary work performed is the cutting, shaping and installation of building materials during the construction of buildings, ships, timber bridges, concrete formwork, etc. Carpenters traditionally worked with natural wood and did rougher work such as framing, but today many other materials are also used and sometimes the finer trades of cabinetmaking and furniture building are considered carpentry. In the United States, 98.5% of carpenters are male, and it was the fourth most male-dominated occupation in the country in 1999. In 2006 in the United States, there were about 1.5 million carpentry positions. Carpenters are usually the first tradesmen on a job and the last to leave. Carpenters normally framed post-and-beam buildings until the end of the 19th century; now this old-fashioned carpentry is called timber framing. Carpenters learn this trade by being employed through an apprenticeship training—normally four years—and qualify by successfully completing that country's competence test in places such as the United Kingdom, the United States, Canada, Switzerland, Australia and South Africa. It is also common that the skill can be learned by gaining work experience other than a formal training program, which may be the case in many places.

A mortiseand tenon joint connects two pieces of wood or other material. Woodworkers around the world have used it for thousands of years to join pieces of wood, mainly when the adjoining pieces connect at right angles.

A Woodworking machine is a machine that is intended to process wood. These machines are usually powered by electric motors and are used extensively in woodworking. Sometimes grinding machines are also considered a part of woodworking machinery.

A hand plane is a tool for shaping wood using muscle power to force the cutting blade over the wood surface. Some rotary power planers are motorized power tools used for the same types of larger tasks, but are unsuitable for fine-scale planing, where a miniature hand plane is used.

The Japanese saw or nokogiri (鋸) is a type of saw used in woodworking and Japanese carpentry that cuts on the pull stroke, unlike most European saws that cut on the push stroke. Japanese saws are the best known pull saws, but they are also used in China, Iran, Iraq, Korea, Nepal and Turkey. Among European saws, both coping saws for woodworking and jeweler's saws for metal working also cut on the pull stroke like Japanese saws. Cutting on the pull stroke is claimed to cut more efficiently and leave a narrower cut width. On the other hand, a pull stroke does not easily permit putting one's body weight behind a stroke. This can be readily solved by using a vice or clamping. Another disadvantage, due to the arrangement and form of the teeth, is that Japanese saws do not work as well on hardwoods as European saws do. Japanese saws were originally intended for comparatively soft woods like cypress and pine whereas European saws were intended for hard woods like oak and maple.

A biscuit joiner or biscuit jointer is a woodworking tool used to join two pieces of wood together. A biscuit joiner uses a small circular saw blade to cut a crescent-shaped hole in the opposite edges of two pieces of wood or wood composite panels. An oval-shaped, highly dried and compressed wooden biscuit is covered with glue, or glue is applied in the slot. The biscuit is immediately placed in the slot, and the two boards are clamped together. The wet glue expands the biscuit, further improving the bond.

A mortiser or morticer is a specialized woodworking machine used to cut square or rectangular holes in a piece of lumber (timber), such as a mortise in a mortise and tenon joint.

A backsaw is any hand saw which has a stiffening rib on the edge opposite the cutting edge, enabling better control and more precise cutting than with other types of saws. Backsaws are normally used in woodworking for precise work, such as cutting dovetails, mitres, or tenons in cabinetry and joinery. Because of the stiffening rib, backsaws are limited in the depth to which they can cut. Backsaws usually have relatively closely spaced teeth, often with little or no set.

A wood shaper, is a stationary woodworking machine in which a vertically oriented spindle drives one or more stacked cutter heads to mill profiles on wood stock.

Frame and panel construction, also called rail and stile, is a woodworking technique often used in the making of doors, wainscoting, and other decorative features for cabinets, furniture, and homes. The basic idea is to capture a 'floating' panel within a sturdy frame, as opposed to techniques used in making a slab solid wood cabinet door or drawer front, the door is constructed of several solid wood pieces running in a vertical or horizontal direction with exposed endgrains. Usually, the panel is not glued to the frame but is left to 'float' within it so that seasonal movement of the wood comprising the panel does not distort the frame.

A butt joint is a wood joint in which the end of a piece of material is simply placed against another piece. The butt joint is the simplest joint. An unreinforced butt joint is also the weakest joint, as it provides a limited surface area for gluing and lacks any mechanical interlocking to resist external forces.

Pocket-hole joinery, or pocket-screw joinery, involves drilling a hole at an angle — usually 15 degrees — into one work piece, and then joining it to a second work piece with a self-tapping screw.

This glossary of woodworking lists a number of specialized terms and concepts used in woodworking, carpentry, and related disciplines.

The Dowelmax is a loose tenon dowelling jig manufactured by the O.M.S. Tool company in Canada. The manufacturer claims that the small manufacturing tolerances of 0.026 millimetres (0.0010 in) for the aluminium, brass and steel components of the jig ensure accuracy and repeatability. The precision manufacturing adds to the unit's cost, which is higher than other dowelling jigs.

Hammer-headed tenon joints are one method that can be used to join curved members of joinery components.

A mortise gauge or mortice gauge is a woodworking tool used by a carpenter or joiner to scribe mortise and tenon joints on wood prior to cutting. Mortise gauges are commonly made of hardwood with brass fittings.

A plunge saw or plunge-cut saw is a type of hand-held circular saw which differs from a regular circular saw in that it can plunge into the material to a predetermined depth during the cut. In other words, the depth-of-cut is not fixed and often can be adjusted to be just slightly over the thickness of the board being cut. This property also allows a plunge saw to cut shallow grooves into the workpiece, if necessary. Compared to traditional hand-held circular saws, plunge saws are said to increase operator safety, as well as allowing for reduced splintering and tear-out. Plunge saws are an essential power tool for joiners, carpenters, kitchen fitters and anyone who works with laminates, insulation or needs to make lots of cuts in small work pieces.