Stainless steel, also known as inox, corrosion-resistant steel (CRES) and rustless steel, is an alloy of iron that is resistant to rusting and corrosion. It contains iron with chromium and other elements such as molybdenum, carbon, nickel and nitrogen depending on its specific use and cost. Stainless steel's resistance to corrosion results from the 10.5%, or more, chromium content which forms a passive film that can protect the material and self-heal in the presence of oxygen.

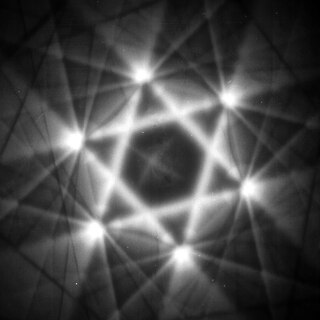

Martensitic stainless steel is a type of stainless steel alloy that has a martensite crystal structure. It can be hardened and tempered through aging and heat treatment. The other main types of stainless steel are austenitic, ferritic, duplex, and precipitation hardened.

Carbon steel is a steel with carbon content from about 0.05 up to 2.1 percent by weight. The definition of carbon steel from the American Iron and Steel Institute (AISI) states:

Maraging steels are steels that are known for possessing superior strength and toughness without losing ductility. Aging refers to the extended heat-treatment process. These steels are a special class of very-low-carbon ultra-high-strength steels that derive their strength not from carbon, but from precipitation of intermetallic compounds. The principal alloying element is 15 to 25 wt% nickel. Secondary alloying elements, which include cobalt, molybdenum and titanium, are added to produce intermetallic precipitates. Original development was carried out on 20 and 25 wt% Ni steels to which small additions of aluminium, titanium, and niobium were made; a rise in the price of cobalt in the late 1970s led to the development of cobalt-free maraging steels.

Titanium alloys are alloys that contain a mixture of titanium and other chemical elements. Such alloys have very high tensile strength and toughness. They are light in weight, have extraordinary corrosion resistance and the ability to withstand extreme temperatures. However, the high cost of both raw materials and processing limit their use to military applications, aircraft, spacecraft, bicycles, medical devices, jewelry, highly stressed components such as connecting rods on expensive sports cars and some premium sports equipment and consumer electronics.

A superalloy, or high-performance alloy, is an alloy with the ability to operate at a high fraction of its melting point. Key characteristics of a superalloy include mechanical strength, thermal creep deformation resistance, surface stability, and corrosion and oxidation resistance.

Marine grade stainless alloys typically contain molybdenum to resist the corrosive effects of NaCl or salt in seawater. Concentrations of salt in seawater can vary, and splash zones can cause concentrations to increase dramatically from the spray and evaporation.

In materials science, intergranular corrosion (IGC), also known as intergranular attack (IGA), is a form of corrosion where the boundaries of crystallites of the material are more susceptible to corrosion than their insides.

Austenitic stainless steel is one of the five classes of stainless steel by crystalline structure. Its primary crystalline structure is austenite and it prevents steels from being hardenable by heat treatment and makes them essentially non-magnetic. This structure is achieved by adding enough austenite-stabilizing elements such as nickel, manganese and nitrogen. The Incoloy family of alloys belong to the category of super austenitic stainless steels.

Embrittlement is a significant decrease of ductility of a material, which makes the material brittle. Embrittlement is used to describe any phenomena where the environment compromises a stressed material's mechanical performance, such as temperature or environmental composition. This is oftentimes undesirable as brittle fracture occurs quicker and can much more easily propagate than ductile fracture, leading to complete failure of the equipment. Various materials have different mechanisms of embrittlement, therefore it can manifest in a variety of ways, from slow crack growth to a reduction of tensile ductility and toughness.

The SAE steel grades system is a standard alloy numbering system for steel grades maintained by SAE International.

Alloy steel is steel that is alloyed with a variety of elements in total amounts between 1.0% and 50% by weight to improve its mechanical properties.

Nickel aluminide refers to either of two widely used intermetallic compounds, Ni3Al or NiAl, but the term is sometimes used to refer to any nickel–aluminium alloy. These alloys are widely used because of their high strength even at high temperature, low density, corrosion resistance, and ease of production. Ni3Al is of specific interest as a precipitate in nickel-based superalloys, where it is called the γ' (gamma prime) phase. It gives these alloys high strength and creep resistance up to 0.7–0.8 of its melting temperature. Meanwhile, NiAl displays excellent properties such as lower density and higher melting temperature than those of Ni3Al, and good thermal conductivity and oxidation resistance. These properties make it attractive for special high-temperature applications like coatings on blades in gas turbines and jet engines. However, both these alloys have the disadvantage of being quite brittle at room temperature, with Ni3Al remaining brittle at high temperatures as well. To address this problem, has been shown that Ni3Al can be made ductile when manufactured in single-crystal form rather than in polycrystalline form.

Zeron 100 is a super duplex stainless steel developed by Rolled Alloys. The alloy has excellent corrosion resistance combined with high strength. It typically contains 25% chromium and 7% nickel and 3.6% molybdenum along with copper and tungsten additions. Zeron 100 has a 50–50 austenitic–ferritic structure. It also has greater resistance to chloride pitting, crevice corrosion and stress corrosion cracking than exhibited by the standard 300 series stainless steels.

SAF 2205, is a Alleima-owned trademark for a 22Cr duplex (ferritic-austenitic) stainless steel. SAF derives from Sandvik Austenite Ferrite. The nominal chemical composition of SAF 2205 is 22% chromium, 5% nickel, 3.2% molybdenum and other alloying elements such as nitrogen and manganese. The UNS designation for SAF 2205 is S31803/S32205 and the EN steel no. is 1.4462. SAF 2205 or Duplex 2205 is often used as an alternative to expensive 904L stainless steel owing to similar properties but cheaper ingredients. Duplex stainless steel is available in multiple forms like bars, billets, pipes, tubes, sheets, plates and even processed to fittings and flanges.

SAF 2507, is a Alleima-owned trademark for a 25Cr duplex (ferritic-austenitic) stainless steel. The nominal chemical composition of SAF 2507 is 25% chromium, 7% nickel, 4% molybdenum and other alloying elements such as nitrogen and manganese. The UNS designation for SAF 2507 is S32750 and the EN steel no. is 1.4410. SAF derives from Sandvik Austenite Ferrite.

SAE 316L grade stainless steel, sometimes referred to as A4 stainless steel or marine grade stainless steel, is the second most common austenitic stainless steel after 304/A2 stainless steel. Its primary alloying constituents after iron, are chromium, nickel (10–12%) and molybdenum (2–3%), with small (<1%) quantities of silicon, phosphorus & sulfur also present. The addition of molybdenum provides greater corrosion resistance than 304, with respect to localized corrosive attack by chlorides and to general corrosion by reducing acids, such as sulfuric acid. 316L grade is the low carbon version of 316 stainless steel. When cold worked, 316 can produce high yield and tensile strengths similar to Duplex stainless grades.

Ferritic stainless steel forms one of the five stainless steel families, the other four being austenitic, martensitic, duplex stainless steels, and precipitation hardened. For example, many of AISI 400-series of stainless steels are ferritic steels. By comparison with austenitic types, these are less hardenable by cold working, less weldable, and should not be used at cryogenic temperatures. Some types, like the 430, have excellent corrosion resistance and are very heat tolerant.

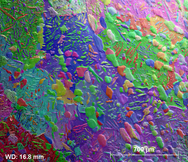

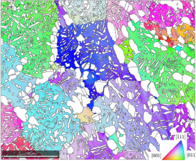

Duplex stainless steels are a family of alloys with a two-phase microstructure consisting of both austenitic and ferritic phases. They offer excellent mechanical properties, corrosion resistance, and toughness compared to other types of stainless steel. However, duplex stainless steel can be susceptible to a phenomenon known as 475 °C (887 °F) embrittlement or duplex stainless steel age hardening, which is a type of aging process that causes loss of plasticity in duplex stainless steel when it is heated in the range of 250 to 550 °C. At this temperature range, spontaneous phase separation of the ferrite phase into iron-rich and chromium-rich nanophases occurs, with no change in the mechanical properties of the austenite phase. This type of embrittlement is due to precipitation hardening, which makes the material become brittle and prone to cracking.