Related Research Articles

Natural gas is a naturally occurring mixture of gaseous hydrocarbons consisting primarily of methane in addition to various smaller amounts of other higher alkanes. Low levels of trace gases like carbon dioxide, nitrogen, hydrogen sulfide, and helium are also usually present. Methane is colorless and odorless, so odorizers such as mercaptan are commonly added to natural gas supplies for safety so that leaks can be readily detected.

Methane clathrate (CH4·5.75H2O) or (8CH4·46H2O), also called methane hydrate, hydromethane, methane ice, fire ice, natural gas hydrate, or gas hydrate, is a solid clathrate compound (more specifically, a clathrate hydrate) in which a large amount of methane is trapped within a crystal structure of water, forming a solid similar to ice. Originally thought to occur only in the outer regions of the Solar System, where temperatures are low and water ice is common, significant deposits of methane clathrate have been found under sediments on the ocean floors of the Earth. Methane hydrate is formed when hydrogen-bonded water and methane gas come into contact at high pressures and low temperatures in oceans.

Clathrate hydrates, or gas hydrates, clathrates, hydrates, etc., are crystalline water-based solids physically resembling ice, in which small non-polar molecules or polar molecules with large hydrophobic moieties are trapped inside "cages" of hydrogen bonded, frozen water molecules. In other words, clathrate hydrates are clathrate compounds in which the host molecule is water and the guest molecule is typically a gas or liquid. Without the support of the trapped molecules, the lattice structure of hydrate clathrates would collapse into conventional ice crystal structure or liquid water. Most low molecular weight gases, including O2, H2, N2, CO2, CH4, H2S, Ar, Kr, and Xe, as well as some higher hydrocarbons and freons, will form hydrates at suitable temperatures and pressures. Clathrate hydrates are not officially chemical compounds, as the enclathrated guest molecules are never bonded to the lattice. The formation and decomposition of clathrate hydrates are first order phase transitions, not chemical reactions. Their detailed formation and decomposition mechanisms on a molecular level are still not well understood. Clathrate hydrates were first documented in 1810 by Sir Humphry Davy who found that water was a primary component of what was earlier thought to be solidified chlorine.

Kerogen is solid, insoluble organic matter in sedimentary rocks. It consists of a variety of organic materials, including dead plants, algae, and other microorganisms, that have been compressed and heated by geological processes. Altogether kerogen is estimated to contain 1016 tons of carbon. This makes it the most abundant source of organic compounds on earth, exceeding the total organic content of living matter 10,000-fold.

Oil sands, tar sands, crude bitumen, or bituminous sands, are a type of unconventional petroleum deposit. Oil sands are either loose sands or partially consolidated sandstone containing a naturally occurring mixture of sand, clay, and water, soaked with bitumen, a dense and extremely viscous form of petroleum.

Crystallization is the process by which solid forms, where the atoms or molecules are highly organized into a structure known as a crystal. Some ways by which crystals form are precipitating from a solution, freezing, or more rarely deposition directly from a gas. Attributes of the resulting crystal depend largely on factors such as temperature, air pressure, and in the case of liquid crystals, time of fluid evaporation.

A petroleum reservoir or oil and gas reservoir is a subsurface accumulation of hydrocarbons contained in porous or fractured rock formations.

In geotechnical engineering, drilling fluid, also called drilling mud, is used to aid the drilling of boreholes into the earth. Often used while drilling oil and natural gas wells and on exploration drilling rigs, drilling fluids are also used for much simpler boreholes, such as water wells. One of the functions of drilling mud is to carry cuttings out of the hole.

Carbon capture and storage (CCS), is a process in which a relatively pure stream of carbon dioxide (CO2) from industrial sources is separated, treated and transported to a long-term storage location. For example, the carbon dioxide stream that is to be captured can result from burning fossil fuels or biomass. Usually the CO2 is captured from large point sources, such as a chemical plant or biomass plant, and then stored in an underground geological formation. The aim is to reduce greenhouse gas emissions and thus mitigate climate change.

Carbon dioxide hydrate or carbon dioxide clathrate is a snow-like crystalline substance composed of water ice and carbon dioxide. It normally is a Type I gas clathrate. There has also been some experimental evidence for the development of a metastable Type II phase at a temperature near the ice melting point. The clathrate can exist below 283K (10 °C) at a range of pressures of carbon dioxide. CO2 hydrates are widely studied around the world due to their promising prospects of carbon dioxide capture from flue gas and fuel gas streams relevant to post-combustion and pre-combustion capture. It is also quite likely to be important on Mars due to the presence of carbon dioxide and ice at low temperatures.

Natural-gas processing is a range of industrial processes designed to purify raw natural gas by removing contaminants such as solids, water, carbon dioxide (CO2), hydrogen sulfide (H2S), mercury and higher molecular mass hydrocarbons (condensate) to produce pipeline quality dry natural gas for pipeline distribution and final use. Some of the substances which contaminate natural gas have economic value and are further processed or sold. Hydrocarbons that are liquid at ambient conditions: temperature and pressure (i.e., pentane and heavier) are called natural-gas condensate (sometimes also called natural gasoline or simply condensate).

Subsea technology involves fully submerged ocean equipment, operations, or applications, especially when some distance offshore, in deep ocean waters, or on the seabed. The term subsea is frequently used in connection with oceanography, marine or ocean engineering, ocean exploration, remotely operated vehicle (ROVs) autonomous underwater vehicles (AUVs), submarine communications or power cables, seafloor mineral mining, oil and gas, and offshore wind power.

An oil production plant is a facility which processes production fluids from oil wells in order to separate out key components and prepare them for export. Typical oil well production fluids are a mixture of oil, gas and produced water. An oil production plant is distinct from an oil depot, which does not have processing facilities.

The Sleipner gas field is a natural gas field in the block 15/9 of the North Sea, about 250 kilometres (160 mi) west of Stavanger, Norway. Two parts of the field are in production, Sleipner West, and Sleipner East (1981). The field produces natural gas and light oil condensates from sandstone structures about 2,500 metres (8,200 ft) below sea level. It is operated by Equinor. The field is named after the steed Sleipnir in Norse mythology.

The Mallik Methane Hydrate Site is located in the Beaufort Sea, Canada.

Nankai Methane Hydrate Site is located in the Nankai Trough, Japan.

In the petroleum industry, allocation refers to practices of breaking down measures of quantities of extracted hydrocarbons across various contributing sources. Allocation aids the attribution of ownerships of hydrocarbons as each contributing element to a commingled flow or to a storage of petroleum may have a unique ownership. Contributing sources in this context are typically producing petroleum wells delivering flows of petroleum or flows of natural gas to a commingled flow or storage.

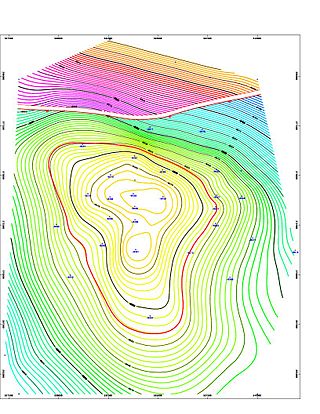

Gas hydrate stability zone, abbreviated GHSZ, also referred to as methane hydrate stability zone (MHSZ) or hydrate stability zone (HSZ), refers to a zone and depth of the marine environment at which methane clathrates naturally exist in the Earth's crust.

Oilfield scale inhibition is the process of preventing the formation of scale from blocking or hindering fluid flow through pipelines, valves, and pumps used in oil production and processing. Scale inhibitors (SIs) are a class of specialty chemicals that are used to slow or prevent scaling in water systems. Oilfield scaling is the precipitation and accumulation of insoluble crystals (salts) from a mixture of incompatible aqueous phases in oil processing systems. Scale is a common term in the oil industry used to describe solid deposits that grow over time, blocking and hindering fluid flow through pipelines, valves, pumps etc. with significant reduction in production rates and equipment damages. Scaling represents a major challenge for flow assurance in the oil and gas industry. Examples of oilfield scales are calcium carbonate (limescale), iron sulfides, barium sulfate and strontium sulfate. Scale inhibition encompasses the processes or techniques employed to treat scaling problems.

Wax or paraffin deposition refers to the accumulation of paraffin wax on the surface of a substance, typically a liquid or gas. This can occur in a variety of contexts, including the production and transport of oil and natural gas, the refining of petroleum products, and the storage and transport of chemicals. For the transportation of crude oil in a pipeline, wax can deposit on to the inner surface of the pipeline, reducing the area for fluid to flow and increasing the pressure requirement for fluid to flow. To prevent wax deposition, various techniques can be used, including heating the fluid to dissolve wax back into the oil phase, adding chemicals to prevent wax formation, and using specialized equipment or a pig to remove the wax deposit from the pipe wall surface.

References

- ↑ Shuqiang Gao; Waylon House; Walter G. Chapman (2006). "Detecting Gas Hydrate Behavior in Crude Oil Using NMR". J. Phys. Chem. B. 110 (13): 6549–6552. doi:10.1021/jp055039a. PMID 16570953.

- ↑ "Coping with flow assurance - Offshore". www.offshore-mag.com. Archived from the original on 13 September 2012. Retrieved 6 June 2022.

- ↑ "Flow assurance: A sensitive issue for any oil development project". 10 August 2016.

- ↑ http://hydrates.white.prohosting.com/%5B%5D

- ↑ Shuqiang Gao (2008). "Investigation of Interactions between Gas Hydrates and Several Other Flow Assurance Elements". Energy Fuels. 22 (5): 3150–3153. doi:10.1021/ef800189k.

- ↑ Yadua, Asekhame U.; Lawal, Kazeem A.; Okoh, Oluchukwu M.; Ovuru, Mathilda I.; Eyitayo, Stella I.; Matemilola, Saka; Obi, Chinyere C. (2020-12-01). "Stability and stable production limit of an oil production well". Journal of Petroleum Exploration and Production Technology. 10 (8): 3673–3687. doi: 10.1007/s13202-020-00985-3 . ISSN 2190-0566.