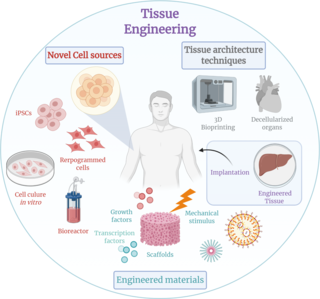

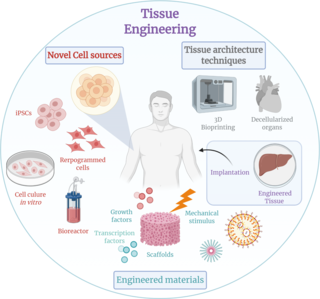

Tissue engineering is a biomedical engineering discipline that uses a combination of cells, engineering, materials methods, and suitable biochemical and physicochemical factors to restore, maintain, improve, or replace different types of biological tissues. Tissue engineering often involves the use of cells placed on tissue scaffolds in the formation of new viable tissue for a medical purpose, but is not limited to applications involving cells and tissue scaffolds. While it was once categorized as a sub-field of biomaterials, having grown in scope and importance, it can is considered as a field of its own.

Cultured meat, also known as cultivated meat among other names, is a form of cellular agriculture where meat is produced by culturing animal cells in vitro. Cultured meat is produced using tissue engineering techniques pioneered in regenerative medicine. Jason Matheny popularized the concept in the early 2000s after he co-authored a paper on cultured meat production and created New Harvest, the world's first non-profit organization dedicated to in-vitro meat research. Cultured meat has the potential to address the environmental impact of meat production, animal welfare, food security and human health, in addition to its potential mitigation of climate change.

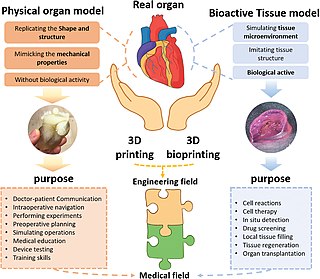

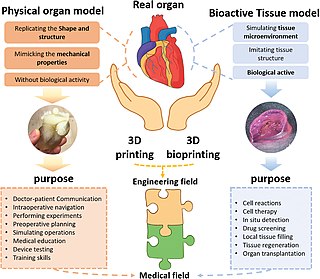

Organ printing utilizes techniques similar to conventional 3D printing where a computer model is fed into a printer that lays down successive layers of plastics or wax until a 3D object is produced. In the case of organ printing, the material being used by the printer is a biocompatible plastic. The biocompatible plastic forms a scaffold that acts as the skeleton for the organ that is being printed. As the plastic is being laid down, it is also seeded with human cells from the patient's organ that is being printed for. After printing, the organ is transferred to an incubation chamber to give the cells time to grow. After a sufficient amount of time, the organ is implanted into the patient.

Biological engineering or bioengineering is the application of principles of biology and the tools of engineering to create usable, tangible, economically viable products. Biological engineering employs knowledge and expertise from a number of pure and applied sciences, such as mass and heat transfer, kinetics, biocatalysts, biomechanics, bioinformatics, separation and purification processes, bioreactor design, surface science, fluid mechanics, thermodynamics, and polymer science. It is used in the design of medical devices, diagnostic equipment, biocompatible materials, renewable energy, ecological engineering, agricultural engineering, process engineering and catalysis, and other areas that improve the living standards of societies.

Ali Khademhosseini is the CEO of the Terasaki Institute, non-profit research organization in Los Angeles, and Omeat Inc., a cultivated-meat startup. Before taking his current CEO roles, he spent one year at Amazon Inc. Prior to that he was the Levi Knight chair and professor at the University of California-Los Angeles where he held a multi-departmental professorship in Bioengineering, Radiology, Chemical, and Biomolecular Engineering as well as the Director of Center for Minimally Invasive Therapeutics (C-MIT). From 2005 to 2017, he was a professor at Harvard Medical School, and the Wyss Institute for Biologically Inspired Engineering.

The Methuselah Foundation is an American-based global non-profit organization based in Springfield, Virginia, with a declared mission to "make 90 the new 50 by 2030" by supporting tissue engineering and regenerative medicine therapies. The organization was originally incorporated by David Gobel in 2001 as the Performance Prize Society, a name inspired by the British governments Longitude Act, which offered monetary rewards for anyone who could devise a portable, practical solution for determining a ship's longitude.

Three dimensional (3D) bioprinting is the utilization of 3D printing–like techniques to combine cells, growth factors, bio-inks, and biomaterials to fabricate functional structures that were traditionally used for tissue engineering applications but in recent times have seen increased interest in other applications such as biosensing, and environmental remediation. Generally, 3D bioprinting utilizes a layer-by-layer method to deposit materials known as bio-inks to create tissue-like structures that are later used in various medical and tissue engineering fields. 3D bioprinting covers a broad range of bioprinting techniques and biomaterials. Currently, bioprinting can be used to print tissue and organ models to help research drugs and potential treatments. Nonetheless, translation of bioprinted living cellular constructs into clinical application is met with several issues due to the complexity and cell number necessary to create functional organs. However, innovations span from bioprinting of extracellular matrix to mixing cells with hydrogels deposited layer by layer to produce the desired tissue. In addition, 3D bioprinting has begun to incorporate the printing of scaffolds which can be used to regenerate joints and ligaments. Apart from these, 3D bioprinting has recently been used in environmental remediation applications, including the fabrication of functional biofilms that host functional microorganisms that can facilitate pollutant removal.

Organovo is an early-stage medical laboratory and research company which designs and develops functional, three dimensional human tissue for medical research and therapeutic applications. Organovo was established in 2007 and is headquartered in San Diego, California. The company uses its internally developed NovoGen MMX Bioprinter for 3D bioprinting.

Ethics of bioprinting is a sub-field of ethics concerning bioprinting. Some of the ethical issues surrounding bioprinting include equal access to treatment, clinical safety complications, and the enhancement of human body.

Cellular agriculture focuses on the production of agricultural products from cell cultures using a combination of biotechnology, tissue engineering, molecular biology, and synthetic biology to create and design new methods of producing proteins, fats, and tissues that would otherwise come from traditional agriculture. Most of the industry is focused on animal products such as meat, milk, and eggs, produced in cell culture rather than raising and slaughtering farmed livestock which is associated with substantial global problems of detrimental environmental impacts, animal welfare, food security and human health. Cellular agriculture is a field of the biobased economy. The most well known cellular agriculture concept is cultured meat.

Bio-inks are materials used to produce engineered/artificial live tissue using 3D printing. These inks are mostly composed of the cells that are being used, but are often used in tandem with additional materials that envelope the cells. The combination of cells and usually biopolymer gels are defined as a bio-ink. They must meet certain characteristics, including such as rheological, mechanical, biofunctional and biocompatibility properties, among others. Using bio-inks provides a high reproducibility and precise control over the fabricated constructs in an automated manner. These inks are considered as one of the most advanced tools for tissue engineering and regenerative medicine (TERM).

Antonios Georgios Mikos is a Greek-American biomedical engineer who is the Louis Calder Professor of Bioengineering and Chemical and Biomolecular Engineering at Rice University. He specialises in biomaterials, drug delivery, and tissue engineering.

Akhilesh K. Gaharwar is an Indian academic and a professor in the Department of Biomedical Engineering at Texas A&M University. The goal of his lab is to understand the cell-nanomaterials interactions and to develop nanoengineered strategies for modulating stem cell behavior for repair and regeneration of damaged tissue.

Bico Group is a bioconvergence startup that designs and supplies technologies and services to enhance biology research. It focuses on commercializing technologies for life science research as well as bioprinting, and its products often combine capabilities in artificial intelligence, robotics, multiomics, and diagnostics.

Aleph Farms is a cellular agriculture company active in the food technology space. It was co-founded in 2017 by the Israeli food-tech incubator "The Kitchen Hub" of Strauss Group Ltd., and Prof. Shulamit Levenberg of the Faculty of Biomedical Engineering at Technion – Israel Institute of Technology and is headquartered in Rehovot, Israel.

Novameat is a food tech startup that works with plant-based foods, including plant-based meat substitutes. According to El País, the company was responsible in 2018 for creating a meat substitute through 3D printing, whereby a plant-based paste was used with syringes placed in a 3D printer using AutoCAD software.

3D food printing is the process of manufacturing food products using a variety of additive manufacturing techniques. Most commonly, food grade syringes hold the printing material, which is then deposited through a food grade nozzle layer by layer. The most advanced 3D food printers have pre-loaded recipes on board and also allow the user to remotely design their food on their computers, phones or some IoT device. The food can be customized in shape, color, texture, flavor or nutrition, which makes it very useful in various fields such as space exploration and healthcare.

Microgravity bioprinting is the utilization of 3D bioprinting techniques under microgravity conditions to fabricate highly complex, functional tissue and organ structures. The zero gravity environment circumvents some of the current limitations of bioprinting on Earth including magnetic field disruption and biostructure retention during the printing process. Microgravity bioprinting is one of the initial steps to advancing in space exploration and colonization while furthering the possibilities of regenerative medicine.

Bioprinting drug delivery is a method of using the three-dimensional printing of biomaterials through an additive manufacturing technique to develop drug delivery vehicles that are biocompatible tissue-specific hydrogels or implantable devices. 3D bioprinting uses printed cells and biological molecules to manufacture tissues, organs, or biological materials in a scaffold-free manner that mimics living human tissue to provide localized and tissue-specific drug delivery, allowing for targeted disease treatments with scalable and complex geometry.

Thanh Cong Dinh, also known as Paul Dinh or THANH, is a Vietnamese American inventor and music producer who was born in Hanoi, Vietnam. Thanh is best known internationally for his innovative cornea 3D printing research and his song "Soju on Sunday".