Related Research Articles

Gypsum is a soft sulfate mineral composed of calcium sulfate dihydrate, with the chemical formula CaSO4·2H2O. It is widely mined and is used as a fertilizer and as the main constituent in many forms of plaster, drywall and blackboard or sidewalk chalk. Gypsum also crystallizes as translucent crystals of selenite. It forms as an evaporite mineral and as a hydration product of anhydrite. The Mohs scale of mineral hardness defines gypsum as hardness value 2 based on scratch hardness comparison.

Drywall is a panel made of calcium sulfate dihydrate (gypsum), with or without additives, typically extruded between thick sheets of facer and backer paper, used in the construction of interior walls and ceilings. The plaster is mixed with fiber ; plasticizer, foaming agent; and additives that can reduce mildew, flammability, and water absorption.

USG Corporation, also known as United States Gypsum Corporation, is an American company which manufactures construction materials, most notably drywall and joint compound. The company is the largest distributor of wallboard in the United States and the largest manufacturer of gypsum products in North America. It is also a major consumer of synthetic gypsum, a byproduct of flue-gas desulfurization. Its corporate offices are located at 550 West Adams Street in Chicago, Illinois.

BPB Ltd was a British building materials business. It once was a constituent of the FTSE 100 Index. In 2005, the company was purchased by Saint-Gobain of France. The company's subsidiary British Gypsum, which was the UK operating arm of the company, operates as a subsidiary of Saint-Gobain, with five manufacturing sites in Britain as of 2012.

Glass recycling is the processing of waste glass into usable products. Glass that is crushed or imploded and ready to be remelted is called cullet. There are two types of cullet: internal and external. Internal cullet is composed of defective products detected and rejected by a quality control process during the industrial process of glass manufacturing, transition phases of product changes and production offcuts. External cullet is waste glass that has been collected or reprocessed with the purpose of recycling. External cullet is classified as waste. The word "cullet", when used in the context of end-of-waste, will always refer to external cullet.

Biodegradable waste includes any organic matter in waste which can be broken down into carbon dioxide, water, methane, compost, humus, and simple organic molecules by micro-organisms and other living things by composting, aerobic digestion, anaerobic digestion or similar processes. It mainly includes kitchen waste, ash, soil, dung and other plant matter. In waste management, it also includes some inorganic materials which can be decomposed by bacteria. Such materials include gypsum and its products such as plasterboard and other simple sulfates which can be decomposed by sulfate reducing bacteria to yield hydrogen sulfide in anaerobic land-fill conditions.

Landfill mining and reclamation (LFMR) is a process which excavates and processes solid wastes which have previously been landfilled. The process aims to reduce the amount of landfill mass encapsulated within the closed landfill and/or temporarily remove hazardous material to allow protective measures to be taken before the landfill mass is replaced. In the process, mining recovers valuable recyclable materials, a combustible fraction, soil, and landfill space. The aeration of the landfill soil is a secondary benefit with regard to the landfill's future use. The combustible fraction is useful for power generation. The overall appearance of the landfill mining procedure is a sequence of processing machines laid out in a functional conveyor system. The operating principle is to excavate, sieve and sort the landfill material.

Construction waste or debris is any kind of debris from the construction process. Different government agencies have clear definitions. For example, the United States Environmental Protection Agency EPA defines construction and demolition materials as “debris generated during the construction, renovation and demolition of buildings, roads, and bridges.” Additionally, the EPA has categorized Construction and Demolition (C&D) waste into three categories: non-dangerous, hazardous, and semi-hazardous.

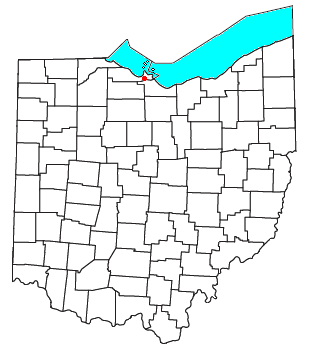

Gypsum is an unincorporated community in eastern Portage Township, Ottawa County, Ohio, United States. It has a post office with the ZIP code 43433.

Kalundborg Eco-Industrial Park is an industrial symbiosis network located in Kalundborg, Denmark, in which companies in the region collaborate to use each other's by-products and otherwise share resources.

Waste are unwanted or unusable materials. Waste is any substance discarded after primary use, or is worthless, defective and of no use. A by-product, by contrast is a joint product of relatively minor economic value. A waste product may become a by-product, joint product or resource through an invention that raises a waste product's value above zero.

Magnesium oxide, more commonly called magnesia, is a mineral that when used as part of a cement mixture and cast into thin cement panels under proper curing procedures and practices can be used in residential and commercial building construction. Some versions are suitable for general building uses and for applications that require fire resistance, mold and mildew control, as well as sound control applications. Magnesia board has strength and resistance due to very strong bonds between magnesium and oxygen atoms that form magnesium oxide crystals.

Demolition waste is waste debris from destruction of buildings, roads, bridges, or other structures. Debris varies in composition, but the major components, by weight, in the US include concrete, wood products, asphalt shingles, brick and clay tile, steel, and drywall. There is the potential to recycle many elements of demolition waste.

Knauf Gips KG is a multinational, family-owned company based in Iphofen, Germany, well known for drywall gypsum boards, founded in 1932. The company is a producer of building materials and construction systems comprising construction materials for drywall construction, plasterboard, cement boards, mineral fibre acoustic boards, dry mortars with gypsum for internal plaster and cement-based external plaster and insulating materials; glass wool, stone wool and other insulation materials under the company Knauf Insulation.

Products made from a variety of materials can be recycled using a number of processes.

Resource recovery is using wastes as an input material to create valuable products as new outputs. The aim is to reduce the amount of waste generated, thereby reducing the need for landfill space, and optimising the values created from waste. Resource recovery delays the need to use raw materials in the manufacturing process. Materials found in municipal solid waste, construction and demolition waste, commercial waste and industrial wastes can be used to recover resources for the manufacturing of new materials and products. Plastic, paper, aluminium, glass and metal are examples of where value can be found in waste.

Gypsum block is a massive lightweight building material composed of solid gypsum, for building and erecting lightweight, fire-resistant, non-load bearing interior walls, partition walls, cavity walls, skin walls, and pillar casing indoors. Gypsum blocks are composed of gypsum, plaster, water and in some cases additives like vegetable or wood fiber for greater strength. Partition walls, made from gypsum blocks, require no sub-structure for erection and gypsum adhesive is used as bonding agent, not standard mortar. Because of this fundamental difference, gypsum blocks shouldn't be confused with the thinner plasterboard used for paneling stud walls.

Grenzebach BSH (GmbH) was established following the take-over of Babcock-BSH GmbH by Grenzebach Maschinenbau GmbH. Grenzebach BSH GmbH has its registered office in Bad Hersfeld, Germany, and has been a member of the Grenzebach group since October 2002. The company employs some 350 people and at the Bad Hersfeld location continues its predecessor's activities as a supplier of equipment and services for the wood processing and building materials industries as well as the process technology sector. Its offices and workshops were first located in buildings that in part dated back to the old Schilde AG. Beginning in the summer of 2007, engineering and administration were the first departments to move into a new office building located at Gewerbepark Hohe Luft, a business park at the periphery of Bad Hersfeld. Construction of a new factory building right next to the offices began in 2008 and was completed in 2009. Manufacturing and the remaining departments such as R&D and logistics then also moved in from mid-2009. By the end of 2009 all buildings on the former Schilde premises in the town centre were vacated and handed back their owner, the town of Bad Hersfeld.

Gypsum Recycling International A/S (GRI) is a recycling company based in Nærum, Rudersdal Municipality, Denmark. GRI offers a system for the recycling of gypsum and plasterboard/drywall waste.

Clay panel or clay board is a panel made of clay with some additives. The clay is mixed with sand, water, and fiber, typically wood fiber, and sometimes other additives like starch. Most often this means employing the use of high-cellulose waste fibres. To improve the breaking resistance clay boards are often embedded in a hessian skin on the backside or similar embeddings.

References

- 1 2 3 European Commission. http://ec.europa.eu/environment/life/project/Projects/index.cfm?fuseaction=search.dspPage&n_proj_id=4191 Retrieved 3 October 2013

- 1 2 WRAP, Technical Report. Life Cycle Assessment of Plasterboard. 2008. http://www2.wrap.org.uk/downloads/Life_Cycle_Assessment_of_Plasterboard.2a99ccc6.5313.pdf%5B%5D Retrieved 26 September 2013.

- ↑ Recycling Council of British Columbia. Why can't I put my leftover gyproc/drywall in the garbage? Retrieved from <http://rcbc.bc.ca/education/faqs/hazard9 Archived 2013-10-21 at the Wayback Machine >

- ↑ Environmental Protection Agency. State of Ohio. Fact Sheet: Methane and Hydrogen Sulfide Gases at C&DD Landfills. Retrieved from <http://epa.ohio.gov/portals/34/document/guidance/gd_669.pdf>

- ↑ Khalil, M. A. K. (1999). "Non-Co2Greenhousegases Intheatmosphere". Annual Review of Energy and the Environment . 24: 645–661. doi: 10.1146/annurev.energy.24.1.645 .

- ↑ EUROGYPSUM, Environmental and Raw Material Committee. Factsheet on: What is gypsum? http://www.eurogypsum.org/_uploads/dbsattachedfiles/whatisgypsum.pdf Archived 2013-12-02 at the Wayback Machine [ dead link ]

- ↑ Saint-Gobain Gyproc Finland. Letter written by the Plant Director. June 2013

- ↑ WRAP. Plasterboard Case Study. International practice in plasterboard recycling: Denmark. Gypsum Recycling International A/S.

- ↑ Gypsum to Gypsum: From Production to Recycling, a Circular Economy for the European Gypsum Industry with the Demolition and Recycling Industry. LIFE11 ENV/BE/001039. <http://gypsumtogypsum.org/ Archived 2013-12-03 at the Wayback Machine > Retrieved 26 September 2013.

- ↑ Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on waste and repealing certain Directives

- ↑ "Home". usagypsum.com.