Labour laws, labour code or employment laws are those that mediate the relationship between workers, employing entities, trade unions, and the government. Collective labour law relates to the tripartite relationship between employee, employer, and union.

Child labour is the exploitation of children through any form of work that interferes with their ability to attend regular school, or is mentally, physically, socially and morally harmful. Such exploitation is prohibited by legislation worldwide, although these laws do not consider all work by children as child labour; exceptions include work by child artists, family duties, supervised training, and some forms of work undertaken by Amish children, as well as by Indigenous children in the Americas.

Quarry Bank Mill in Styal, Cheshire, England, is one of the best preserved textile factories of the Industrial Revolution. Built in 1784, the cotton mill is recorded in the National Heritage List for England as a designated Grade II* listed building. Quarry Bank Mill was established by Samuel Greg, and was notable for innovations both in machinery and also in its approach to labour relations, the latter largely as a result of the work of Greg's wife, Hannah Lightbody. The family took a somewhat paternalistic attitude toward the workers, providing medical care for all and limited education to the children, but all laboured roughly 72 hours per week until 1847 when a new law shortened the hours.

A cotton mill is a building that houses spinning or weaving machinery for the production of yarn or cloth from cotton, an important product during the Industrial Revolution in the development of the factory system.

Textile manufacture during the British Industrial Revolution was centred in south Lancashire and the towns on both sides of the Pennines in the United Kingdom. The main drivers of the Industrial Revolution were textile manufacturing, iron founding, steam power, oil drilling, the discovery of electricity and its many industrial applications, the telegraph and many others. Railroads, steamboats, the telegraph and other innovations massively increased worker productivity and raised standards of living by greatly reducing time spent during travel, transportation and communications.

The factory system is a method of manufacturing using machinery and division of labor. Because of the high capital cost of machinery and factory buildings, factories are typically privately owned by wealthy individuals or corporations who employ the operative labor. Use of machinery with the division of labor reduced the required skill-level of workers and also increased the output per worker.

The Factory Acts were a series of acts passed by the Parliament of the United Kingdom beginning in 1802 to regulate and improve the conditions of industrial employment.

Sir Robert Peel, 1st Baronet, was a British politician and industrialist and one of early textile manufacturers of the Industrial Revolution. He was one of the ten known British millionaires in 1799.

John Fielden was a British industrialist and Radical Member of Parliament for Oldham (1832–1847).

The Sadler Report, also known as the Report of the Select Committee on Factory Children's Labour or "the report of Mr Sadler’s Committee," was a report written in 1832 by Michael Sadler, the chairman of a UK Parliamentary committee considering a bill that limited the hours of work of children in textile mills and factories. In committee hearings carried out between the passage of the 1832 Reform Act and Parliament’s subsequent dissolution, Sadler had elicited testimony from factory workers, concerned medical men, and other bystanders. The report highlighted the poor working conditions and excessive working hours for children working in the factories. Time prevented balancing or contrary evidence from being called before Parliament was dissolved.

Murrays' Mills is a complex of former cotton mills on land between Jersey Street and the Rochdale Canal in the district of Ancoats, Manchester, England. The mills were built for brothers Adam and George Murray.

Life in Great Britain during the Industrial Revolution shifted from an agrarian based society to an urban, industrialised society. New social and technological ideas were developed, such as the factory system and the steam engine. Work became more regimented, disciplined, and moved outside the home with large segments of the rural population migrating to the cities.

The History of labour law in the United Kingdom concerns the development of UK labour law, from its roots in Roman and medieval times in the British Isles up to the present. Before the Industrial Revolution and the introduction of mechanised manufacture, regulation of workplace relations was based on status, rather than contract or mediation through a system of trade unions. Serfdom was the prevailing status of the mass of people, except where artisans in towns could gain a measure of self-regulation through guilds. In 1740 save for the fly-shuttle the loom was as it had been since weaving had begun. The law of the land was, under the Act of Apprentices 1563, that wages in each district should be assessed by Justices of the Peace. From the middle of the 19th century, through Acts such as the Master and Servant Act 1867 and the Employers and Workmen Act 1875, there became growing recognition that greater protection was needed to promote the health and safety of workers, as well as preventing unfair practices in wage contracts.

The history of labour law concerns the development of labour law as a way of regulating and improving the life of people at work. In the civilisations of antiquity, the use of slave labour was widespread. Some of the maladies associated with unregulated labour were identified by Pliny as "diseases of slaves."

The Factories Act 1847, also known as the Ten Hours Act was a United Kingdom Act of Parliament which restricted the working hours of women and young persons (13–18) in textile mills to 10 hours per day. The practicalities of running a textile mill were such that the Act should have effectively set the same limit on the working hours of adult male mill-workers.

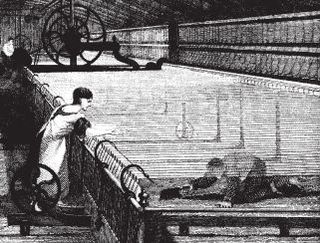

Scavengers were employed in 18th and 19th century in cotton mills, predominantly in the UK and the United States, to clean and recoup the area underneath a spinning mule. The cotton wastage that gathered on the floor was seen as too valuable for the owners to leave and one of the simplest solutions was to employ young children to work under the machinery. Many children suffered serious injuries while under the mules, with fingers, hands, and sometimes heads crushed by the heavy moving parts. Legislation introduced in 1819 tried to reduce working hours and improve conditions but there were still deaths recorded well beyond the middle of the 19th century.

A doffer is someone who removes "doffs" holding spun fiber such as cotton or wool from a spinning frame and replaces them with empty ones. Historically, spinners, doffers, and sweepers each had separate tasks that were required in the manufacture of spun textiles. From the early days of the industrial revolution, this work, which requires speed and dexterity rather than strength, was often done by children. After World War I, the practice of employing children declined, ending in the United States in 1933. In modern textile mills, doffing machines have now replaced humans.

Steaming or artificial humidity was the process of injecting steam from boilers into cotton weaving sheds in Lancashire, England, in the late 19th and early 20th centuries. The intention was to prevent breakages in short-staple Indian Surat cotton which was introduced in 1862 during a blockade of American cotton at the time of the American Civil War. There was considerable concern about the health implications of steaming. Believed to cause ill health, this practice became the subject of much campaigning and investigation from the 1880s to the 1920s. A number of Acts of Parliament imposed modifications.

The Cotton Mills and Factories Act 1819 was an Act of the Parliament of the United Kingdom, which was its first attempt to regulate the hours and conditions of work of children in the cotton industry. It was introduced by Sir Robert Peel, who had first introduced a bill on the matter in 1815. The 1815 bill had been instigated by Robert Owen, but the Act as passed was much weaker than the 1815 bill; the Act forbade the employment of children under 9; children aged 9–16 years were limited to 12 hours' work per day and could not work at night. There was no effective means of its enforcement, but it established the precedent for Parliamentary intervention on conditions of employment which was followed by subsequent Factory Acts.

A factory inspector is someone who checks that factories comply with regulations affecting them.