Distributed generation, also distributed energy, on-site generation (OSG), or district/decentralized energy, is electrical generation and storage performed by a variety of small, grid-connected or distribution system-connected devices referred to as distributed energy resources (DER).

Geosynthetics are synthetic products used to stabilize terrain. They are generally polymeric products used to solve civil engineering problems. This includes eight main product categories: geotextiles, geogrids, geonets, geomembranes, geosynthetic clay liners, geofoam, geocells and geocomposites. The polymeric nature of the products makes them suitable for use in the ground where high levels of durability are required. They can also be used in exposed applications. Geosynthetics are available in a wide range of forms and materials. These products have a wide range of applications and are currently used in many civil, geotechnical, transportation, geoenvironmental, hydraulic, and private development applications including roads, airfields, railroads, embankments, retaining structures, reservoirs, canals, dams, erosion control, sediment control, landfill liners, landfill covers, mining, aquaculture and agriculture.

James F. Jacoby is an American businessman based out of Atlanta, Georgia. Jacoby is the founder, chairman and CEO of The Jacoby Group, Inc., a synergistic group of operating companies headquartered in Atlanta, Georgia. The nationally recognized Jacoby Development, Inc., a land development company that specializes in environmentally sensitive multi-use properties and reclamation of impaired sites brownfields is a member of the group.

A geomembrane is very low permeability synthetic membrane liner or barrier used with any geotechnical engineering related material so as to control fluid migration in a human-made project, structure, or system. Geomembranes are made from relatively thin continuous polymeric sheets, but they can also be made from the impregnation of geotextiles with asphalt, elastomer or polymer sprays, or as multilayered bitumen geocomposites. Continuous polymer sheet geomembranes are, by far, the most common.

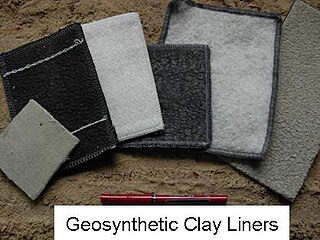

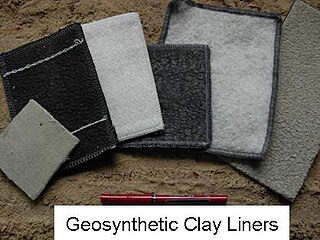

Geosynthetic clay liners (GCLs) are factory manufactured hydraulic barriers consisting of a layer of bentonite or other very low-permeability material supported by geotextiles and/or geomembranes, mechanically held together by needling, stitching, or chemical adhesives. Due to environmental laws, any seepage from landfills must be collected and properly disposed of, otherwise contamination of the surrounding ground water could cause major environmental and/or ecological problems. The lower the hydraulic conductivity the more effective the GCL will be at retaining seepage inside of the landfill. Bentonite composed predominantly (>70%) of montmorillonite or other expansive clays, are preferred and most commonly used in GCLs. A general GCL construction would consist of two layers of geosynthetics stitched together enclosing a layer of natural or processed sodium bentonite. Typically, woven and/or non-woven textile geosynthetics are used, however polyethylene or geomembrane layers or geogrid geotextiles materials have also been incorporated into the design or in place of a textile layer to increase strength. GCLs are produced by several large companies in North America, Europe, and Asia. The United States Environmental Protection Agency currently regulates landfill construction and design in the US through several legislations.

A landfill liner, or composite liner, is intended to be a low permeable barrier, which is laid down under engineered landfill sites. Until it deteriorates, the liner retards migration of leachate, and its toxic constituents, into underlying aquifers or nearby rivers, causing potentially irreversible contamination of the local waterway and its sediments.

There are several solar power plants in the Mojave Desert which supply power to the electricity grid. Insolation in the Mojave Desert is among the best available in the United States, and some significant population centers are located in the area. These plants can generally be built in a few years because solar plants are built almost entirely with modular, readily available materials. Solar Energy Generating Systems (SEGS) is the name given to nine solar power plants in the Mojave Desert which were built in the 1980s, the first commercial solar plant. These plants have a combined capacity of 354 megawatts (MW) which made them the largest solar power installation in the world, until Ivanpah Solar Power Facility was finished in 2014.

A photovoltaic system, also called a PV system or solar power system, is an electric power system designed to supply usable solar power by means of photovoltaics. It consists of an arrangement of several components, including solar panels to absorb and convert sunlight into electricity, a solar inverter to convert the output from direct to alternating current, as well as mounting, cabling, and other electrical accessories to set up a working system. It may also use a solar tracking system to improve the system's overall performance and include an integrated battery.

Topaz Solar Farm is a 550 megawatt (MWAC) photovoltaic power station in San Luis Obispo County, California, United States. Construction on the project began in November 2011 and ended in November 2014. It is one of the world's largest solar farms. The $2.5 billion project includes 9 million CdTe photovoltaic modules based on thin-film technology, manufactured by U.S. company First Solar. The company also built, operates and maintains the project for MidAmerican Renewables, a Berkshire Hathaway company. Pacific Gas and Electric will buy the electricity under a 25-year power purchase agreement. According to First Solar, it created about 400 construction jobs.

Cadmium telluride (CdTe) photovoltaics is a photovoltaic (PV) technology based on the use of cadmium telluride in a thin semiconductor layer designed to absorb and convert sunlight into electricity. Cadmium telluride PV is the only thin film technology with lower costs than conventional solar cells made of crystalline silicon in multi-kilowatt systems.

The use of solar energy began in Israel in the 1950s with the development by Levi Yissar of a solar water heater to address the energy shortages that plagued the new country. By 1967 around 5% of water of households were solar heated and 50,000 solar heaters had been sold. With the 1970s oil crisis, Harry Zvi Tabor developed the prototype of the solar water heater now used in over 90% of Israeli homes. There are over 1.3 million solar water heaters installed as a result of mandatory solar water heating regulations.

New Jersey has over 4,700 MW of installed solar power capacity as of January 2024, which provides more than 7% of the state's electricity consumption. The's state's growth of solar power is aided by a renewable portfolio standard that requires that 22.5% of New Jersey's electricity come from renewable resources by 2021 and 50% by 2030, by incentives provided for generation of solar power, and by one of the most favorable net metering standards in the country, allowing customers of any size array to use net metering, although generation may not exceed annual demand. As of 2018, New Jersey has the sixth-largest installed solar capacity of all U.S. states and the largest installed solar capacity of the Northeastern States.

A photovoltaic power station, also known as a solar park, solar farm, or solar power plant, is a large-scale grid-connected photovoltaic power system designed for the supply of merchant power. They are different from most building-mounted and other decentralized solar power because they supply power at the utility level, rather than to a local user or users. Utility-scale solar is sometimes used to describe this type of project.

Solar power in France including overseas territories reached an installed capacity figure of 11.2 GW in 2020, and rose further to 17.1 GW at the end of 2022. Government plans announced in 2022 foresee solar PV capacity in France rising to 100 GW by 2050.

Solar power in Georgia on rooftops can provide 31% of all electricity used in Georgia.

Solar power in Illinois has been increasing, as the cost of photovoltaics has decreased. As of the end of 2020, Illinois had 465 megawatts (MW) of installed photovoltaic and concentrated solar power capacity combined employing over 5,200 jobs. Illinois adopted a net metering rule which allows customers generating up to 40 kW to use net metering, with the kilowatt hour surplus rolled over each month, and lost at the end of either April or October, as selected by the customer. In 2011, the limit was raised to 2 MW, but is not net metering, as the term is commonly known, as it uses two meters for systems larger than 40 kW.

The United States state of Arkansas is a significant producer of natural gas and a minor producer of petroleum.

Ronald Kerry Rowe, OC, BSc, BE, PhD, D.Eng, DSc (hc), FRS, FREng, NAE, FRSC, FCAE, Dist.M.ASCE, FEIC, FIE(Aust), FCSCE, PEng., CPEng. is a Canadian civil engineer of Australian birth, one of the pioneers of geosynthetics.

Jean-Pierre Giroud is a French geotechnical engineer and a pioneer of geosynthetics since 1970. In 1977, he coined the words "geotextile" and "geomembrane", thus initiating the "geo-terminology". He is also a past president of the International Geosynthetics Society, member of the US National Academies, and Chevalier de la Légion d'Honneur.

The Eubank Landfill Solar Array is a photovoltaic power station in Albuquerque, New Mexico that consists of 1.0 MWAC of concentrator photovoltaics (CPV) and 1.0 MWAC of flat-panel silicon photovoltaics (PV). It is the only utility-scale CPV system utilizing Suncore third-generation technology that is operational and grid-connected in the US. A portion of the output is being sold to PNM under a Power Purchase Agreement.