Iron ores are rocks and minerals from which metallic iron can be economically extracted. The ores are usually rich in iron oxides and vary in color from dark grey, bright yellow, or deep purple to rusty red. The iron is usually found in the form of magnetite (Fe

3O

4, 72.4% Fe), hematite (Fe

2O

3, 69.9% Fe), goethite (FeO(OH), 62.9% Fe), limonite (FeO(OH)·n(H2O), 55% Fe) or siderite (FeCO3, 48.2% Fe).

The Mesabi Iron Range is a mining district and mountain range in northeastern Minnesota following an elongate trend containing large deposits of iron ore. It is the largest of four major iron ranges in the region collectively known as the Iron Range of Minnesota. First described in 1866, it is the chief iron ore mining district in the United States. The district is located largely in Itasca and Saint Louis counties. It has been extensively worked since 1892, and has seen a transition from high-grade direct shipping ores through gravity concentrates to the current industry exclusively producing iron ore (taconite) pellets. Production has been dominantly controlled by vertically integrated steelmakers since 1901, and therefore is dictated largely by US ironmaking capacity and demand.

Taconite is a variety of banded iron formation, an iron-bearing sedimentary rock, in which the iron minerals are interlayered with quartz, chert, or carbonate. The name "taconyte" was coined by Horace Vaughn Winchell (1865–1923) – son of Newton Horace Winchell, the Minnesota State Geologist – during their pioneering investigations of the Precambrian Biwabik Iron Formation of northeastern Minnesota. He believed the sedimentary rock sequence hosting the iron-formation was correlative with the Taconic orogeny of New England, and referred to the unfamiliar and as-yet-unnamed iron-bearing rock as the 'taconic rock' or taconyte.

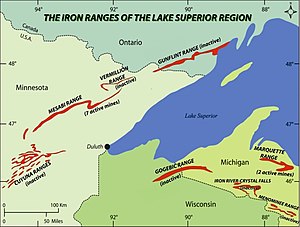

The Iron Range is collectively or individually a number of elongated iron-ore mining districts around Lake Superior in the United States and Canada. Much of the ore-bearing region lies alongside the range of granite hills formed by the Giants Range batholith. These cherty iron ore deposits are Precambrian in the Vermilion Range and middle Precambrian in the Mesabi and Cuyuna ranges, all in Minnesota. The Gogebic Range in Wisconsin and the Marquette Iron Range and Menominee Range in Michigan have similar characteristics and are of similar age. Natural ores and concentrates were produced from 1848 until the mid-1950s, when taconites and jaspers were concentrated and pelletized, and started to become the major source of iron production.

The Vermilion Range exists between Tower, Minnesota and Ely, Minnesota, and contains significant deposits of iron ore. Together with the Mesabi, Gunflint, and Cuyuna ranges, these four constitute the Iron Ranges of northern Minnesota. While the Mesabi Range had iron ore close enough to the surface to enable pit mining, mines had to be dug deep underground to reach the ore of the Vermilion and Cuyuna ranges. The Soudan mine was nearly 1/2 mile underground and required blasting of Precambrian sedimentary bedrock.

The Cuyuna Range is an inactive iron range to the southwest of the Mesabi Range, largely within Crow Wing County, Minnesota. It lies along a 68-mile-long (109 km) line between Brainerd, Minnesota, and Aitkin, Minnesota. The width ranges from 1 to 10 miles.

The Hull–Rust–Mahoning Open Pit Iron Mine in Hibbing, Minnesota, United States, is the largest operating open-pit iron mine in Minnesota. The pit stretches more than three miles (5 km) long, two miles (3 km) wide, and 535 feet (163 m) deep. It was established in 1895 and was one of the world's first mechanized open-pit mines.

Cleveland-Cliffs Inc. is an American steel manufacturer based in Cleveland, Ohio. They specialize in the mining, beneficiation, and pelletizing of iron ore, as well as steelmaking, including stamping and tooling. The company was the world's 25th-largest steel producer and the third-largest in the United States in 2022. It is the largest flat-rolled steel producer in North America.

The Seven Iron Men, also known as Merritt Brothers, were iron-ore pioneers in the Mesabi Range in northeastern Minnesota and the creation of the city that is now known as Mountain Iron. In the late 1800s, the Merritt family founded the largest iron mine in the world and initiated the consolidation of the American railway system into what would ultimately become the United States Steel Corporation. Their story was told, in part, by the book Seven Iron Men by Paul de Kruif. The book was first published in 1929.

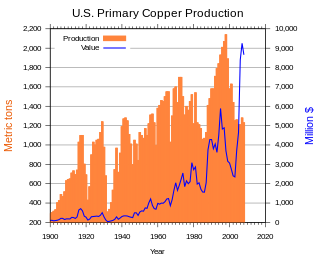

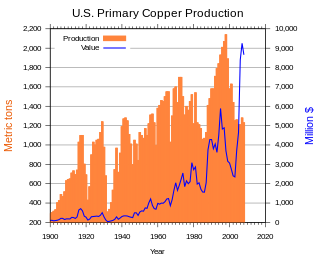

In the United States, copper mining has been a major industry since the rise of the northern Michigan copper district in the 1840s. In 2017, the US produced 1.27 million metric tonnes of copper, worth $8 billion, making it the world's fourth largest copper producer, after Chile, China, and Peru. Copper was produced from 23 mines in the US. Top copper producing states in 2014 were Arizona, Utah, New Mexico, Nevada, and Montana. Minor production also came from Idaho, and Missouri. As of 2014, the US had 45 million tonnes of known remaining reserves of copper, the fifth largest known copper reserves in the world, after Chile, Australia, Peru, and Mexico.

The Gogebic Range is an elongated area of iron ore deposits located within a range of hills in northern Michigan and Wisconsin just south of Lake Superior. It extends from Lake Namakagon in Wisconsin eastward to Lake Gogebic in Michigan, or almost 80 miles. Though long, it is only about a half mile wide and forms a crescent concave to the southeast. The Gogebic Range includes the communities of Ironwood in Michigan, plus Mellen and Hurley in Wisconsin.

An ore dock is a large structure used for loading ore onto ships, which then carry the ore to steelworks or to transshipment points. Most known ore docks were constructed near iron mines on the upper Great Lakes and served the lower Great Lakes. Ore docks still in existence are typically about 60 feet (18 m) wide, 80 feet (24 m) high, and vary from 900 feet (270 m) to 2,400 feet (730 m) in length. They are commonly constructed from wood, steel, reinforced concrete, or combinations of these materials.

Manganese is a ghost town and former mining community in the U.S. state of Minnesota that was inhabited between 1912 and 1960. It was built in Crow Wing County on the Cuyuna Iron Range in sections 23 and 28 of Wolford Township, about 2 miles (3 km) north of Trommald, Minnesota. After its formal dissolution, Manganese was absorbed by Wolford Township; the former town site is located between Coles Lake and Flynn Lake. First appearing in the U.S. Census of 1920 with an already dwindling population of 183, the village was abandoned by 1960.

The Marquette Iron Range is a deposit of iron ore located in Marquette County, Michigan in the United States. The towns of Ishpeming and Negaunee developed as a result of mining this deposit. A smaller counterpart of Minnesota's Mesabi Range, this is one of two iron ranges in the Lake Superior basin that are in active production as of 2018. The iron ore of the Marquette Range has been mined continuously from 1847 until the present day. Marquette Iron Range is the deposit's popular and commercial name; it is also known to geologists as the Negaunee Iron Formation.

The Animikie Group is a geologic group composed of sedimentary and metasedimentary rock, having been originally deposited between 2,500 and 1,800 million years ago during the Paleoproterozoic era, within the Animikie Basin. This group of formations is geographically divided into the Gunflint Range, the Mesabi and Vermilion ranges, and the Cuyuna Range. On the map, the Animikie Group is the dark gray northeast-trending belt which ranges from south-central Minnesota, U.S., up to Thunder Bay, Ontario, Canada. The Gunflint Iron Range is the linear black formation labeled G, the Mesabi Iron Range is the jagged black linear formation labeled F, and Cuyuna Iron Range is the two black spots labeled E. The gabbro of the Duluth Complex, intruded during the formation of the Midcontinent Rift, separates the Mesabi and Gunflint iron ranges; it is shown by the speckled area wrapping around the western end of Lake Superior.

The Jackson Mine is an open pit iron mine in Negaunee, Michigan, extracting resources from the Marquette Iron Range. The first iron mine in the Lake Superior region, Jackson Mine was designated as a Michigan State Historic Site in 1956 and listed on the National Register of Historic Places in 1971. The Lake Superior Mining Institute said, the mine "is attractive in the iron ore region of Michigan and the entire Lake Superior region, because of the fact it was here that the first discovery of iron ore was made, here the first mining was done, and from its ore the first iron was manufactured." Multiple other mines soon followed the Jackson's lead, establishing the foundation of the economy of the entire region. The mine is located northwest of intersection of Business M-28 and Cornish Town Road.

The Oliver Iron Mining Company was a mining company operating in Minnesota, United States. It was one of the most prominent companies in the early decades of mining on the Mesabi Range. As a division of U.S. Steel, Oliver dwarfed its competitors—in 1920, it operated 128 mines across the region, while its largest competitor operated only 65.

Elcor is a ghost town, or more properly, an extinct town, in the U.S. state of Minnesota that was inhabited between 1897 and 1956. It was built on the Mesabi Iron Range near the city of Gilbert in St. Louis County. Elcor was its own unincorporated community before it was abandoned and was never a neighborhood proper of the city of Gilbert. Not rating a figure in the national census, the people of Elcor were only generally considered to be citizens of Gilbert. The area where Elcor was located was annexed by Gilbert when its existing city boundaries were expanded after 1969.

The US iron and steel industry has paralleled the industry in other countries in technological developments. In the 1800s, the US switched from charcoal to coal in ore smelting, adopted the Bessemer process, and saw the rise of very large integrated steel mills. In the 20th century, the US industry successively adopted the open hearth furnace, then the basic oxygen steelmaking process. Since the American industry peaked in the 1940s and 1950s, the US industry has shifted to small mini-mills and specialty mills, using iron and steel scrap as feedstock, rather than iron ore.

The Pickands Mather Group is an American company which provides shipping of coal and other bulk commodities, and the purchase, sale, and marketing of bulk coal. Founded in 1883 as Pickands Mather & Company, it once had the second largest shipping fleet on the Great Lakes in the 1910s and 1920s. The company was purchased by the Diamond Shamrock Corporation in 1968, which in turn sold it to the Moore-McCormack Resources in 1973. Moore-McCormack sold Pickands Mather's mining interests to Cleveland-Cliffs in 1986. Moore-McCormack then spun off the Interlake Steamship Company to James Barker and Paul R. Tregurtha in 1987. Pickands Mather was sold to a management group in 1992, and continues to operate as a private company.