Lumber is wood that has been processed into uniform and useful sizes, including beams and planks or boards. Lumber is mainly used for construction framing, as well as finishing. Lumber has many uses beyond home building. Lumber is referred to as timber in the United Kingdom, Europe, Australia, and New Zealand, while in other parts of the world the term timber refers specifically to unprocessed wood fiber, such as cut logs or standing trees that have yet to be cut.

Recycling is the process of converting waste materials into new materials and objects. This concept often includes the recovery of energy from waste materials. The recyclability of a material depends on its ability to reacquire the properties it had in its original state. It is an alternative to "conventional" waste disposal that can save material and help lower greenhouse gas emissions. It can also prevent the waste of potentially useful materials and reduce the consumption of fresh raw materials, reducing energy use, air pollution and water pollution.

In marketing, a product is an object, or system, or service made available for consumer use as of the consumer demand; it is anything that can be offered to a market to satisfy the desire or need of a customer. In retailing, products are often referred to as merchandise, and in manufacturing, products are bought as raw materials and then sold as finished goods. A service is also regarded as a type of product.

Green building refers to both a structure and the application of processes that are environmentally responsible and resource-efficient throughout a building's life-cycle: from planning to design, construction, operation, maintenance, renovation, and demolition. This requires close cooperation of the contractor, the architects, the engineers, and the client at all project stages. The Green Building practice expands and complements the classical building design concerns of economy, utility, durability, and comfort. Green building also refers to saving resources to the maximum extent, including energy saving, land saving, water saving, material saving, etc., during the whole life cycle of the building, protecting the environment and reducing pollution, providing people with healthy, comfortable and efficient use of space, and being in harmony with nature. Buildings that live in harmony; green building technology focuses on low consumption, high efficiency, economy, environmental protection, integration and optimization.’

Embodied energy is the sum of all the energy required to produce any goods or services, considered as if that energy were incorporated or 'embodied' in the product itself. The concept can be useful in determining the effectiveness of energy-producing or energy saving devices, or the "real" replacement cost of a building, and, because energy-inputs usually entail greenhouse gas emissions, in deciding whether a product contributes to or mitigates global warming. One fundamental purpose for measuring this quantity is to compare the amount of energy produced or saved by the product in question to the amount of energy consumed in producing it.

Downcycling, or cascading, is the recycling of waste where the recycled material is of lower quality and functionality than the original material. Often, this is due to the accumulation of tramp elements in secondary metals, which may exclude the latter from high-quality applications. For example, steel scrap from end-of-life vehicles is often contaminated with copper from wires and tin from coating. This contaminated scrap yields a secondary steel that does not meet the specifications for automotive steel and therefore, it is mostly applied in the construction sector.

Material efficiency is a description or metric ((Mp) (the ratio of material used to the supplied material)) which refers to decreasing the amount of a particular material needed to produce a specific product. Making a usable item out of thinner stock than a prior version increases the material efficiency of the manufacturing process. Material efficiency is associated with Green building and Energy conservation, as well as other ways of incorporating Renewable resources in the building process from start to finish.

In the context of physical construction, deconstruction is the selective dismantlement of building components, specifically for reuse, repurposing, recycling, and waste management. It differs from demolition where a site is cleared of its building by the most expedient means. Deconstruction has also been defined as "construction in reverse". Deconstruction requires a substantially higher degree of hands-on labor than does traditional demolition, but as such provides a viable platform for unskilled or unemployed workers to receive job skills training. The process of dismantling structures is an ancient activity that has been revived by the growing fields of sustainable and green building.

Glass recycling is the processing of waste glass into usable products. Glass that is crushed or imploded and ready to be remelted is called cullet. There are two types of cullet: internal and external. Internal cullet is composed of defective products detected and rejected by a quality control process during the industrial process of glass manufacturing, transition phases of product changes and production offcuts. External cullet is waste glass that has been collected or reprocessed with the purpose of recycling. External cullet is classified as waste. The word "cullet", when used in the context of end-of-waste, will always refer to external cullet.

Reuse is the action or practice of using an item, whether for its original purpose or to fulfill a different function. It should be distinguished from recycling, which is the breaking down of used items to make raw materials for the manufacture of new products. Reuse—by taking, but not reprocessing, previously used items—helps save time, money, energy and resources. In broader economic terms, it can make quality products available to people and organizations with limited means, while generating jobs and business activity that contribute to the economy.

An urban mine is the stockpile of rare metals in the discarded waste electrical and electronic equipment (WEEE) of a society. Urban mining is the process of recovering these rare metals through mechanical and chemical treatments. In 1997, recycled gold accounted for approximately 20% of the 2700 tons of gold supplied to the market.

Cradle-to-cradle design is a biomimetic approach to the design of products and systems that models human industry on nature's processes, where materials are viewed as nutrients circulating in healthy, safe metabolisms. The term itself is a play on the popular corporate phrase "cradle to grave", implying that the C2C model is sustainable and considerate of life and future generations—from the birth, or "cradle", of one generation to the next generation, versus from birth to death, or "grave", within the same generation.

Upcycling, also known as creative reuse, is the process of transforming by-products, waste materials, useless, or unwanted products into new materials or products perceived to be of greater quality, such as artistic value or environmental value.

Environmentally sustainable design is the philosophy of designing physical objects, the built environment, and services to comply with the principles of ecological sustainability and also aimed at improving the health and comfort of occupants in a building. Sustainable design seeks to reduce negative impacts on the environment, the health and well-being of building occupants, thereby improving building performance. The basic objectives of sustainability are to reduce the consumption of non-renewable resources, minimize waste, and create healthy, productive environments.

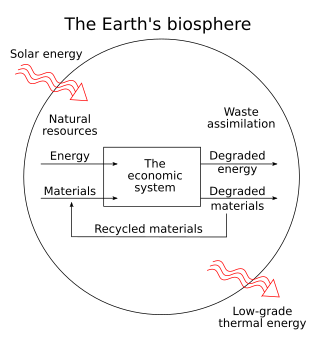

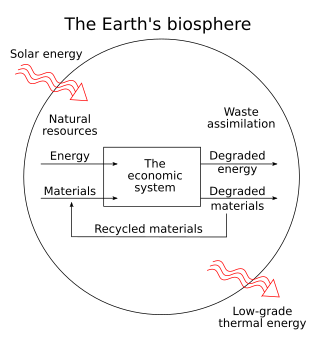

A circular economy is a model of resource production and consumption in any economy that involves sharing, leasing, reusing, repairing, refurbishing, and recycling existing materials and products for as long as possible. The concept aims to tackle global challenges such as climate change, biodiversity loss, waste, and pollution by emphasizing the design-based implementation of the three base principles of the model. The main three principles required for the transformation to a circular economy are: designing out waste and pollution, keeping products and materials in use, and regenerating natural systems. CE is defined in contradistinction to the traditional linear economy. The idea and concepts of a circular economy have been studied extensively in academia, business, and government over the past ten years. It has been gaining popularity because it can help to minimize carbon emissions and the consumption of raw materials, open up new market prospects, and, principally, increase the sustainability of consumption.

Sustainable products are products who are either sustainability sourced, manufactured or processed that provide environmental, social and economic benefits while protecting public health and environment over their whole life cycle, from the extraction of raw materials until the final disposal.

Sustainable furniture design and sustainable interior design is the design of a habitable interior using furniture, finishes, and equipment while addressing the environmental impact of products and building materials used. By considering the life-cycle impact of each step, from raw material through the manufacturing process and through the product's end of life, sustainable choices can be made. Design considerations can include using recycled materials in the manufacturing process, reutilizing found furniture and using products that can be disassembled and recycled or reclaimed after their useful life. Another method of approach is working with local materials and vendors as a source for raw materials or products. Sustainable furniture design strives to create a closed-loop cycle in which materials and products are perpetually recycled so as to avoid disposal in landfills.

Resource recovery is using wastes as an input material to create valuable products as new outputs. The aim is to reduce the amount of waste generated, thereby reducing the need for landfill space, and optimising the values created from waste. Resource recovery delays the need to use raw materials in the manufacturing process. Materials found in municipal solid waste, construction and demolition waste, commercial waste and industrial wastes can be used to recover resources for the manufacturing of new materials and products. Plastic, paper, aluminium, glass and metal are examples of where value can be found in waste.

Ecopreneurship is a term coined to represent the process of principles of entrepreneurship being applied to create businesses that solve environmental problems or operate sustainably. The term began to be widely used in the 1990s, and it is otherwise referred to as "environmental entrepreneurship." In the book Merging Economic and Environmental Concerns Through Ecopreneurship, written by Gwyn Schuyler in 1998, ecopreneurs are defined as follows:

"Ecopreneurs are entrepreneurs whose business efforts are not only driven by profit, but also by a concern for the environment. Ecopreneurship, also known as environmental entrepreneurship and eco-capitalism, is becoming more widespread as a new market-based approach to identifying opportunities for improving environmental quality and capitalizing upon them in the private sector for profit. "

Sustainable Materials Management is a systemic approach to using and reusing materials more productively over their entire lifecycles. It represents a change in how a society thinks about the use of natural resources and environmental protection. By looking at a product's entire lifecycle new opportunities can be found to reduce environmental impacts, conserve resources, and reduce costs.