Related Research Articles

In physics, cryogenics is the production and behaviour of materials at very low temperatures.

Vulcanization is a range of processes for hardening rubbers. The term originally referred exclusively to the treatment of natural rubber with sulfur, which remains the most common practice. It has also grown to include the hardening of other (synthetic) rubbers via various means. Examples include silicone rubber via room temperature vulcanizing and chloroprene rubber (neoprene) using metal oxides.

An elastomer is a polymer with viscoelasticity and with weak intermolecular forces, generally low Young's modulus and high failure strain compared with other materials. The term, a portmanteau of elastic polymer, is often used interchangeably with rubber, although the latter is preferred when referring to vulcanisates. Each of the monomers which link to form the polymer is usually a compound of several elements among carbon, hydrogen, oxygen and silicon. Elastomers are amorphous polymers maintained above their glass transition temperature, so that considerable molecular reconformation, without breaking of covalent bonds, is feasible. At ambient temperatures, such rubbers are thus relatively compliant and deformable. Their primary uses are for seals, adhesives and molded flexible parts. Application areas for different types of rubber are manifold and cover segments as diverse as tires, soles for shoes, and damping and insulating elements. The importance of these rubbers can be judged from the fact that global revenues are forecast to rise to US$56 billion in 2020.

An O-ring, also known as a packing or a toric joint, is a mechanical gasket in the shape of a torus; it is a loop of elastomer with a round cross-section, designed to be seated in a groove and compressed during assembly between two or more parts, forming a seal at the interface.

A power cable is an electrical cable, an assembly of one or more electrical conductors, usually held together with an overall sheath. The assembly is used for transmission of electrical power. Power cables may be installed as permanent wiring within buildings, buried in the ground, run overhead, or exposed. Power cables that are bundled inside thermoplastic sheathing and that are intended to be run inside a building are known as NM-B.

An electroactive polymer (EAP) is a polymer that exhibits a change in size or shape when stimulated by an electric field. The most common applications of this type of material are in actuators and sensors. A typical characteristic property of an EAP is that they will undergo a large amount of deformation while sustaining large forces.

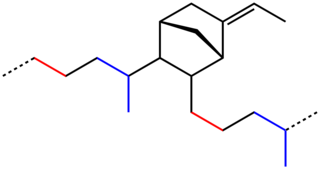

EPDM rubber is a type of synthetic rubber that is used in many applications. Dienes used in the manufacture of EPDM rubbers are ethylidene norbornene (ENB), dicyclopentadiene (DCPD), and vinyl norbornene (VNB). 4-8% of these monomers are typically used.

Hot-melt adhesive (HMA), also known as hot glue, is a form of thermoplastic adhesive that is commonly sold as solid cylindrical sticks of various diameters designed to be applied using a hot glue gun. The gun uses a continuous-duty heating element to melt the plastic glue, which the user pushes through the gun either with a mechanical trigger mechanism on the gun, or with direct finger pressure. The glue squeezed out of the heated nozzle is initially hot enough to burn and even blister skin. The glue is sticky when hot, and solidifies in a few seconds to one minute. Hot-melt adhesives can also be applied by dipping or spraying, and are popular with hobbyists and crafters both for affixing and as an inexpensive alternative to resin casting.

Silicone rubber is an elastomer composed of silicone—itself a polymer—containing silicon together with carbon, hydrogen, and oxygen. Silicone rubbers are widely used in industry, and there are multiple formulations. Silicone rubbers are often one- or two-part polymers, and may contain fillers to improve properties or reduce cost.

Vibration isolation is the process of isolating an object, such as a piece of equipment, from the source of vibrations.

Injection molding of liquid silicone rubber (LSR) is a process to produce pliable, durable parts in high volume.

Carbon nanotubes (CNTs) are cylinders of one or more layers of graphene (lattice). Diameters of single-walled carbon nanotubes (SWNTs) and multi-walled carbon nanotubes (MWNTs) are typically 0.8 to 2 nm and 5 to 20 nm, respectively, although MWNT diameters can exceed 100 nm. CNT lengths range from less than 100 nm to 0.5 m.

Dielectric elastomers (DEs) are smart material systems that produce large strains. They belong to the group of electroactive polymers (EAP). DE actuators (DEA) transform electric energy into mechanical work. They are lightweight and have a high elastic energy density. They have been investigated since the late 1990s. Many prototype applications exist. Every year, conferences are held in the US and Europe.

Polymer engineering is generally an engineering field that designs, analyses, and modifies polymer materials. Polymer engineering covers aspects of the petrochemical industry, polymerization, structure and characterization of polymers, properties of polymers, compounding and processing of polymers and description of major polymers, structure property relations and applications.

A zinc oxide nanorod sensor or ZnO nanorod sensor is an electronic or optical device detecting presence of certain gas or liquid molecules in the ambient atmosphere. The sensor exploits enhanced surface area intrinsic to all nano-sized materials, including ZnO nanorods. Adsorption of molecules on the nanorods can be detected through variation of the nanorods' properties, such as photoluminescence, electrical conductivity, vibration frequency, mass, etc. The simplest and thus most popular way is to pass electrical current through the nanorods and observe its changes upon exposure to gas. Synthesis can be obtained by a hydrothermal method using 1:1 Molar solution of hexamine and Zinc nitrate solution kept together for 56 hours in an autoclave at 60-70 degree Celsius.

Quantum tunnelling composites (QTCs) are composite materials of metals and non-conducting elastomeric binder, used as pressure sensors. They use quantum tunnelling: without pressure, the conductive elements are too far apart to conduct electricity; when pressure is applied, they move closer and electrons can tunnel through the insulator. The effect is far more pronounced than would be expected from classical (non-quantum) effects alone, as classical electrical resistance is linear (proportional to distance), while quantum tunnelling is exponential with decreasing distance, allowing the resistance to change by a factor of up to 1012 between pressured and unpressured states.

Electronic skin refers to flexible, stretchable and self-healing electronics that are able to mimic functionalities of human or animal skin. The broad class of materials often contain sensing abilities that are intended to reproduce the capabilities of human skin to respond to environmental factors such as changes in heat and pressure.

Magnetorheological elastomers (MREs) are a class of solids that consist of polymeric matrix with embedded micro- or nano-sized ferromagnetic particles such as carbonyl iron. As a result of this composite microstructure, the mechanical properties of these materials can be controlled by the application of magnetic field.

A conductive elastomer is a form of elastomer, often natural rubber or other rubber substitute, that is manufactured to conduct electricity. This is commonly accomplished by distributing carbon or other conductive particles throughout the raw material prior to setting it. Carbon black and silica are common additives to induce conductivity in elastomers. Silica has been studied more so than other additives due to its low cost however, its conductance is also lower. These additives can not only enable conductance but can increase the mechanical properties of the elastomer.

A stretch sensor is a sensor which can be used to measure deformation and stretching forces such as tension or bending. They are usually made from a material that is itself soft and stretchable.

References

- 1 2 Lalli, Jennifer & Claus, Richard & Hill, Andrea & Mecham, Jeffrey & Davis, Bradley & Subramanayan, Sumitra & Goff, R.. (2005). Commercial applications of Metal rubber (TM). Proceedings of SPIE - The International Society for Optical Engineering. 5762. 10.1117/12.606788.

- ↑ "Metal rubber - ExtremeTech". www.extremetech.com. Retrieved 2022-06-23.

- ↑ "Metal rubber". prezi.com. Retrieved 2022-06-23.

- ↑ "Lightweight Metal rubber Wire and Cable for Space Power Systems | SBIR.gov". www.sbir.gov. Retrieved 2022-06-23.