Related Research Articles

A liposome is a small artificial vesicle, spherical in shape, having at least one lipid bilayer. Due to their hydrophobicity and/or hydrophilicity, biocompatibility, particle size and many other properties, liposomes can be used as drug delivery vehicles for administration of pharmaceutical drugs and nutrients, such as lipid nanoparticles in mRNA vaccines, and DNA vaccines. Liposomes can be prepared by disrupting biological membranes.

Microencapsulation is a process in which tiny particles or droplets are surrounded by a coating to give small capsules, with useful properties. In general, it is used to incorporate food ingredients, enzymes, cells or other materials on a micro metric scale. Microencapsulation can also be used to enclose solids, liquids, or gases inside a micrometric wall made of hard or soft soluble film, in order to reduce dosing frequency and prevent the degradation of pharmaceuticals.

Dendrimers are highly ordered, branched polymeric molecules. Synonymous terms for dendrimer include arborols and cascade molecules. Typically, dendrimers are symmetric about the core, and often adopt a spherical three-dimensional morphology. The word dendron is also encountered frequently. A dendron usually contains a single chemically addressable group called the focal point or core. The difference between dendrons and dendrimers is illustrated in the top figure, but the terms are typically encountered interchangeably.

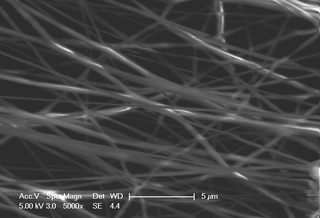

Electrospinning is a fiber production method that uses electric force to draw charged threads of polymer solutions or polymer melts up to fiber diameters in the order of some hundred nanometers. Electrospinning shares characteristics of both electrospraying and conventional solution dry spinning of fibers. The process does not require the use of coagulation chemistry or high temperatures to produce solid threads from solution. This makes the process particularly suited to the production of fibers using large and complex molecules. Electrospinning from molten precursors is also practiced; this method ensures that no solvent can be carried over into the final product.

An artificial cell, synthetic cell or minimal cell is an engineered particle that mimics one or many functions of a biological cell. Often, artificial cells are biological or polymeric membranes which enclose biologically active materials. As such, liposomes, polymersomes, nanoparticles, microcapsules and a number of other particles can qualify as artificial cells.

Microparticles are particles between 0.1 and 100 μm in size. Commercially available microparticles are available in a wide variety of materials, including ceramics, glass, polymers, and metals. Microparticles encountered in daily life include pollen, sand, dust, flour, and powdered sugar.

Targeted drug delivery, sometimes called smart drug delivery, is a method of delivering medication to a patient in a manner that increases the concentration of the medication in some parts of the body relative to others. This means of delivery is largely founded on nanomedicine, which plans to employ nanoparticle-mediated drug delivery in order to combat the downfalls of conventional drug delivery. These nanoparticles would be loaded with drugs and targeted to specific parts of the body where there is solely diseased tissue, thereby avoiding interaction with healthy tissue. The goal of a targeted drug delivery system is to prolong, localize, target and have a protected drug interaction with the diseased tissue. The conventional drug delivery system is the absorption of the drug across a biological membrane, whereas the targeted release system releases the drug in a dosage form. The advantages to the targeted release system is the reduction in the frequency of the dosages taken by the patient, having a more uniform effect of the drug, reduction of drug side-effects, and reduced fluctuation in circulating drug levels. The disadvantage of the system is high cost, which makes productivity more difficult, and the reduced ability to adjust the dosages.

Pharmaceutical formulation, in pharmaceutics, is the process in which different chemical substances, including the active drug, are combined to produce a final medicinal product. The word formulation is often used in a way that includes dosage form.

The ouzo effect is a milky oil-in-water emulsion that is formed when water is added to ouzo and other anise-flavored liqueurs and spirits, such as pastis, rakı, arak, sambuca and absinthe. Such emulsions occur with only minimal mixing and are highly stable.

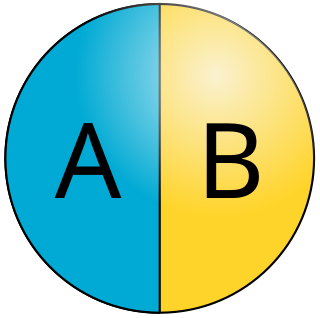

Janus particles are special types of nanoparticles or microparticles whose surfaces have two or more distinct physical properties. This unique surface of Janus particles allows two different types of chemistry to occur on the same particle. The simplest case of a Janus particle is achieved by dividing the particle into two distinct parts, each of them either made of a different material, or bearing different functional groups. For example, a Janus particle may have one-half of its surface composed of hydrophilic groups and the other half hydrophobic groups, the particles might have two surfaces of different color, fluorescence, or magnetic properties. This gives these particles unique properties related to their asymmetric structure and/or functionalization.

A nanogel is a polymer-based, crosslinked hydrogel particle on the sub-micron scale. These complex networks of polymers present a unique opportunity in the field of drug delivery at the intersection of nanoparticles and hydrogel synthesis. Nanogels can be natural, synthetic, or a combination of the two and have a high degree of tunability in terms of their size, shape, surface functionalization, and degradation mechanisms. Given these inherent characteristics in addition to their biocompatibility and capacity to encapsulate small drugs and molecules, nanogels are a promising strategy to treat disease and dysfunction by serving as delivery vehicles capable of navigating across challenging physiological barriers within the body.

Nano-scaffolding is a medical process used to regrow tissue and bone, including limbs and organs. The nano-scaffold is a three-dimensional structure composed of polymer fibers very small that are scaled from a Nanometer scale. Developed by the American military, the medical technology uses a microscopic apparatus made of fine polymer fibers called a scaffold. Damaged cells grip to the scaffold and begin to rebuild missing bone and tissue through tiny holes in the scaffold. As tissue grows, the scaffold is absorbed into the body and disappears completely.

In polymer chemistry, in situ polymerization is a preparation method that occurs "in the polymerization mixture" and is used to develop polymer nanocomposites from nanoparticles. There are numerous unstable oligomers (molecules) which must be synthesized in situ for use in various processes. The in situ polymerization process consists of an initiation step followed by a series of polymerization steps, which results in the formation of a hybrid between polymer molecules and nanoparticles. Nanoparticles are initially spread out in a liquid monomer or a precursor of relatively low molecular weight. Upon the formation of a homogeneous mixture, initiation of the polymerization reaction is carried out by addition of an adequate initiator, which is exposed to a source of heat, radiation, etc. After the polymerization mechanism is completed, a nanocomposite is produced, which consists of polymer molecules bound to nanoparticles.

Nano spray dryers refer to using spray drying to create particles in the nanometer range. Spray drying is a gentle method for producing powders with a defined particle size out of solutions, dispersions, and emulsions which is widely used for pharmaceuticals, food, biotechnology, and other industrial materials synthesis.

Cell encapsulation is a possible solution to graft rejection in tissue engineering applications. Cell microencapsulation technology involves immobilization of cells within a polymeric semi-permeable membrane. It permits the bidirectional diffusion of molecules such as the influx of oxygen, nutrients, growth factors etc. essential for cell metabolism and the outward diffusion of waste products and therapeutic proteins. At the same time, the semi-permeable nature of the membrane prevents immune cells and antibodies from destroying the encapsulated cells, regarding them as foreign invaders.

Nanoparticles for drug delivery to the brain is a method for transporting drug molecules across the blood–brain barrier (BBB) using nanoparticles. These drugs cross the BBB and deliver pharmaceuticals to the brain for therapeutic treatment of neurological disorders. These disorders include Parkinson's disease, Alzheimer's disease, schizophrenia, depression, and brain tumors. Part of the difficulty in finding cures for these central nervous system (CNS) disorders is that there is yet no truly efficient delivery method for drugs to cross the BBB. Antibiotics, antineoplastic agents, and a variety of CNS-active drugs, especially neuropeptides, are a few examples of molecules that cannot pass the BBB alone. With the aid of nanoparticle delivery systems, however, studies have shown that some drugs can now cross the BBB, and even exhibit lower toxicity and decrease adverse effects throughout the body. Toxicity is an important concept for pharmacology because high toxicity levels in the body could be detrimental to the patient by affecting other organs and disrupting their function. Further, the BBB is not the only physiological barrier for drug delivery to the brain. Other biological factors influence how drugs are transported throughout the body and how they target specific locations for action. Some of these pathophysiological factors include blood flow alterations, edema and increased intracranial pressure, metabolic perturbations, and altered gene expression and protein synthesis. Though there exist many obstacles that make developing a robust delivery system difficult, nanoparticles provide a promising mechanism for drug transport to the CNS.

Interfacial polymerization is a type of step-growth polymerization in which polymerization occurs at the interface between two immiscible phases, resulting in a polymer that is constrained to the interface. There are several variations of interfacial polymerization, which result in several types of polymer topologies, such as ultra-thin films, nanocapsules, and nanofibers, to name just a few.

Nanocomposite hydrogels are nanomaterial-filled, hydrated, polymeric networks that exhibit higher elasticity and strength relative to traditionally made hydrogels. A range of natural and synthetic polymers are used to design nanocomposite network. By controlling the interactions between nanoparticles and polymer chains, a range of physical, chemical, and biological properties can be engineered. The combination of organic (polymer) and inorganic (clay) structure gives these hydrogels improved physical, chemical, electrical, biological, and swelling/de-swelling properties that cannot be achieved by either material alone. Inspired by flexible biological tissues, researchers incorporate carbon-based, polymeric, ceramic and/or metallic nanomaterials to give these hydrogels superior characteristics like optical properties and stimulus-sensitivity which can potentially be very helpful to medical and mechanical fields.

Nanoparticle drug delivery systems are engineered technologies that use nanoparticles for the targeted delivery and controlled release of therapeutic agents. The modern form of a drug delivery system should minimize side-effects and reduce both dosage and dosage frequency. Recently, nanoparticles have aroused attention due to their potential application for effective drug delivery.

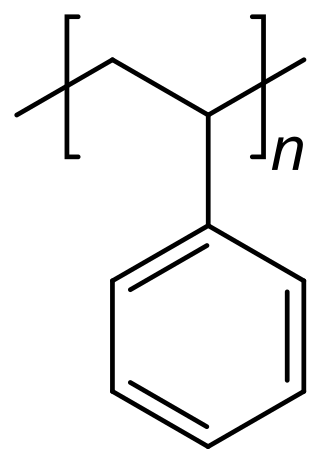

Polystyrene is a synthetic hydrocarbon polymer that is widely adaptive and can be used for a variety of purposes in drug delivery. These methods include polystyrene microspheres, nanoparticles, and solid foams. In the biomedical engineering field, these methods assist researchers in drug delivery, diagnostics, and imaging strategies.

References

- 1 2 3 4 5 6 7 8 9 Ezhilarasi, P. N.; Karthik, P.; Chhanwal, N.; Anandharamakrishnan, C. (2012). "Nanoencapsulation Techniques for Food Bioactive Components: A Review". Food and Bioprocess Technology. 6 (3): 628–47. doi:10.1007/s11947-012-0944-0. S2CID 98381808.

- ↑ Vartholomeos, P.; Fruchard, M.; Ferreira, A.; Mavroidis, C. (2011). "MRI-Guided Nanorobotic Systems for Therapeutic and Diagnostic Applications". Annu Rev Biomed Eng. 13: 157–84. doi:10.1146/annurev-bioeng-071910-124724. PMID 21529162. S2CID 32852758.

- ↑ Vert, Michel; Doi, Yoshiharu; Hellwich, Karl-Heinz; Hess, Michael; Hodge, Philip; Kubisa, Przemyslaw; Rinaudo, Marguerite; Schué, François (2012). "Terminology for biorelated polymers and applications (IUPAC Recommendations 2012)" (PDF). Pure and Applied Chemistry . 84 (2): 377–410. doi:10.1351/PAC-REC-10-12-04. S2CID 98107080.

- 1 2 3 4 5 6 7 8 Nagavarma, B V N; Yadav, Hemant K S; Ayaz, A; Vasudha, L S; Shivakumar, H G (2012). "Different Techniques for Preparation of Polymeric Nanoparticles – A Review" (PDF). Asian Journal of Pharmaceutical and Clinical Research. 5 (Suppl 3): 16–23.

- 1 2 3 4 5 6 Mora-Huertas, C.E.; Fessi, H.; Elaissari, A. (2010). "Polymer-based nanocapsules for drug delivery". International Journal of Pharmaceutics. 385 (1–2): 113–42. doi:10.1016/j.ijpharm.2009.10.018. PMID 19825408.

- 1 2 Shimoni, Olga; Yan, Yan; Wang, Yajun; Caruso, Frank (2013). "Shape-Dependent Cellular Processing of Polyelectrolyte Capsules". ACS Nano. 7 (1): 522–30. doi: 10.1021/nn3046117 . PMID 23234433.

- Belle Dumé (December 21, 2012). "Nanocapsule shape matters for drug delivery". Nanotechweb.

- 1 2 3 4 5 6 7 Timko, Brian P.; Whitehead, Kathryn; Gao, Weiwei; Kohane, Daniel S.; Farokhzad, Omid; Anderson, Daniel; Langer, Robert (2011). "Advances in Drug Delivery". Annual Review of Materials Research . 41: 1–20. Bibcode:2011AnRMS..41....1T. doi:10.1146/annurev-matsci-062910-100359.

- ↑ Long, Li-xia; Yuan, Xu-bo; Chang, Jiang; Zhang, Zhi-hua; Gu, Ming-qi; Song, Tian-Tian; Xing, Ying; Yuan, Xiao-yan; et al. (2012). "Self-assembly of polylactic acid and cholesterol-modified dextran into hollow nanocapsules". Carbohydrate Polymers. 87 (4): 2630–7. doi:10.1016/j.carbpol.2011.11.032.

- ↑ "Dictionary of nanotechnology - Nanoprecipitation".

- ↑ http://www.rpi.edu/dept/chem-eng/Biotech-Environ/LYO/%5B%5D

- ↑ Pietersen, Alexandra; Noteborn, Mathieu H. M. (2000). "Apoptin". Cancer Gene Therapy: Past Achievements and Future Challenges. Advances in Experimental Medicine and Biology. Vol. 465. pp. 153–61. doi:10.1007/0-306-46817-4_14. ISBN 978-0-306-46817-9. PMID 10810623.

- 1 2 Zhao, Muxun; Hu, Biliang; Gu, Zhen; Joo, Kye-Il; Wang, Pin; Tang, Yi (2013). "Degradable polymeric nanocapsule for efficient intracellular delivery of a high molecular weight tumor-selective protein complex". Nano Today. 8: 11–20. doi:10.1016/j.nantod.2012.12.003.

- Bill Kisliuk (February 7, 2013). "Nanocapsules Battle Cancer without Harming Healthy Cells". SciTech Daily.

- ↑ Liu, Yang; Du, Juanjuan; Yan, Ming; Lau, Mo Yin; Hu, Jay; Han, Hui; Yang, Otto O.; Liang, Sheng; et al. (2013). "Biomimetic enzyme nanocomplexes and their use as antidotes and preventive measures for alcohol intoxication". Nature Nanotechnology. 8 (3): 187–92. Bibcode:2013NatNa...8..187L. doi:10.1038/nnano.2012.264. PMC 3670615 . PMID 23416793.

- Mike Orcutt (February 17, 2013). "Nanocapsules Sober Up Drunken Mice". MIT Technology Review. Archived from the original on 2013-02-17.

- ↑ Blaiszik, B.J.; Sottos, N.R.; White, S.R. (2008). "Nanocapsules for self-healing materials". Composites Science and Technology. 68 (3–4): 978–86. doi:10.1016/j.compscitech.2007.07.021.