Adhesive, also known as glue, cement, mucilage, or paste, is any non-metallic substance applied to one or both surfaces of two separate items that binds them together and resists their separation.

Bakelite, formally polyoxybenzylmethyleneglycolanhydride, is a thermosetting phenol formaldehyde resin, formed from a condensation reaction of phenol with formaldehyde. The first plastic made from synthetic components, it was developed by Leo Baekeland in Yonkers, New York, in 1907, and patented on December 7, 1909.

Plywood is a composite material manufactured from thin layers, or "plies", of wood veneer that are glued together with adjacent layers, having their wood grain rotated up to 90° to one another. It is an engineered wood from the family of manufactured boards, which include medium-density fibreboard (MDF), oriented strand board (OSB), and particle board.

Lamination is the technique/process of manufacturing a material in multiple layers, so that the composite material achieves improved strength, stability, sound insulation, appearance, or other properties from the use of the differing materials, such as plastic. A laminate is a permanently assembled object created using heat, pressure, welding, or adhesives. Various coating machines, machine presses and calendering equipment are used.

Glued laminated timber, commonly referred to as glulam, is a type of structural engineered wood product constituted by layers of dimensional lumber bonded together with durable, moisture-resistant structural adhesives so that all of the grain runs parallel to the longitudinal axis. In North America, the material providing the laminations is termed laminating stock or lamstock.

Araldite is a registered trademark of Huntsman Advanced Materials referring to their range of engineering and structural epoxy, acrylic, and polyurethane adhesives. Swiss manufacturers originally launched Araldite DIY adhesive products in 1946. The first batches of Araldite epoxy resins, for which the brand is best known, were made in Duxford, England in 1950.

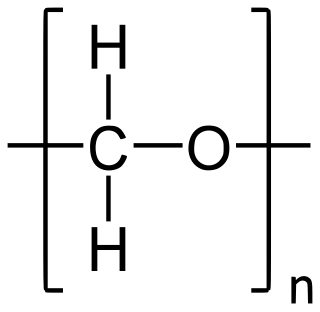

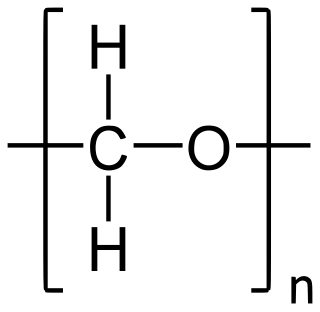

Polyoxymethylene (POM), also known as acetal, polyacetal, and polyformaldehyde, is an engineering thermoplastic used in precision parts requiring high stiffness, low friction, and excellent dimensional stability. As with many other synthetic polymers, it is produced by different chemical firms with slightly different formulas and sold variously by such names as Delrin, Kocetal, Ultraform, Celcon, Ramtal, Duracon, Kepital, Polypenco, Tenac and Hostaform.

Urea-formaldehyde (UF), also known as urea-methanal, so named for its common synthesis pathway and overall structure, is a nontransparent thermosetting resin or polymer. It is produced from urea and formaldehyde. These resins are used in adhesives, plywood, particle board, medium-density fibreboard (MDF), and molded objects. In agriculture, urea-formaldehyde compounds are one of the most commonly used types of slow-release fertilizer.

Wood glue is an adhesive used to tightly bond pieces of wood together. Many substances have been used as glues. Traditionally animal proteins like casein from milk or collagen from animal hides and bones were boiled down to make early glues. They worked by solidifying as they dried. Later, glues were made from plant starches like flour or potato starch. When combined with water and heated, the starch gelatinizes and forms a sticky paste as it dries. Plant-based glues were common for books and paper products, though they can break down more easily over time compared to animal-based glues. Examples of modern wood glues include polyvinyl acetate (PVA) and epoxy resins. Some resins used in producing composite wood products may contain formaldehyde. As of 2021, “the wood panel industry uses almost 95% of synthetic petroleum-derived thermosetting adhesives, mainly based on urea, phenol, and melamine, among others”.

The de Havilland DH.104 Dove is a British short-haul airliner developed and manufactured by de Havilland. The design, which was a monoplane successor to the pre-war Dragon Rapide biplane, came about from the Brabazon Committee report which, amongst other aircraft types, called for a British-designed short-haul feeder for airlines.

Redux is the generic name of a family of phenol–formaldehyde/polyvinyl–formal adhesives developed by Aero Research Limited (ARL) at Duxford, UK, in the 1940s, subsequently produced by Ciba (ARL). The brand name is now also used for a range of epoxy and bismaleimide adhesives manufactured by Hexcel. The name is a contraction of REsearch at DUXford.

Aero Research Limited (ARL) was a British company that pioneered several new adhesives, intended initially for the aeronautical industry.

Aerolite is a urea-formaldehyde gap filling adhesive which is water- and heat-resistant. It is used in large quantities by the chipboard industry and also by wooden boat builders for its high strength and durability. It is also used in joinery, veneering and general woodwork assembly. Aerolite has also been used for wooden aircraft construction, and a properly made Aerolite joint is said to be three times stronger than spruce wood.

A thermoset polymer matrix is a synthetic polymer reinforcement where polymers act as binder or matrix to secure in place incorporated particulates, fibres or other reinforcements. They were first developed for structural applications, such as glass-reinforced plastic radar domes on aircraft and graphite-epoxy payload bay doors on the Space Shuttle.

Hordern-Richmond was a British aeronautical engineering company that traded between 1937 and c. 1990.

de Havilland Propellers was established in 1935, as a division of the de Havilland Aircraft company when that company acquired a licence from the Hamilton Standard company of America for the manufacture of variable-pitch propellers at a cost of about £20,000. Licence negotiations were completed in June 1934.

Tego film is an adhesive sheet used in the manufacture of waterproof plywood. It is applied dry and cured by heat, which allows for high-quality laminates that are free from internal voids and warping. Tego film plywood products were used in aircraft manufacture in Germany during World War II, and the loss of the plant during a 1943 bombing raid was a serious blow to several aircraft projects. Tego film was an invention of the Essen, Germany, firm of Th. Goldschmidt AG later Evonik Industries ).

Duramold is a composite material process developed by Virginius E. Clark. Birch or poplar plies are impregnated with phenolic resin and laminated together in a mold under heat and pressure for use as a lightweight structural material. Similar to plywood, Duramold and other lightweight composite materials like the similar Haskelite were considered critical during periods of material shortage in World War II, replacing scarce materials such as aluminum alloys and steel.

Mark Gillachrist Marlborough Pryor was a British biologist, who was Senior Tutor and Fellow of Trinity College, Cambridge.

Formvar refers to any of several thermoplastic resins that are polyvinyl formals, which are polymers formed from polyvinyl alcohol and formaldehyde as copolymers with polyvinyl acetate. They are typically used as coatings, adhesives, and molding materials.