The open-design movement involves the development of physical products, machines and systems through use of publicly shared design information. This includes the making of both free and open-source software (FOSS) as well as open-source hardware. The process is generally facilitated by the Internet and often performed without monetary compensation. The goals and philosophy of the movement are identical to that of the open-source movement, but are implemented for the development of physical products rather than software. Open design is a form of co-creation, where the final product is designed by the users, rather than an external stakeholder such as a private company.

A fab lab is a small-scale workshop offering (personal) digital fabrication.

Open-source hardware (OSH) consists of physical artifacts of technology designed and offered by the open-design movement. Both free and open-source software (FOSS) and open-source hardware are created by this open-source culture movement and apply a like concept to a variety of components. It is sometimes, thus, referred to as FOSH. The term usually means that information about the hardware is easily discerned so that others can make it – coupling it closely to the maker movement. Hardware design, in addition to the software that drives the hardware, are all released under free/libre terms. The original sharer gains feedback and potentially improvements on the design from the FOSH community. There is now significant evidence that such sharing can drive a high return on investment for the scientific community.

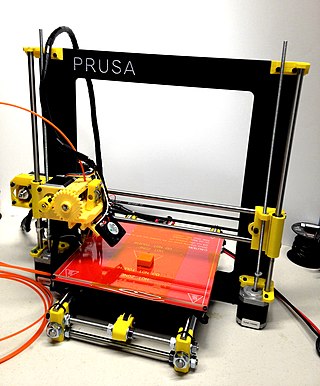

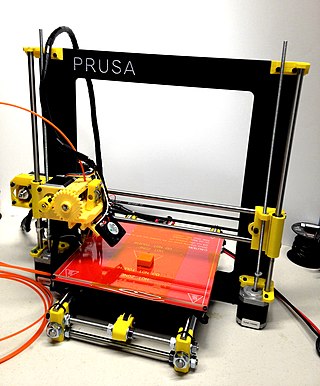

RepRap is a project to develop a low-cost 3D printer that can print most of its own components. As an open design, all of the designs produced by the project are released under a free software license, the GNU General Public License.

Laboratory automation is a multi-disciplinary strategy to research, develop, optimize and capitalize on technologies in the laboratory that enable new and improved processes. Laboratory automation professionals are academic, commercial and government researchers, scientists and engineers who conduct research and develop new technologies to increase productivity, elevate experimental data quality, reduce lab process cycle times, or enable experimentation that otherwise would be impossible.

DIYbio is an informal umbrella organization for individuals and local groups active in do-it-yourself biology, encompassing both a website and an email list. It serves as a network of individuals from around the globe that aims to help make biology a worthwhile pursuit for citizen scientists, biohackers, amateur biologists, and do-it-yourself biological engineers who value openness and safety. It was founded by Jason Bobe and Mackenzie Cowell in 2008.

Do-it-yourself biology is a biotechnological social movement in which individuals, communities, and small organizations study biology and life science using the same methods as traditional research institutions. DIY biology is primarily undertaken by individuals with limited research training from academia or corporations, who then mentor and oversee other DIY biologists with little or no formal training. This may be done as a hobby, as a not-for-profit endeavor for community learning and open-science innovation, or for profit, to start a business.

OpenSCAD is a free software application for creating solid 3D computer-aided design (CAD) objects. It is a script-only based modeller that uses its own description language; the 3D preview can be manipulated interactively, but cannot be interactively modified in 3D. Instead, an OpenSCAD script specifies geometric primitives and defines how they are modified and combined to render a 3D model. As such, the program performs constructive solid geometry (CSG). OpenSCAD is available for Windows, Linux, and macOS.

The maker culture is a contemporary subculture representing a technology-based extension of DIY culture that intersects with hardware-oriented parts of hacker culture and revels in the creation of new devices as well as tinkering with existing ones. The maker culture in general supports open-source hardware. Typical interests enjoyed by the maker culture include engineering-oriented pursuits such as electronics, robotics, 3-D printing, and the use of computer numeric control tools, as well as more traditional activities such as metalworking, woodworking, and, mainly, its predecessor, traditional arts and crafts.

Thingiverse is a website dedicated to the sharing of user-created digital design files. Providing primarily free, open-source hardware designs licensed under the GNU General Public License or Creative Commons licenses, the site allows contributors to select a user license type for the designs that they share. 3D printers, laser cutters, milling machines and many other technologies can be used to physically create the files shared by the users on Thingiverse.

Open Source Ecology (OSE) is a network of farmers, engineers, architects and supporters, whose main goal is the eventual manufacturing of the Global Village Construction Set (GVCS). As described by Open Source Ecology "the GVCS is an open technological platform that allows for the easy fabrication of the 50 types of industrial machines that it takes to build a small civilization with modern comforts". Groups in Oberlin, Ohio, Pennsylvania, New York and California are developing blueprints, and building prototypes in order to test them on the Factor e Farm in rural Missouri. 3D-Print.com reports that OSE has been experimenting with RepRap 3-D printers, as suggested by academics for sustainable development.

Distributed manufacturing also known as distributed production, cloud producing, distributed digital manufacturing, and local manufacturing is a form of decentralized manufacturing practiced by enterprises using a network of geographically dispersed manufacturing facilities that are coordinated using information technology. It can also refer to local manufacture via the historic cottage industry model, or manufacturing that takes place in the homes of consumers.

Joshua M. Pearce is an academic engineer at Western University and Michigan Tech known for his work on protocrystallinity, photovoltaic technology, open-source-appropriate technology, and open-source hardware including RepRap 3D printers.

Boston Open Science Laboratory (BOSLab) is a labspace in Somerville, Massachusetts, which is part of the DIYbio and biohacking movement.

Tekla Labs (TeklaLabs.org) is a non-profit organization of researchers, educators and hobbyists committed to developing do it yourself (DIY) science infrastructure. Tekla Labs objective is to "enable scientists to construct their own high quality lab equipment using readily available, off the shelf items." Tekla Labs has been featured in numerous publications, including in MAKE, TechHive, Nature.com Blogs, New Scientist, and SciDev.Net.

A recyclebot is an open-source hardware device for converting waste plastic into filament for open-source 3D printers like the RepRap. Making DIY 3D printer filament at home is both less costly and better for the environment than purchasing conventional 3D printer filament. In following the RepRap tradition there are recyclebot designs that use mostly 3-D printable parts.

Fused filament fabrication (FFF), also known as fused deposition modeling, or filament freeform fabrication, is a 3D printing process that uses a continuous filament of a thermoplastic material. Filament is fed from a large spool through a moving, heated printer extruder head, and is deposited on the growing work. The print head is moved under computer control to define the printed shape. Usually the head moves in two dimensions to deposit one horizontal plane, or layer, at a time; the work or the print head is then moved vertically by a small amount to begin a new layer. The speed of the extruder head may also be controlled to stop and start deposition and form an interrupted plane without stringing or dribbling between sections. "Fused filament fabrication" was coined by the members of the RepRap project to give an acronym (FFF) that would be legally unconstrained in its use.

In recent years, 3D printing has developed significantly and can now perform crucial roles in many applications, with the most common applications being manufacturing, medicine, architecture, custom art and design, and can vary from fully functional to purely aesthetic applications.

A variety of processes, equipment, and materials are used in the production of a three-dimensional object via additive manufacturing. 3D printing is also known as additive manufacturing, because the numerous available 3D printing process tend to be additive in nature, with a few key differences in the technologies and the materials used in this process.