In organic chemistry, a hydrocarbon is an organic compound consisting entirely of hydrogen and carbon. Hydrocarbons are examples of group 14 hydrides. Hydrocarbons are generally colourless and hydrophobic, and their odors are usually weak or exemplified by the odors of gasoline and lighter fluid. They occur in a diverse range of molecular structures and phases: they can be gases, liquids, low melting solids or polymers.

Gasoline or petrol is a transparent, petroleum-derived flammable liquid that is used primarily as a fuel in most spark-ignited internal combustion engines. It consists mostly of organic compounds obtained by the fractional distillation of petroleum, enhanced with a variety of additives. On average, U.S. refineries produce, from a barrel of crude oil, about 19 to 20 gallons of gasoline; 11 to 13 gallons of distillate fuel ; and 3 to 4 gallons of jet fuel. The product ratio depends on the processing in an oil refinery and the crude oil assay. A barrel of oil is defined as holding 42 US gallons, which is about 159 liters or 35 imperial gallons.

Naphtha is a flammable liquid hydrocarbon mixture.

An oil refinery or petroleum refinery is an industrial process plant where petroleum is transformed and refined into useful products such as gasoline (petrol), diesel fuel, asphalt base, fuel oils, heating oil, kerosene, liquefied petroleum gas and petroleum naphtha. Petrochemicals feedstock like ethylene and propylene can also be produced directly by cracking crude oil without the need of using refined products of crude oil such as naphtha. The crude oil feedstock has typically been processed by an oil production plant. There is usually an oil depot at or near an oil refinery for the storage of incoming crude oil feedstock as well as bulk liquid products. In 2020, the total capacity of global refineries for crude oil was about 101.2 million barrels per day.

In petrochemistry, petroleum geology and organic chemistry, cracking is the process whereby complex organic molecules such as kerogens or long-chain hydrocarbons are broken down into simpler molecules such as light hydrocarbons, by the breaking of carbon-carbon bonds in the precursors. The rate of cracking and the end products are strongly dependent on the temperature and presence of catalysts. Cracking is the breakdown of a large alkane into smaller, more useful alkenes. Simply put, hydrocarbon cracking is the process of breaking a long chain of hydrocarbons into short ones. This process requires high temperatures.

Natural-gas condensate, also called natural gas liquids, is a low-density mixture of hydrocarbon liquids that are present as gaseous components in the raw natural gas produced from many natural gas fields. Some gas species within the raw natural gas will condense to a liquid state if the temperature is reduced to below the hydrocarbon dew point temperature at a set pressure.

A visbreaker is a processing unit in an oil refinery whose purpose is to reduce the quantity of residual oil produced in the distillation of crude oil and to increase the yield of more valuable middle distillates by the refinery. A visbreaker thermally cracks large hydrocarbon molecules in the oil by heating in a furnace to reduce its viscosity and to produce small quantities of light hydrocarbons.. The process name of "visbreaker" refers to the fact that the process reduces the viscosity of the residual oil. The process is non-catalytic.

Catalytic reforming is a chemical process used to convert petroleum refinery naphthas distilled from crude oil into high-octane liquid products called reformates, which are premium blending stocks for high-octane gasoline. The process converts low-octane linear hydrocarbons (paraffins) into branched alkanes (isoparaffins) and cyclic naphthenes, which are then partially dehydrogenated to produce high-octane aromatic hydrocarbons. The dehydrogenation also produces significant amounts of byproduct hydrogen gas, which is fed into other refinery processes such as hydrocracking. A side reaction is hydrogenolysis, which produces light hydrocarbons of lower value, such as methane, ethane, propane and butanes.

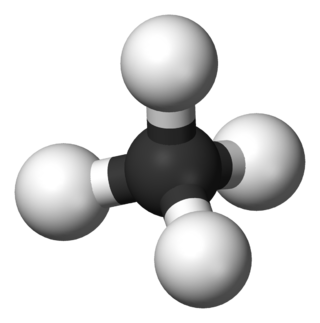

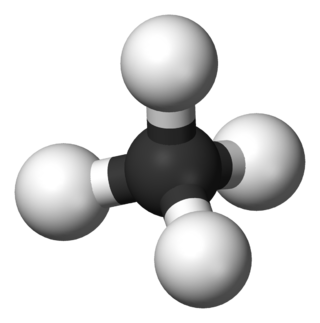

Gas to liquids (GTL) is a refinery process to convert natural gas or other gaseous hydrocarbons into longer-chain hydrocarbons, such as gasoline or diesel fuel. Methane-rich gases are converted into liquid synthetic fuels. Two general strategies exist: (i) direct partial combustion of methane to methanol and (ii) Fischer–Tropsch-like processes that convert carbon monoxide and hydrogen into hydrocarbons. Strategy ii is followed by diverse methods to convert the hydrogen-carbon monoxide mixtures to liquids. Direct partial combustion has been demonstrated in nature but not replicated commercially. Technologies reliant on partial combustion have been commercialized mainly in regions where natural gas is inexpensive.

Continuous distillation, a form of distillation, is an ongoing separation in which a mixture is continuously fed into the process and separated fractions are removed continuously as output streams. Distillation is the separation or partial separation of a liquid feed mixture into components or fractions by selective boiling and condensation. The process produces at least two output fractions. These fractions include at least one volatile distillate fraction, which has boiled and been separately captured as a vapor condensed to a liquid, and practically always a bottoms fraction, which is the least volatile residue that has not been separately captured as a condensed vapor.

Fluid Catalytic Cracking (FCC) is the conversion process used in petroleum refineries to convert the high-boiling point, high-molecular weight hydrocarbon fractions of petroleum into gasoline, olefinic gases, and other petroleum products. The cracking of petroleum hydrocarbons was originally done by thermal cracking, now virtually replaced by catalytic cracking, which yields greater volumes of high octane rating gasoline; and produces by-product gases, with more carbon-carbon double bonds, that are of greater economic value than the gases produced by thermal cracking.

Hydrocarbon mixtures are a group of various volatile, highly flammable, mixtures used chiefly as nonpolar solvents.

Hydroskimming is one of the simplest types of refinery used in the petroleum industry and still represents a large proportion of refining facilities, particularly in developing countries. A hydroskimming refinery is defined as a refinery equipped with atmospheric distillation, naphtha reforming and necessary treating processes. A hydroskimming refinery is therefore more complex than a topping refinery and it produces gasoline. The addition of catalytic reformer enables a hydroskimming refinery to generate higher octane reformate; benzene, toluene, and xylene; and hydrogen for hydrotreating units. However, a hydroskimming refinery produces a surplus of fuel with a relatively unattractive price and demand.

The BPRefinery (Kent) was an oil refinery on the Isle of Grain in Kent. It was commissioned in 1953 and had a maximum processing capacity of 11 million tonnes of crude oil per year. It was decommissioned in August 1982.

Crude oil is extracted from the bedrock before being processed in several stages, removing natural contaminants and undesirable hydrocarbons. This separation process produces mineral oil, which can in turn be denoted as paraffinic, naphthenic or aromatic. The differences between these different types of oils are not clear-cut, but mainly depend on the predominant hydrocarbon types in the oil. Paraffinic oil, for example, contains primarily higher alkanes, whereas naphthenic oils have a high share of cyclic alkanes in the mixture.

The PONA number is an index for oil components. It is used to determine the paraffins (P), olefins (O), naphthenes (N) and aromatics (A) content of FCC and coker (visbreaker) gasoline.

Petroleum refining processes are the chemical engineering processes and other facilities used in petroleum refineries to transform crude oil into useful products such as liquefied petroleum gas (LPG), gasoline or petrol, kerosene, jet fuel, diesel oil and fuel oils.

In the petroleum refining and petrochemical industries, the initialism BTX refers to mixtures of benzene, toluene, and the three xylene isomers, all of which are aromatic hydrocarbons. The xylene isomers are distinguished by the designations ortho –, meta –, and para – as indicated in the adjacent diagram. If ethylbenzene is included, the mixture is sometimes referred to as BTEX.

Syngas to gasoline plus (STG+) is a thermochemical process to convert natural gas, other gaseous hydrocarbons or gasified biomass into drop-in fuels, such as gasoline, diesel fuel or jet fuel, and organic solvents.

Petroleum benzine is a hydrocarbon-based solvent mixture that is classified by its physical properties rather than a specific chemical composition. This complicates distinction within the long list of petroleum distillate solvent mixtures: mineral spirits, naphtha, petroleum naptha, white gas, white spirits, turps substitute, mineral turpentine, petroleum ether, ligroin, and Stoddard solvent.