This article needs additional citations for verification .(May 2017) |

A plant layout study is an engineering study used to analyze different physical configurations for a manufacturing plant. [1] It is also known as Facilities Planning and Layout.

This article needs additional citations for verification .(May 2017) |

A plant layout study is an engineering study used to analyze different physical configurations for a manufacturing plant. [1] It is also known as Facilities Planning and Layout.

The ability to design and operate manufacturing facilities that can quickly and effectively adapt to changing technological and market requirements is becoming increasingly important to the success of any manufacturing organization. In the face of shorter product life cycles, higher product variety, increasingly unpredictable demand, and shorter delivery times, manufacturing facilities dedicated to a single product line cannot be cost effective any longer. Investment efficiency now requires that manufacturing facilities be able to shift quickly from one product line to another without major retooling, resource reconfiguration, or replacement of equipment.

Investment efficiency also requires that manufacturing facilities be able to simultaneously make several products so that smaller volume products can be combined in a single facility and that fluctuations in product mixes and volumes can be more easily accommodated. In short, manufacturing facilities must be able to exhibit high levels of flexibility and robustness despite significant changes in their operating requirements.

In industry sectors, it is important to manufacture the products which have good quality and meet customers’ demand. This action could be conducted under existing resources such as employees, machines and other facilities. However, plant layout improvement, could be one of the tools to response to increasing industrial productivity. Plant layout design has become a fundamental basis of today’s industrial plants which can influence parts of work efficiency. It is needed to appropriately plan and position employees, materials, machines, equipment, and other manufacturing supports and facilities to create the most effective plant layout.

The intended products to be manufactured influence the choice of layout.

Material requirements planning (MRP) is a production planning, scheduling, and inventory control system used to manage manufacturing processes. Most MRP systems are software-based, but it is possible to conduct MRP by hand as well.

Lean manufacturing is a production method aimed primarily at reducing times within the production system as well as response times from suppliers and to customers.

An office is a space where an organization's employees perform administrative work in order to support and realize objects and goals of the organization. The word "office" may also denote a position within an organization with specific duties attached to it ; the latter is in fact an earlier usage, office as place originally referring to the location of one's duty. When used as an adjective, the term "office" may refer to business-related tasks. In law, a company or organization has offices in any place where it has an official presence, even if that presence consists of a storage silo rather than an establishment with desk-and-chair. An office is also an architectural and design phenomenon: ranging from a small office such as a bench in the corner of a small business of extremely small size, through entire floors of buildings, up to and including massive buildings dedicated entirely to one company. In modern terms an office is usually the location where white-collar workers carry out their functions. According to James Stephenson, "Office is that part of business enterprise which is devoted to the direction and co-ordination of its various activities."

Facility management, or facilities management, (FM) is a professional management discipline focused on the efficient and effective delivery of logistics and other support services related to real property, it encompasses multiple disciplines to ensure functionality, comfort, safety and efficiency of the built environment by integrating people, place, process and technology, as defined by the International Organization for Standardization (ISO). The profession is certified through Global Facility Management Association member organizations.

Facilities engineering evolved from "plant engineering" in the early 1990s as U.S. workplaces became more specialized. Practitioners preferred this term because it more accurately reflected the multidisciplinary demands for specialized conditions in a wider variety of indoor environments, not merely manufacturing plants.

A distribution center for a set of products is a warehouse or other specialized building, often with refrigeration or air conditioning, which is stocked with products (goods) to be redistributed to retailers, to wholesalers, or directly to consumers. A distribution center is a principal part, the order processing element, of the entire order fulfillment process. Distribution centers are usually thought of as being demand driven. A distribution center can also be called a warehouse, a DC, a fulfillment center, a cross-dock facility, a bulk break center, and a package handling center. The name by which the distribution center is known is commonly based on the purpose of the operation. For example, a "retail distribution center" normally distributes goods to retail stores, an "order fulfillment center" commonly distributes goods directly to consumers, and a cross-dock facility stores little or no product but distributes goods to other destinations.

A chemical plant is an industrial process plant that manufactures chemicals, usually on a large scale. The general objective of a chemical plant is to create new material wealth via the chemical or biological transformation and or separation of materials. Chemical plants use specialized equipment, units, and technology in the manufacturing process. Other kinds of plants, such as polymer, pharmaceutical, food, and some beverage production facilities, power plants, oil refineries or other refineries, natural gas processing and biochemical plants, water and wastewater treatment, and pollution control equipment use many technologies that have similarities to chemical plant technology such as fluid systems and chemical reactor systems. Some would consider an oil refinery or a pharmaceutical or polymer manufacturer to be effectively a chemical plant.

Operations management is an area of management concerned with designing and controlling the process of production and redesigning business operations in the production of goods or services. It involves the responsibility of ensuring that business operations are efficient in terms of using as few resources as needed and effective in meeting customer requirements.

Computer-aided production engineering (CAPE) is a relatively new and significant branch of engineering. Global manufacturing has changed the environment in which goods are produced. Meanwhile, the rapid development of electronics and communication technologies has required design and manufacturing to keep pace.

In chemical engineering, process design is the choice and sequencing of units for desired physical and/or chemical transformation of materials. Process design is central to chemical engineering, and it can be considered to be the summit of that field, bringing together all of the field's components.

Capacity planning is the process of determining the production capacity needed by an organization to meet changing demands for its products. In the context of capacity planning, design capacity is the maximum amount of work that an organization is capable of completing in a given period. Effective capacity is the maximum amount of work that an organization is capable of completing in a given period due to constraints such as quality problems, delays, material handling, etc.

Supply-chain optimization (SCO) aims to ensure the optimal operation of a manufacturing and distribution supply chain. This includes the optimal placement of inventory within the supply chain, minimizing operating costs including manufacturing costs, transportation costs, and distribution costs. Optimization often involves the application of mathematical modelling techniques using computer software. It is often considered to be part of supply chain engineering, although the latter is mainly focused on mathematical modelling approaches, whereas supply chain optimization can also be undertaken using qualitative, management based approaches.

SMTC Corporation, founded in 1985, is a mid-size provider of end-to-end electronics manufacturing services (EMS) including PCBA production, systems integration and comprehensive testing services, enclosure fabrication, as well as product design, sustaining engineering and supply chain management services. SMTC facilities span a broad footprint in the United States, Canada, Mexico, and China, with more than 2,300 employees. SMTC services extend over the entire electronic product life cycle from the development and introduction of new products through to the growth, maturity and end-of-life phases. SMTC offers fully integrated contract manufacturing services with a distinctive approach to global original equipment manufacturers (OEMs) and emerging technology companies primarily within industrial, computing and communication market segments. SMTC was recognized in 2012 by Frost & Sullivan with the Global EMS Award for Product Quality Leadership and 2013 with the North American Growth Leadership Award in the EMS industry, as one of the fastest growth companies in 2012.

Cellular manufacturing is a process of manufacturing which is a subsection of just-in-time manufacturing and lean manufacturing encompassing group technology. The goal of cellular manufacturing is to move as quickly as possible, make a wide variety of similar products, while making as little waste as possible. Cellular manufacturing involves the use of multiple "cells" in an assembly line fashion. Each of these cells is composed of one or multiple different machines which accomplish a certain task. The product moves from one cell to the next, each station completing part of the manufacturing process. Often the cells are arranged in a "U-shape" design because this allows for the overseer to move less and have the ability to more readily watch over the entire process. One of the biggest advantages of cellular manufacturing is the amount of flexibility that it has. Since most of the machines are automatic, simple changes can be made very rapidly. This allows for a variety of scaling for a product, minor changes to the overall design, and in extreme cases, entirely changing the overall design. These changes, although tedious, can be accomplished extremely quickly and precisely.

An energy audit is an inspection survey and an analysis of energy flows for energy conservation in a building. It may include a process or system to reduce the amount of energy input into the system without negatively affecting the output. In commercial and industrial real estate, an energy audit is the first step in identifying opportunities to reduce energy expense and carbon footprint.

Industrial Engineering is an engineering profession that is concerned with the optimization of complex processes, systems, or organizations by developing, improving and implementing integrated systems of people, money, knowledge, information and equipment. Industrial engineering is central to manufacturing operations.

Environmentally sustainable design is the philosophy of designing physical objects, the built environment, and services to comply with the principles of ecological sustainability.

Office space planning is the process of organizing the workplace layout, furniture and office functions to work effectively together, while using space efficiently. Floor plans should consider the workgroup function, building codes and regulations, lighting, teaming requirements, inter-communication and storage, as well as zoning for employee workstations, task space needs, support rooms and reception areas to make the best use of available space. Optimising office spaces with effective space planning can aid circulation, productivity and improve workplace wellness, as well as the health and safety of occupants.

Industrial and production engineering (IPE) is an interdisciplinary engineering discipline that includes manufacturing technology, engineering sciences, management science, and optimization of complex processes, systems, or organizations. It is concerned with the understanding and application of engineering procedures in manufacturing processes and production methods. Industrial engineering dates back all the way to the industrial revolution, initiated in 1700s by Sir Adam Smith, Henry Ford, Eli Whitney, Frank Gilbreth and Lilian Gilbreth, Henry Gantt, F.W. Taylor, etc. After the 1970s, industrial and production engineering developed worldwide and started to widely use automation and robotics. Industrial and production engineering includes three areas: Mechanical engineering, industrial engineering, and management science.

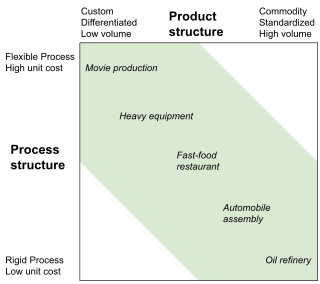

The Hayes-Wheelwright Matrix, also known as the product-process matrix, is a tool to analyze the fit between a chosen product positioning and manufacturing process.