Related Research Articles

Fiberglass or fibreglass is a common type of fiber-reinforced plastic using glass fiber. The fibers may be randomly arranged, flattened into a sheet called a chopped strand mat, or woven into glass cloth. The plastic matrix may be a thermoset polymer matrix—most often based on thermosetting polymers such as epoxy, polyester resin, or vinyl ester resin—or a thermoplastic.

Epoxy is the family of basic components or cured end products of epoxy resins. Epoxy resins, also known as polyepoxides, are a class of reactive prepolymers and polymers which contain epoxide groups. The epoxide functional group is also collectively called epoxy. The IUPAC name for an epoxide group is an oxirane.

In materials science, a thermosetting polymer, often called a thermoset, is a polymer that is obtained by irreversibly hardening ("curing") a soft solid or viscous liquid prepolymer (resin). Curing is induced by heat or suitable radiation and may be promoted by high pressure or mixing with a catalyst. Heat is not necessarily applied externally, and is often generated by the reaction of the resin with a curing agent. Curing results in chemical reactions that create extensive cross-linking between polymer chains to produce an infusible and insoluble polymer network.

Fibre-reinforced plastic is a composite material made of a polymer matrix reinforced with fibres. The fibres are usually glass, carbon, aramid, or basalt. Rarely, other fibres such as paper, wood, boron, or asbestos have been used. The polymer is usually an epoxy, vinyl ester, or polyester thermosetting plastic, though phenol formaldehyde resins are still in use.

Filament winding is a fabrication technique mainly used for manufacturing open (cylinders) or closed end structures. This process involves winding filaments under tension over a rotating mandrel. The mandrel rotates around the spindle while a delivery eye on a carriage traverses horizontally in line with the axis of the rotating mandrel, laying down fibers in the desired pattern or angle to the rotational axis. The most common filaments are glass or carbon and are impregnated with resin by passing through a bath as they are wound onto the mandrel. Once the mandrel is completely covered to the desired thickness, the resin is cured. Depending on the resin system and its cure characteristics, often the mandrel is autoclaved or heated in an oven or rotated under radiant heaters until the part is cured. Once the resin has cured, the mandrel is removed or extracted, leaving the hollow final product. For some products such as gas bottles, the 'mandrel' is a permanent part of the finished product forming a liner to prevent gas leakage or as a barrier to protect the composite from the fluid to be stored.

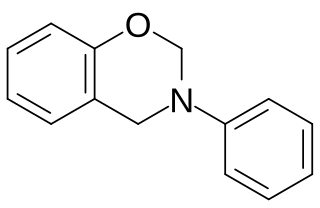

Polybenzoxazines, also called benzoxazine resins, are cured polymerization products derived from benzoxazine monomers.

Curing is a chemical process employed in polymer chemistry and process engineering that produces the toughening or hardening of a polymer material by cross-linking of polymer chains. Even if it is strongly associated with the production of thermosetting polymers, the term "curing" can be used for all the processes where a solid product is obtained from a liquid solution, such as with PVC plastisols.

Fiber volume ratio is an important mathematical element in composite engineering. Fiber volume ratio, or fiber volume fraction, is the percentage of fiber volume in the entire volume of a fiber-reinforced composite material. When manufacturing polymer composites, fibers are impregnated with resin. The amount of resin to fiber ratio is calculated by the geometric organization of the fibers, which affects the amount of resin that can enter the composite. The impregnation around the fibers is highly dependent on the orientation of the fibers and the architecture of the fibers. The geometric analysis of the composite can be seen in the cross-section of the composite. Voids are often formed in a composite structure throughout the manufacturing process and must be calculated into the total fiber volume fraction of the composite. The fraction of fiber reinforcement is very important in determining the overall mechanical properties of a composite. A higher fiber volume fraction typically results in better mechanical properties of the composite.

A thermoset polymer matrix is a synthetic polymer reinforcement where polymers act as binder or matrix to secure in place incorporated particulates, fibres or other reinforcements. They were first developed for structural applications, such as glass-reinforced plastic radar domes on aircraft and graphite-epoxy payload bay doors on the Space Shuttle.

Carbon fiber-reinforced polymers, carbon-fibre-reinforced polymers, carbon-fiber-reinforced plastics, carbon-fiber reinforced-thermoplastic, also known as carbon fiber, carbon composite, or just carbon, are extremely strong and light fiber-reinforced plastics that contain carbon fibers. CFRPs can be expensive to produce, but are commonly used wherever high strength-to-weight ratio and stiffness (rigidity) are required, such as aerospace, superstructures of ships, automotive, civil engineering, sports equipment, and an increasing number of consumer and technical applications.

Out of autoclave composite manufacturing is an alternative to the traditional high pressure autoclave (industrial) curing process commonly used by the aerospace manufacturers for manufacturing composite material. Out of autoclave (OOA) is a process that achieves the same quality as an autoclave but through a different process. OOA curing achieves the desired fiber content and elimination of voids by placing the layup within a closed mold and applying vacuum, pressure, and heat by means other than an autoclave. An RTM press is the typical method of applying heat and pressure to the closed mold. There are several out of autoclave technologies in current use including resin transfer molding (RTM), Same Qualified Resin Transfer Molding (SQRTM), vacuum-assisted resin transfer molding (VARTM), and balanced pressure fluid molding. The most advanced of these processes can produce high-tech net shape aircraft components.

Automated fiber placement (AFP), also known as advanced fiber placement, is an advanced method of manufacturing composite materials. These materials, which offer lighter weight with equivalent or greater strength than metals, are increasingly used in airframes and other industrial products.

Vacuum Assisted Resin Transfer Molding (VARTM) or Vacuum Injected Molding (VIM) is a closed mold, out of autoclave (OOA) composite manufacturing process. VARTM is a variation of Resin Transfer Molding (RTM) with its distinguishing characteristic being the replacement of the top portion of a mold tool with a vacuum bag and the use of a vacuum to assist in resin flow. The process involves the use of a vacuum to facilitate resin flow into a fiber layup contained within a mold tool covered by a vacuum bag. After the impregnation occurs the composite part is allowed to cure at room temperature with an optional post cure sometimes carried out.

A void or a pore is three-dimensional region that remains unfilled with polymer and fibers in a composite material. Voids are typically the result of poor manufacturing of the material and are generally deemed undesirable. Voids can affect the mechanical properties and lifespan of the composite. They degrade mainly the matrix-dominated properties such as interlaminar shear strength, longitudinal compressive strength, and transverse tensile strength. Voids can act as crack initiation sites as well as allow moisture to penetrate the composite and contribute to the anisotropy of the composite. For aerospace applications, a void content of approximately 1% is still acceptable, while for less sensitive applications, the allowance limit is 3-5%. Although a small increase in void content may not seem to cause significant issues, a 1-3% increase in void content of carbon fiber reinforced composite can reduce the mechanical properties by up to 20%

Transfer molding is a manufacturing process in which casting material is forced into a mold. Transfer molding is different from compression molding in that the mold is enclosed rather than open to the fill plunger resulting in higher dimensional tolerances and less environmental impact. Compared to injection molding, transfer molding uses higher pressures to uniformly fill the mold cavity. This allows thicker reinforcing fiber matrices to be more completely saturated by resin. Furthermore, unlike injection molding the transfer mold casting material may start the process as a solid. This can reduce equipment costs and time dependency. The transfer process may have a slower fill rate than an equivalent injection molding process.

CFSMC, or Carbon Fiber Sheet Molding Compound, is a ready to mold carbon fiber reinforced polymer composite material used in compression molding. While traditional SMC utilizes chopped glass fibers in a polymer resin, CFSMC utilizes chopped carbon fibers. The length and distribution of the carbon fibers is more regular, homogeneous, and constant than the standard glass SMC. CFSMC offers much higher stiffness and usually higher strength than standard SMC, but at a higher cost.

In materials science, a polymer matrix composite (PMC) is a composite material composed of a variety of short or continuous fibers bound together by a matrix of organic polymers. PMCs are designed to transfer loads between fibers of a matrix. Some of the advantages with PMCs include their light weight, high resistance to abrasion and corrosion, and high stiffness and strength along the direction of their reinforcements.

A Lay-Up process is a moulding process for composite materials, in which the final product is obtained by overlapping a specific number of different layers, usually made of continuous polymeric or ceramic fibres and a thermoset polymeric liquid matrix. It can be divided into Dry Lay-up and Wet Lay-Up, depending on whether the layers are pre-impregnated or not. Dry Lay-up is a common process in the aerospace industry, due to the possibility of obtaining complex shapes with good mechanical properties, characteristics required in this field. On the contrary, as Wet Lay-Up does not allow uni-directional fabrics, which have better mechanical properties, it is mainly adopted for all other areas, which in general have lower requirements in terms of performance.

The main stages of the Lay-Up process are cutting, lamination and polymerization. Even though some of the production steps can be automated, this process is mainly manual, leading to laminates with high production costs and low production rates with respect to other techniques. Hence, nowadays, it is mainly suitable for small series production runs of 10 to 1000 parts.

Autoclave moulding is an advanced composite manufacturing process.

In materials science, a matrix is a constituent of a composite material.

References

- ↑ Chawla, Krishan K. (2012). Composite Materials. New York, NY: Springer New York. Bibcode:2012coma.book.....C. doi:10.1007/978-0-387-74365-3. ISBN 978-0-387-74364-6. S2CID 199491314.

- ↑ Rusnákov, S (2018). "Overview of production of pre-preg, prototype and testing". IOP Conference Series: Materials Science and Engineering. XXIII International Conference on Manufacturing (Manufacturing 2018). 448 (1): 012069. Bibcode:2018MS&E..448a2069R. doi: 10.1088/1757-899X/448/1/012069 .

{{cite journal}}: CS1 maint: location (link) - ↑ Scola, Daniel A.; Vontell, John; Felsen, Marvin (August 1987). "Effects of ambient aging of 5245C/graphite prepreg on composition and mechanical properties of fabricated composites". Polymer Composites. 8 (4): 244–252. doi:10.1002/pc.750080406. ISSN 0272-8397.

- ↑ BOEING CO SEATTLE WA (1963-02-01). "Dyna Soar Testing for the Boeing Company". Fort Belvoir, VA. doi:10.21236/ad0336996.

{{cite journal}}: Cite journal requires|journal=(help) - ↑ Helmus, Rhena; Centea, Timotei; Hubert, Pascal; Hinterhölzl, Roland (2015-06-24). "Out-of-autoclave prepreg consolidation: Coupled air evacuation and prepreg impregnation modeling". Journal of Composite Materials. 50 (10): 1403–1413. doi:10.1177/0021998315592005. ISSN 0021-9983. S2CID 136977442.

- ↑ Citation error. See inline comment how to fix. [ verification needed ]

- ↑ K., Mazumdar, Sanjay (2002). Composites manufacturing : materials, product, and process engineering. Boca Raton, Fla.: CRC Press. ISBN 978-0849305856. OCLC 47825959.

{{cite book}}: CS1 maint: multiple names: authors list (link) - ↑ Pinkerton, Erin (2014). "Pairing Up in Prepreg; Gurit Partners with NAC to Grow Business in Prepreg Market" (PDF). cdn.coverstand.com. Louisville, KY: Innovative Publishing. pp. 32–33. Archived (PDF) from the original on October 6, 2021. Retrieved October 8, 2021.

- ↑ Murashov, V. V. (March 2012). "Control of multilayer glued constructions of polymeric composite materials". Polymer Science, Series D. 5 (2): 109–115. doi:10.1134/s1995421212020104. ISSN 1995-4212. S2CID 137124767.

- ↑ Centea, T.; Hubert, P. (March 2011). "Measuring the impregnation of an out-of-autoclave prepreg by micro-CT". Composites Science and Technology. 71 (5): 593–599. doi:10.1016/j.compscitech.2010.12.009. ISSN 0266-3538.

- ↑ "Out-of-autoclave prepregs: Hype or revolution?". Composites World. Retrieved 2011-01-03.