A quality management system (QMS) is a collection of business processes focused on consistently meeting customer requirements and enhancing their satisfaction. It is aligned with an organization's purpose and strategic direction. It is expressed as the organizational goals and aspirations, policies, processes, documented information, and resources needed to implement and maintain it. Early quality management systems emphasized predictable outcomes of an industrial product production line, using simple statistics and random sampling. By the 20th century, labor inputs were typically the most costly inputs in most industrialized societies, so focus shifted to team cooperation and dynamics, especially the early signaling of problems via a continual improvement cycle. In the 21st century, QMS has tended to converge with sustainability and transparency initiatives, as both investor and customer satisfaction and perceived quality are increasingly tied to these factors. Of QMS regimes, the ISO 9000 family of standards is probably the most widely implemented worldwide – the ISO 19011 audit regime applies to both and deals with quality and sustainability and their integration.

In commerce, supply chain management (SCM) deals with a system of procurement, operations management, logistics and marketing channels, through which raw materials can be developed into finished products and delivered to their end customers. A more narrow definition of supply chain management is the "design, planning, execution, control, and monitoring of supply chain activities with the objective of creating net value, building a competitive infrastructure, leveraging worldwide logistics, synchronising supply with demand and measuring performance globally". This can include the movement and storage of raw materials, work-in-process inventory, finished goods, and end to end order fulfilment from the point of origin to the point of consumption. Interconnected, interrelated or interlinked networks, channels and node businesses combine in the provision of products and services required by end customers in a supply chain.

In management accounting or managerial accounting, managers use accounting information in decision-making and to assist in the management and performance of their control functions.

Logistics is the part of supply chain management that deals with the efficient forward and reverse flow of goods, services, and related information from the point of origin to the point of consumption according to the needs of customers. Logistics management is a component that holds the supply chain together. The resources managed in logistics may include tangible goods such as materials, equipment, and supplies, as well as food and other consumable items.

Inventory or stock refers to the goods and materials that a business holds for the ultimate goal of resale, production or utilisation.

A supply chain, sometimes expressed as a "supply-chain", is a complex logistics system that consists of facilities that convert raw materials into finished products and distribute them to end consumers or end customers. Meanwhile, supply chain management deals with the flow of goods within the supply chain in the most efficient manner.

Six Sigma (6σ) is a set of techniques and tools for process improvement. It was introduced by American engineer Bill Smith while working at Motorola in 1986.

Kaizen is a concept referring to business activities that continuously improve all functions and involve all employees from the CEO to the assembly line workers. Kaizen also applies to processes, such as purchasing and logistics, that cross organizational boundaries into the supply chain. It has been applied in healthcare, psychotherapy, life coaching, government, manufacturing, and banking.

A value chain is a progression of activities that a business or firm performs in order to deliver goods and services of value to an end customer. The concept comes from the field of business management and was first described by Michael Porter in his 1985 best-seller, Competitive Advantage: Creating and Sustaining Superior Performance.

The idea of [Porter's Value Chain] is based on the process view of organizations, the idea of seeing a manufacturing organization as a system, made up of subsystems each with inputs, transformation processes and outputs. Inputs, transformation processes, and outputs involve the acquisition and consumption of resources – money, labour, materials, equipment, buildings, land, administration and management. How value chain activities are carried out determines costs and affects profits.

Activity-based costing (ABC) is a costing method that identifies activities in an organization and assigns the cost of each activity to all products and services according to the actual consumption by each. Therefore, this model assigns more indirect costs (overhead) into direct costs compared to conventional costing.

A performance indicator or key performance indicator (KPI) is a type of performance measurement. KPIs evaluate the success of an organization or of a particular activity in which it engages. KPIs provide a focus for strategic and operational improvement, create an analytical basis for decision making and help focus attention on what matters most.

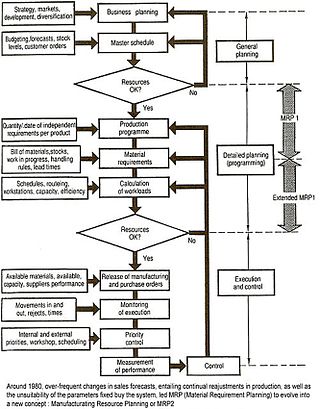

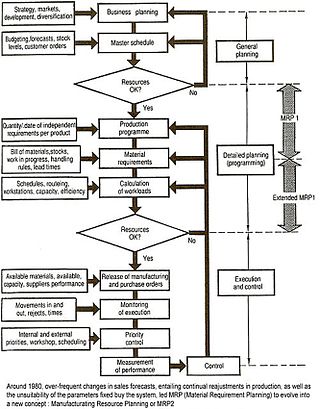

Manufacturingresource planning is a method for the effective planning of all resources of a manufacturing company. Ideally, it addresses operational planning in units, financial planning, and has a simulation capability to answer "what-if" questions and is an extension of closed-loop MRP.

Operations management is concerned with designing and controlling the production of goods and services, ensuring that businesses are efficient in using resources to meet customer requirements.

A contract manufacturer (CM) is a manufacturer that contracts with a firm for components or products. It is a form of outsourcing. A contract manufacturer performing packaging operations is called copacker or a contract packager. Brand name companies focus on product innovation, design and sales, while the manufacturing takes place in independent factories.

Materials management is a core supply chain function and includes supply chain planning and supply chain execution capabilities. Specifically, materials management is the capability firms use to plan total material requirements. The material requirements are communicated to procurement and other functions for sourcing. Materials management is also responsible for determining the amount of material to be deployed at each stocking location across the supply chain, establishing material replenishment plans, determining inventory levels to hold for each type of inventory, and communicating information regarding material needs throughout the extended supply chain.

In business, engineering, and manufacturing, quality – or high quality – has a pragmatic interpretation as the non-inferiority or superiority of something ; it is also defined as being suitable for the intended purpose while satisfying customer expectations. Quality is a perceptual, conditional, and somewhat subjective attribute and may be understood differently by different people. Consumers may focus on the specification quality of a product/service, or how it compares to competitors in the marketplace. Producers might measure the conformance quality, or degree to which the product/service was produced correctly. Support personnel may measure quality in the degree that a product is reliable, maintainable, or sustainable. In such ways, the subjectivity of quality is rendered objective via operational definitions and measured with metrics such as proxy measures.

Production is the process of combining various inputs, both material and immaterial in order to create output. Ideally this output will be a good or service which has value and contributes to the utility of individuals. The area of economics that focuses on production is called production theory, and it is closely related to the consumption theory of economics.

Management accounting in supply chains is part of the supply chain management concept. This necessitates planning, monitoring, management and information about logistics and manufacturing processes throughout the value chain. The goal of management accounting in supply chains is to optimise these processes. This strategy focuses on supporting management.

Operations management for services has the functional responsibility for producing the services of an organization and providing them directly to its customers. It specifically deals with decisions required by operations managers for simultaneous production and consumption of an intangible product. These decisions concern the process, people, information and the system that produces and delivers the service. It differs from operations management in general, since the processes of service organizations differ from those of manufacturing organizations.